Transportation Equipment

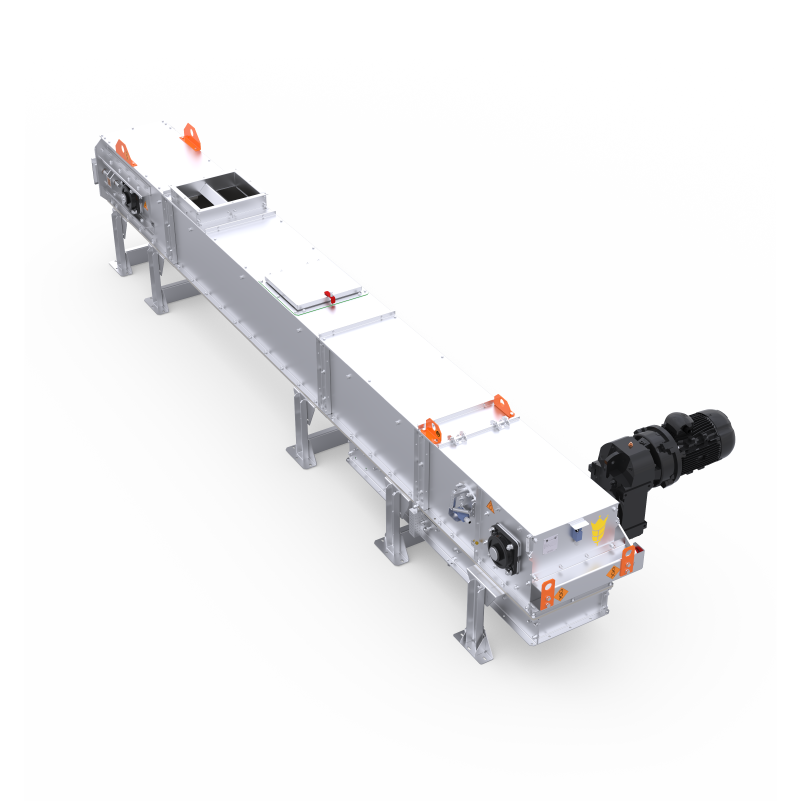

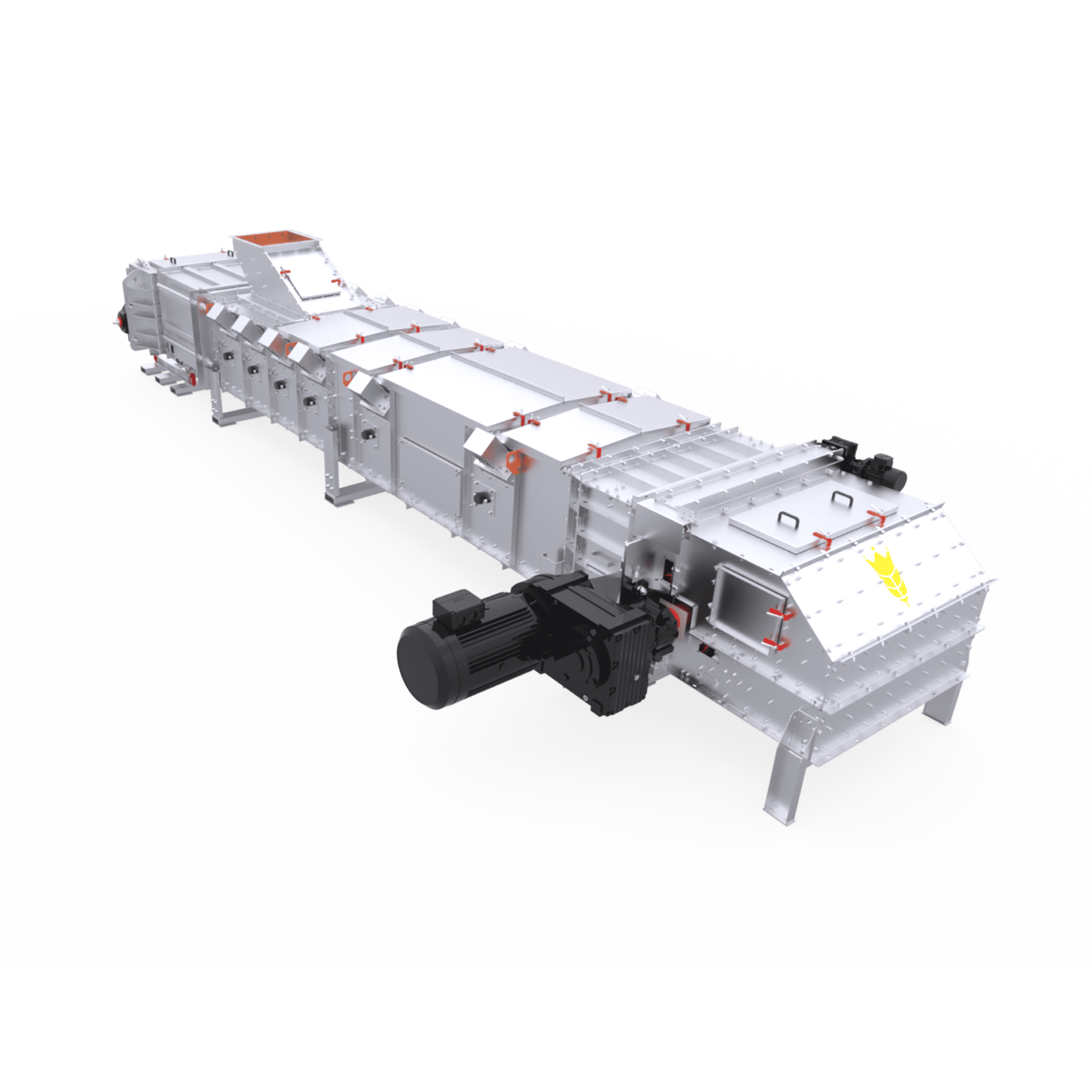

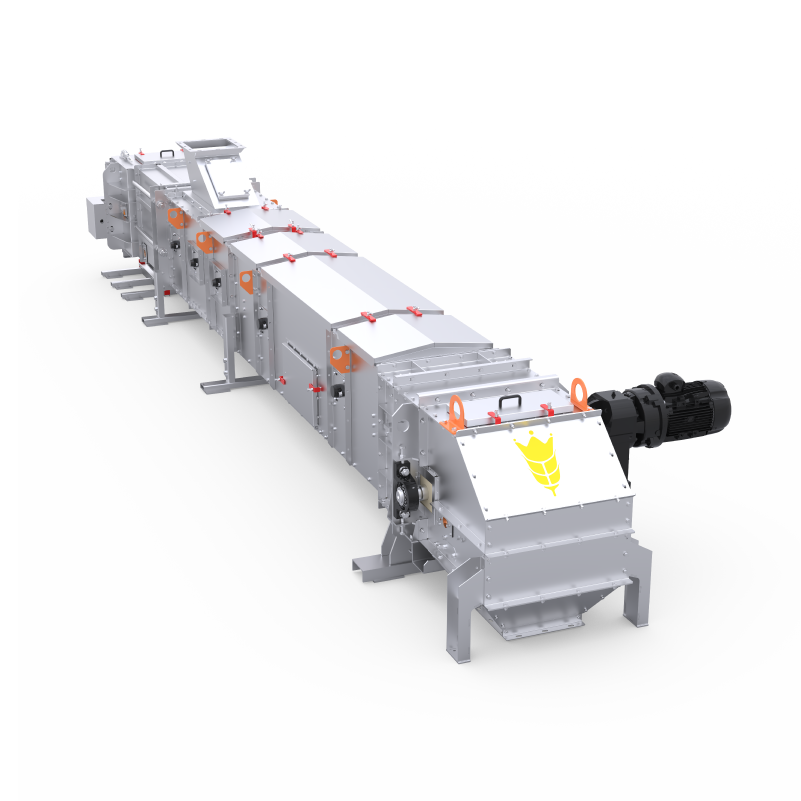

Chain Conveyors

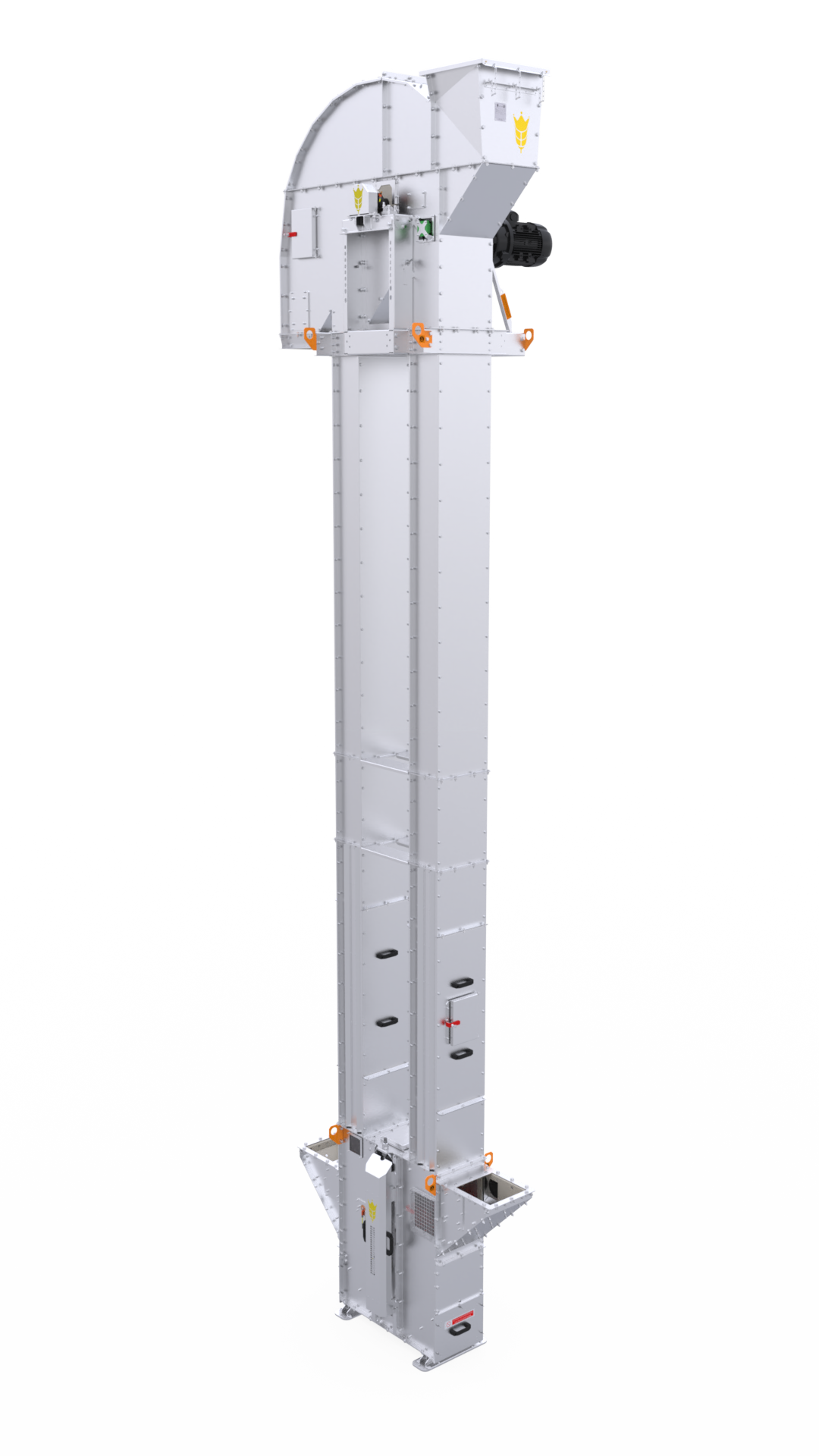

Bucket Elevators

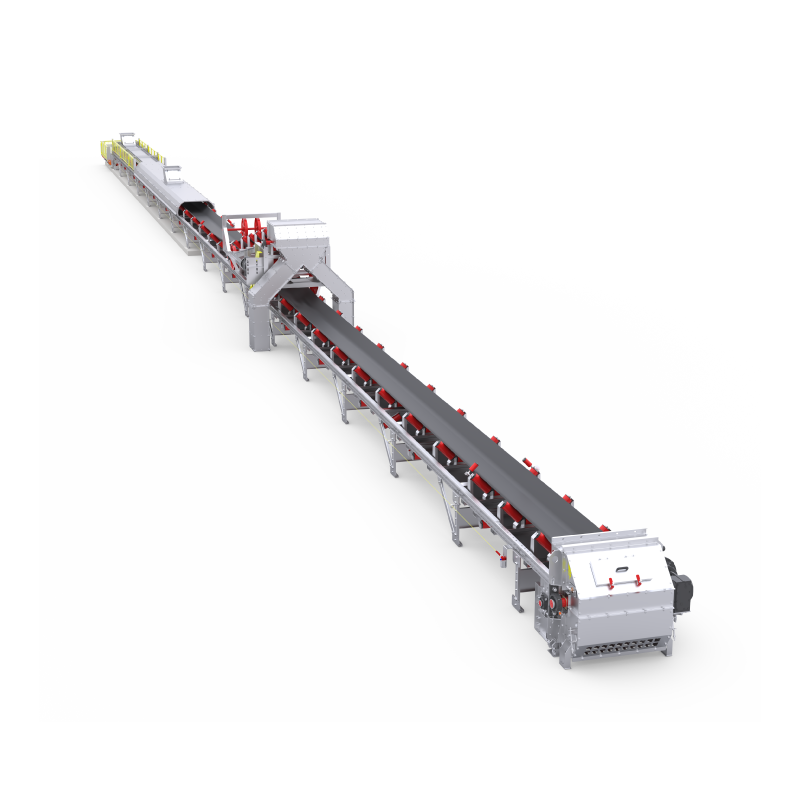

Belt Conveyors

A belt conveyor is a continuously operating conveying device with a working unit in the form of a belt. It is used for transporting bulk cargo in horizontal, inclined (from -10° to + 22°), and horizontal-inclined positions. When moving grain, gentle transportation modes and minimal damage are ensured.

An enclosed belt conveyor is a continuously operating conveying device with a working unit in the form of a belt. It is used for transporting bulk cargo in horizontal, inclined (from -10° to + 22°), and horizontal-inclined positions. The enclosed belt conveyor is characterized by specially designed support rollers for the loaded strand, where the bearings are removed from the dust accumulation zone.

A reel enclosed belt conveyor is a continuously operating conveying device with a working unit in the form of a belt. It is used for transporting bulk cargo in horizontal, inclined (from -10° to + 22°), and horizontal-inclined positions.

Mobile Belt Conveyors

Sweep Conveyors

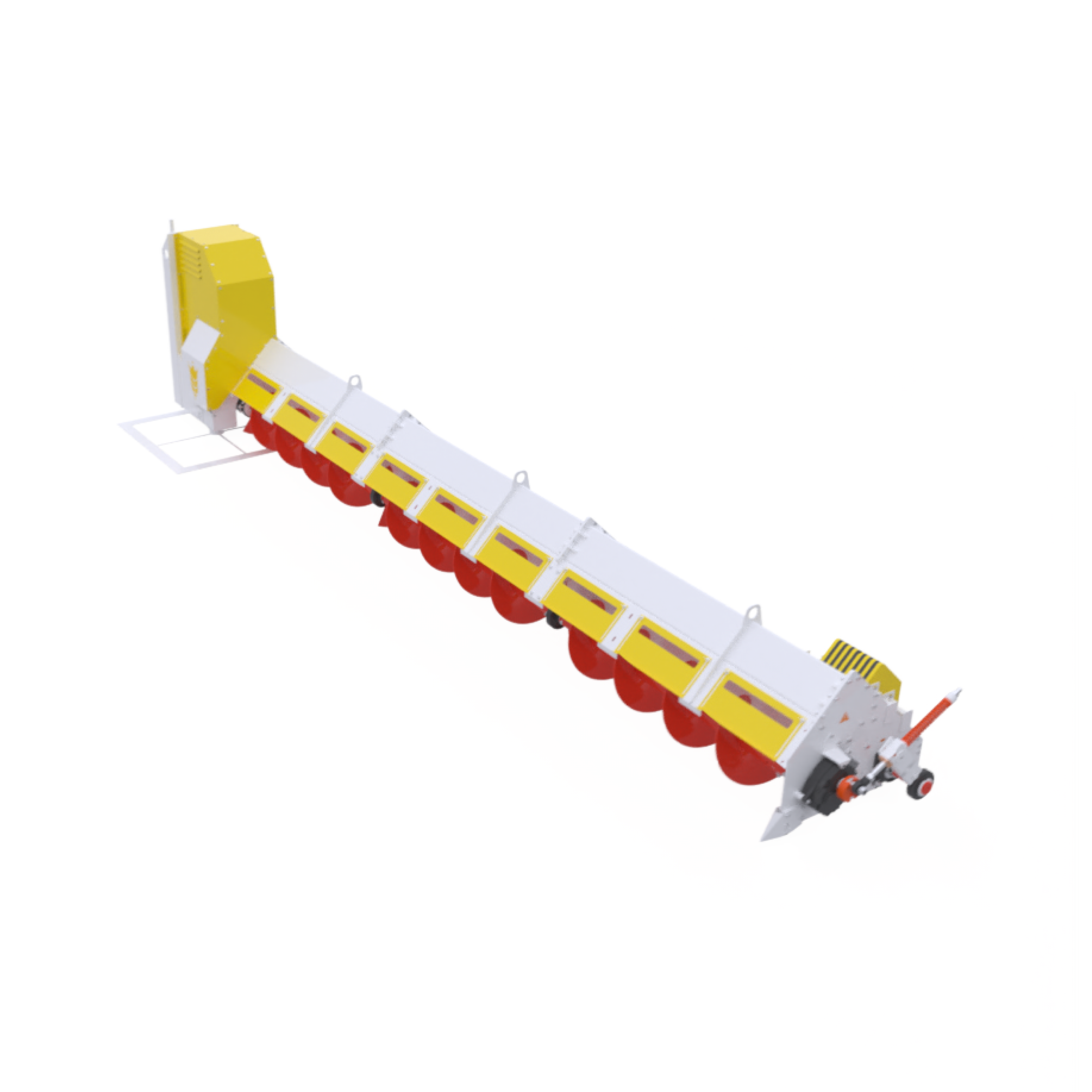

The sweep auger conveyor is intended for cleaning grain residues after unloading silos on a concrete (flat) base with a diameter of 16 to 32 meters. This system consists of a sweep auger located in a box and driven by an electric engine through a gearbox. On the drive side, the conveyor is pivoted to the axis of the central discharge hopper of the silo. This causes the conveyor to make circular movements around the geometric axis of the silo using the "tractor" pushing mechanism.

The cleaning scraper conveyor is used to clean grain residues after unloading silos with a concrete (flat) base with a diameter of 16 to 32 meters.

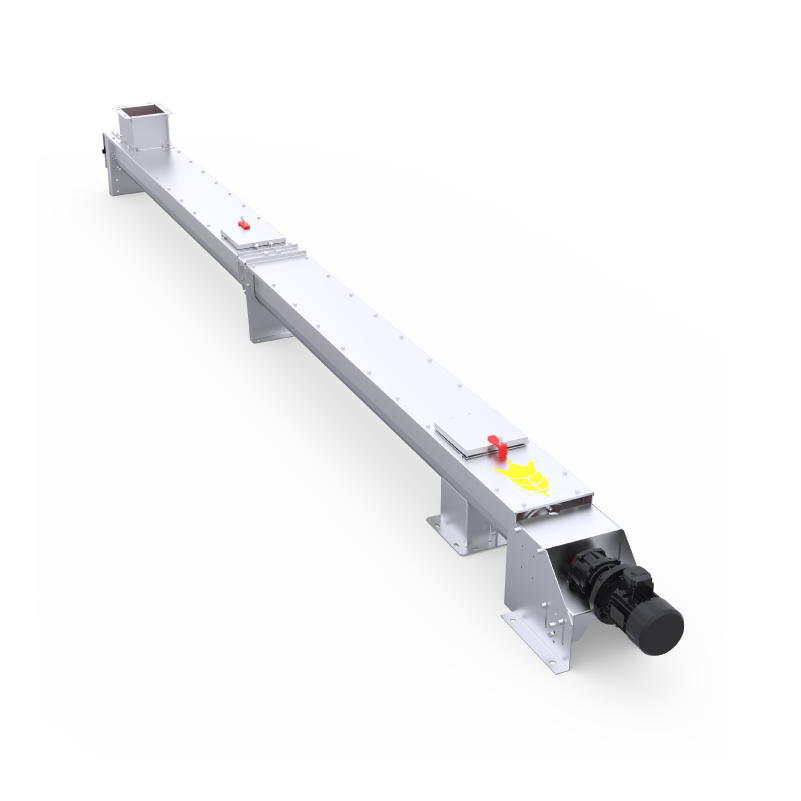

Screw Conveyors

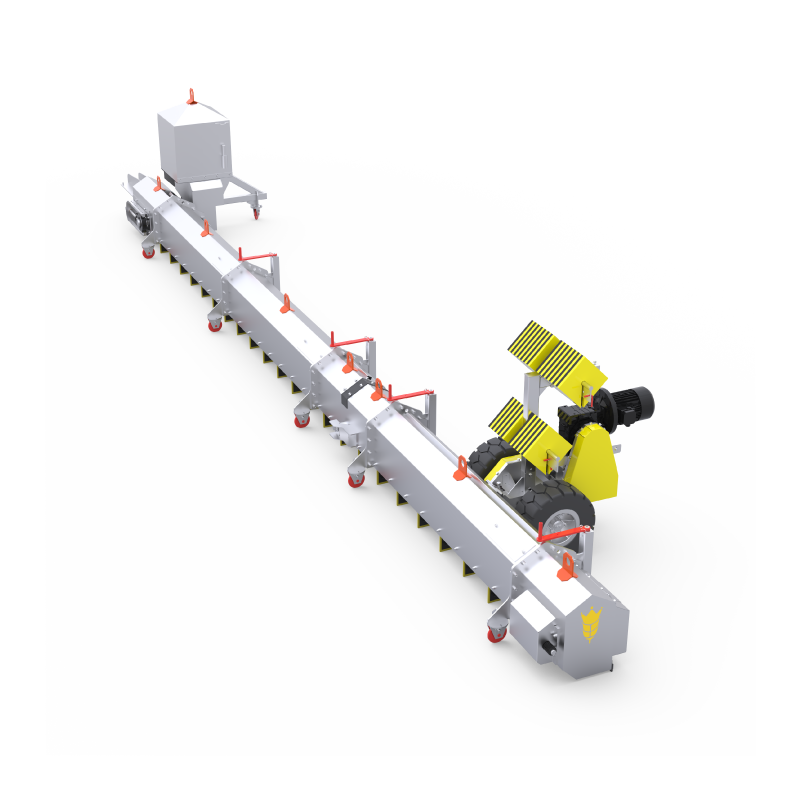

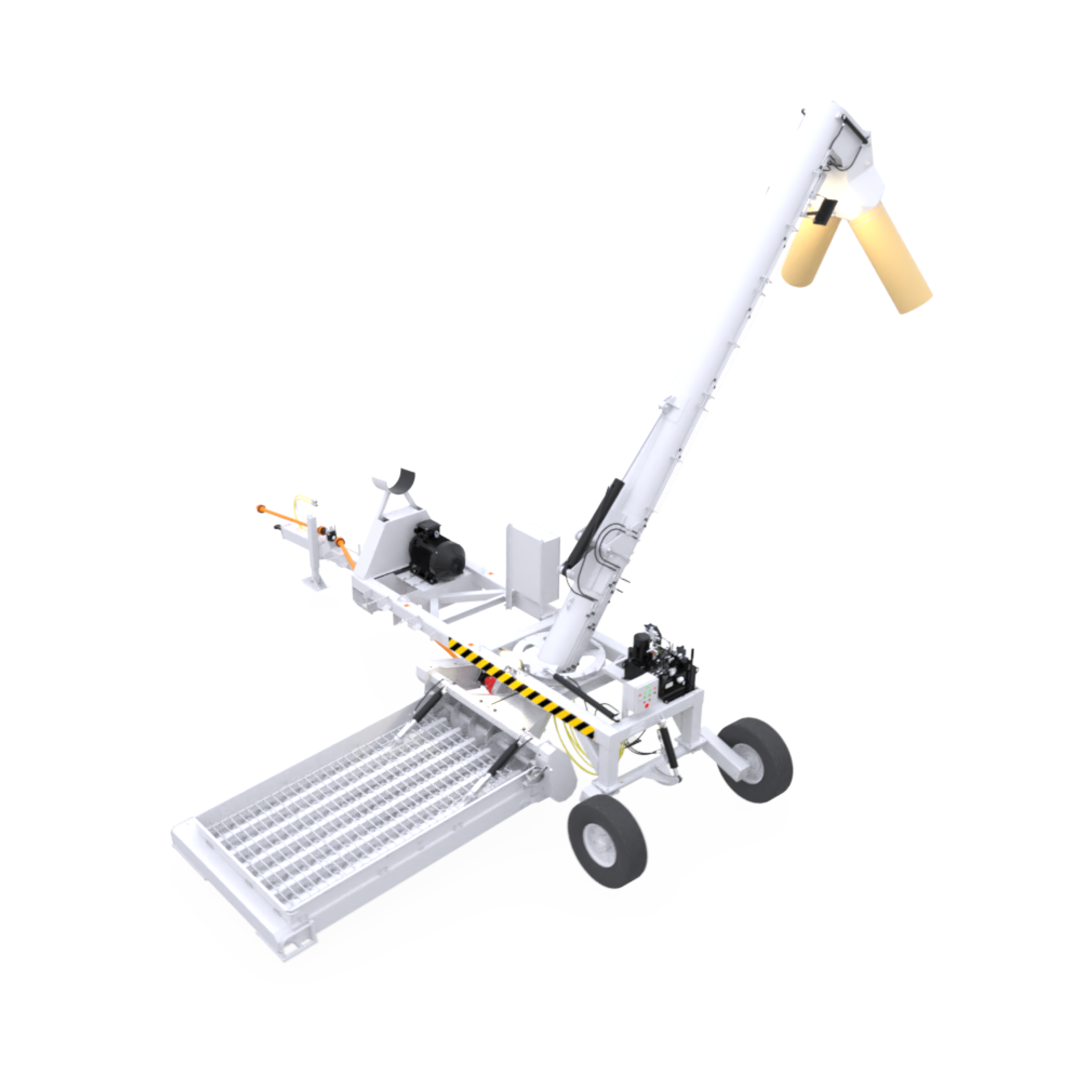

Mobile Screw Conveyors

ZEO-DSC is made up of 8 horizontal augers, 1 assembled auger, and 1 unfolding vertical auger, which are assembled on a frame with a running system. It is built on a frame with a wheeled chassis and equipped with a trailer hitch and lighting system, which allows transportation within the work site by tractor.

The grain is fed from the hopper wagon into the receiving tray of the ZEO-DSC machine. Then it is conveyed by two receiving augers to the intermediate chamber, where the main unloading auger is installed, which moves the grain further along the technological line.

The product is fed into the receiving hopper and then transported by a screw conveyor to the technological line or vehicle. It is built on a frame with a wheeled chassis. This system is equipped with a trailer hitch which allows transportation within the work site by a tractor.

Questions you may have?