Gravity Equipment

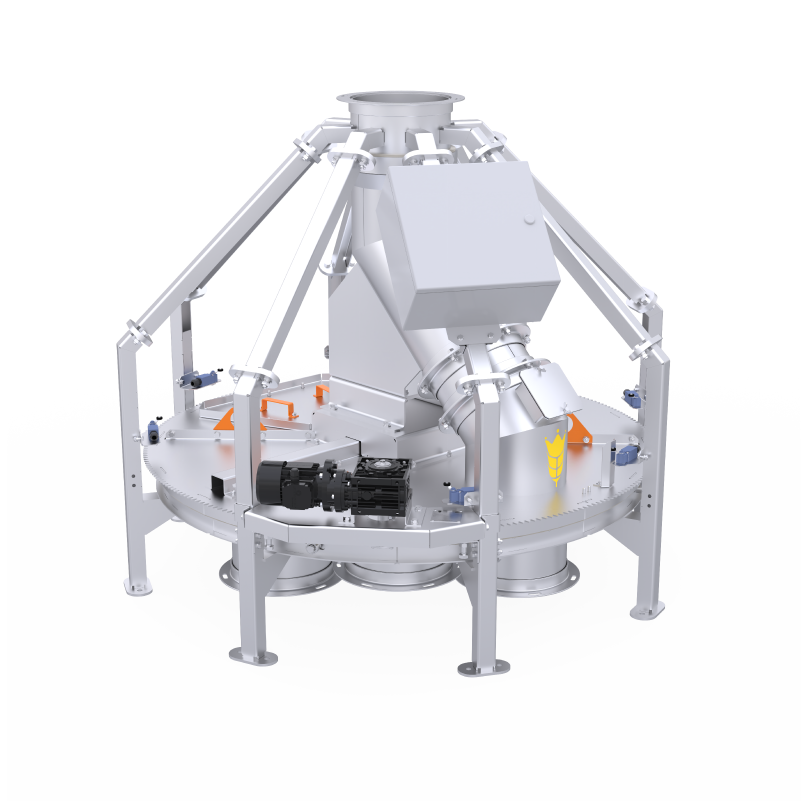

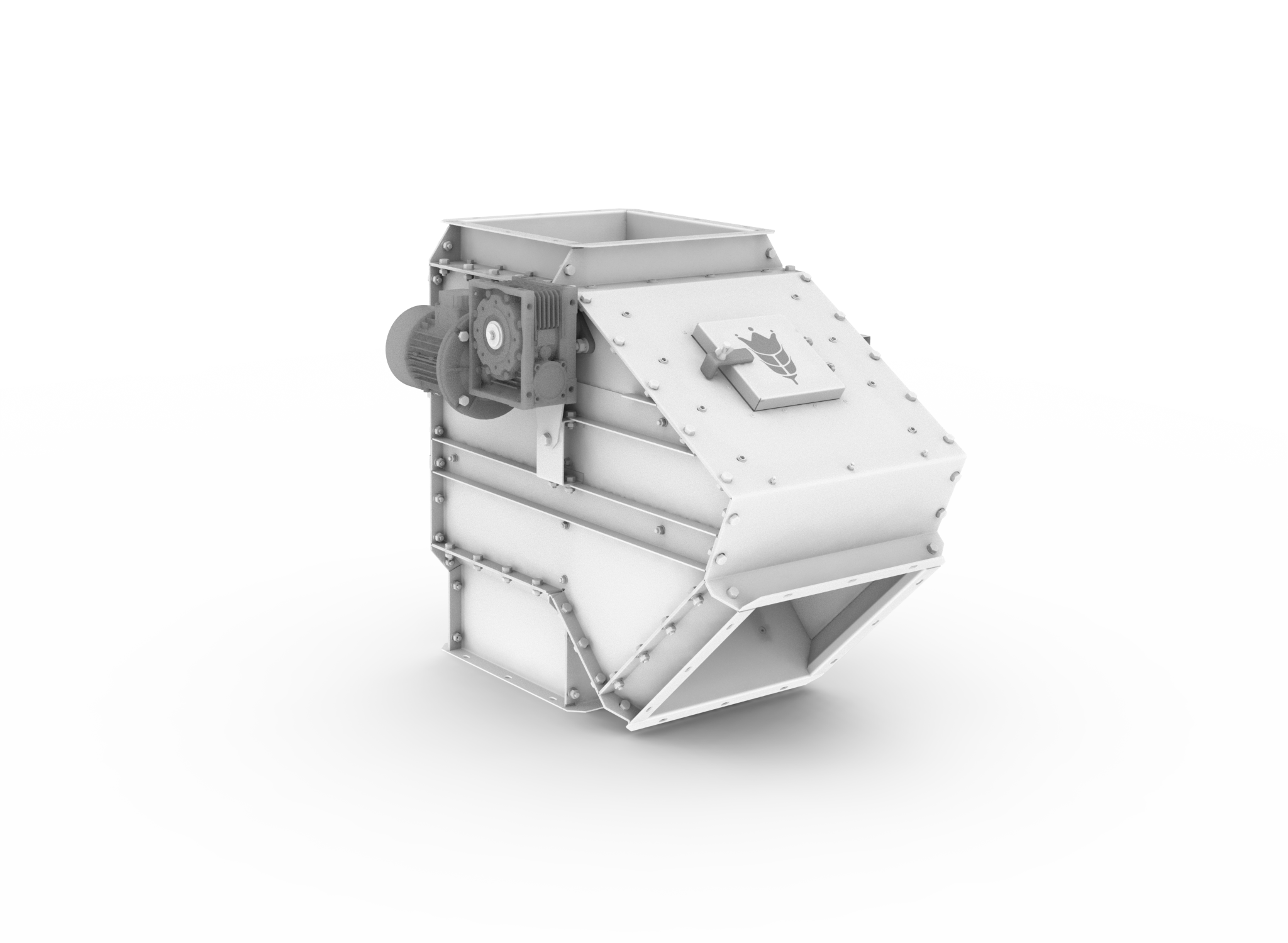

Moving grain efficiently affects the performance and downtime of your company. The grain flow divider or distributor is intended to select the bulk product flow in one of 4, 6, or 8 predefined directions. The distributor is equipped with position sensors for precise device positioning and efficient route reconfiguration.

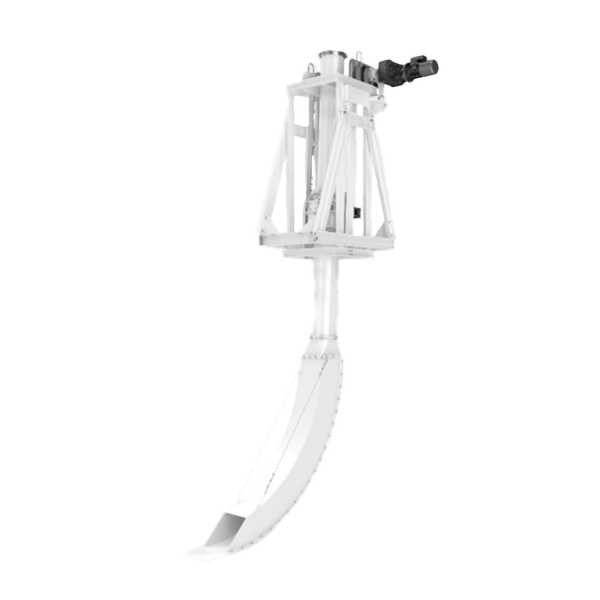

The stuffing pipe is intended for loading containers with bulk materials. The discharge tube is adjustable in height and angle.

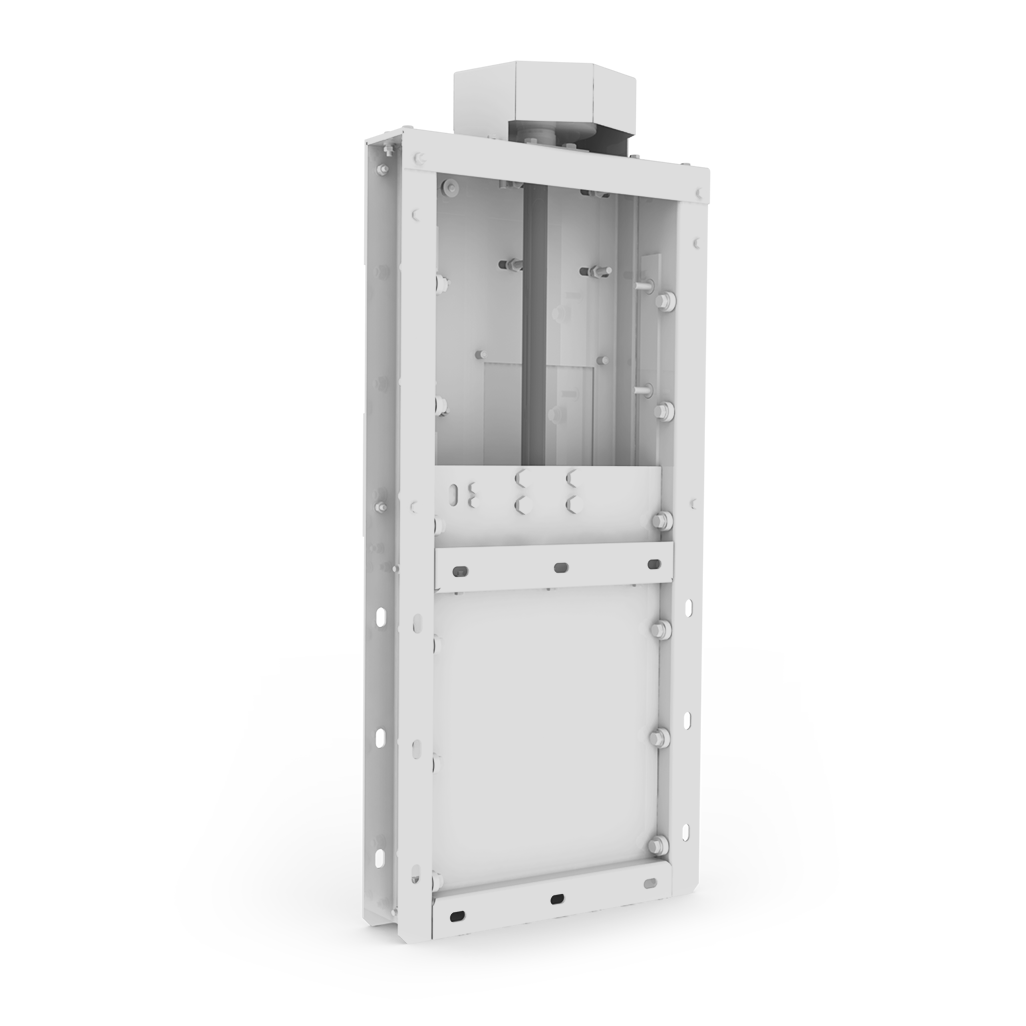

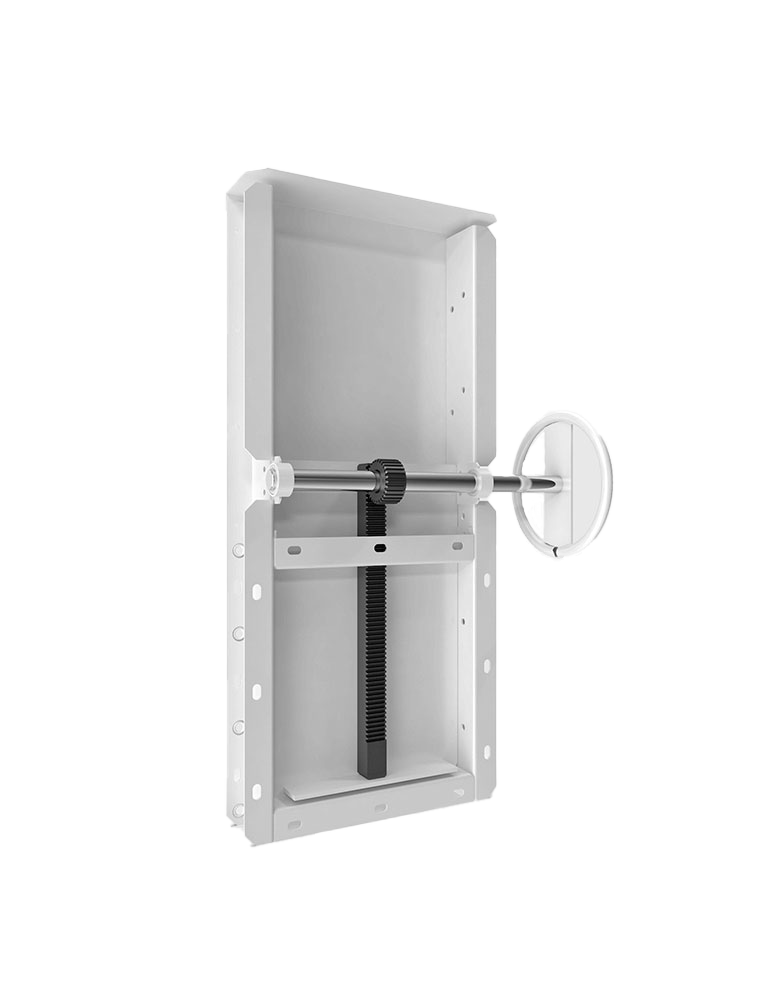

It is installed in places of unloading storage tanks, hoppers, warehouses, and granaries. The gear motor drives the traction screw, which ensures the deflector movement (opening/closing).

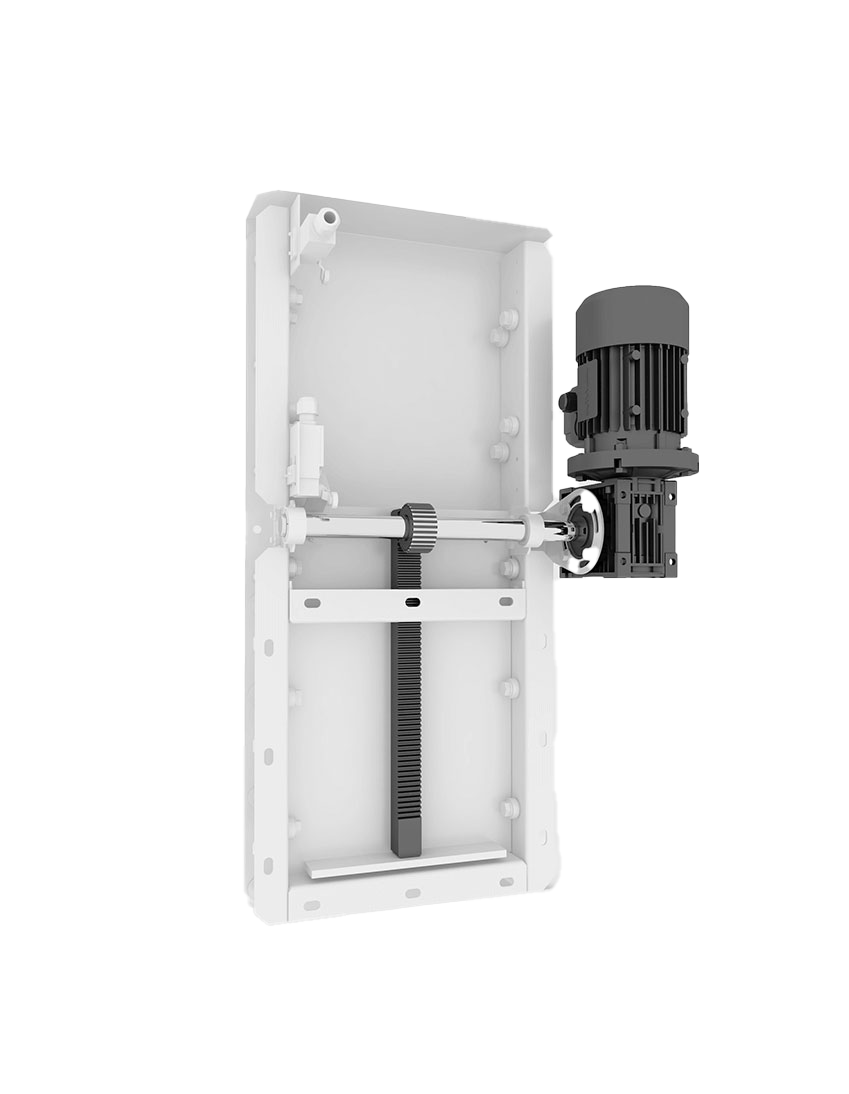

It is installed in places of unloading storage tanks, hoppers, warehouses, and granaries. The gear motor powers a drive shaft with a gear, which drives the gate movement (opening/closing) through a gear rack.

It is installed in places of unloading storage tanks, hoppers, warehouses, and granaries. The deflector moves along the guide rollers (minimized movement resistance) and opens (closes) the discharge hopper.

It is designed to change the flow of grain and its derivatives. It can be installed in places where a product flow needs to be divided into two or three directions. The valves are manufactured in a bucket design, thus preserving the full crosscut and preventing product spillage. The valves are equipped with terminal switches of the bucket end position, thus allowing remote control.

It is designed to change the flow of grain and its derivatives. It can be installed in places where a product flow needs to be divided into two or three directions. The valves are manufactured in a bucket design, thus preserving the full crosscut and preventing product spillage.

Questions you may have?