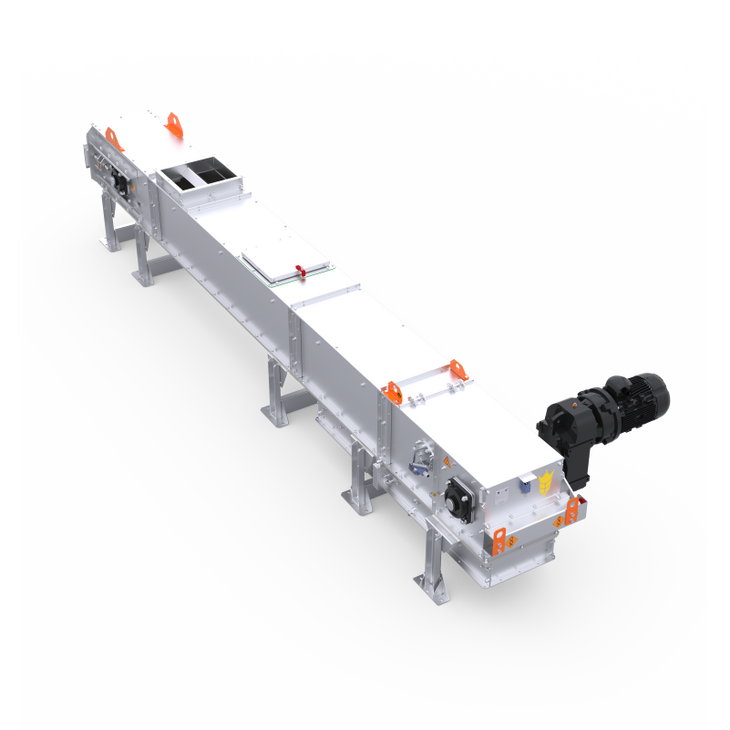

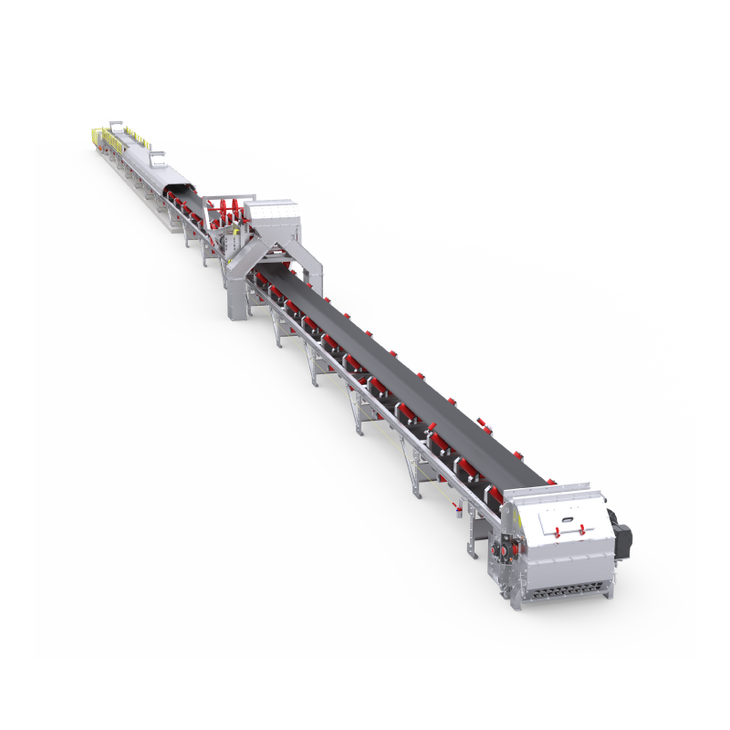

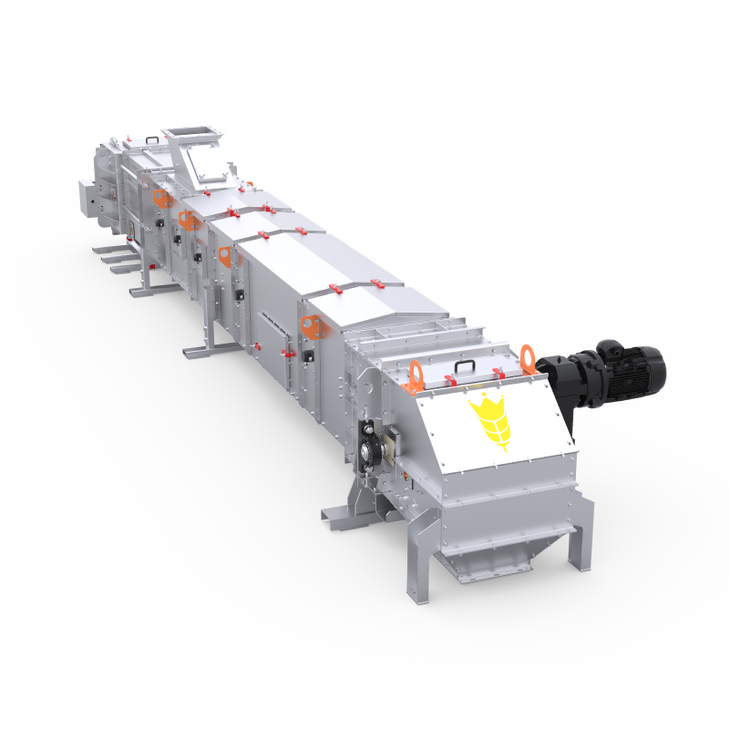

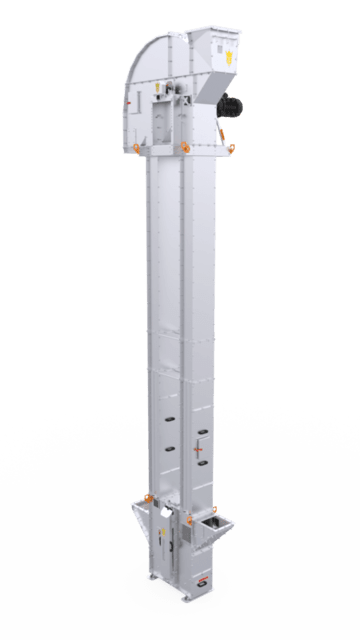

The bucket belt elevator comprises a continuously operating conveying device with a working unit in the form of a belt with buckets attached thereto. It is used to transport bulk cargo in a vertical direction. Gentle handling and minimal damage are ensured when moving grain. The bulk material is conveyed into the feed shoe, scooped up by the buckets, and then lifted up the working shaft. The buckets are discharged centrifugally in the bucket elevator head. Thanks to its low power consumption, the bucket elevator represents a perfect solution for the vertical transportation of bulk products.

The ZEO-BE bucket elevator can be installed as part of an elevator tower or working tower, or it can be made in ZEO-BES self-supporting design.ZEO-BES self-supporting bucket elevators feature a thoroughly designed and reinforced structure capable of withstanding significant vertical loads and is sufficiently rigid to allow installation outside the elevator tower or working tower (requires release at height).

- The drive drum is lined with special rubber featuring a diamond-shaped tread.

- European-made rubber fabric conveyor belts based on EP gaskets with oil-resistant, antistatic, and flame-retardant properties of rubber covers.

- The use of conical clamping bushings manufactured in-house for keyless connection of the drum to the shaft, significantly facilitating drum repair and allowing for high torque transmission.

- Possibility of transporting products with temperatures up to 120 ⁰C.

- The use of European-made drives with a high service factor.

- Locking the belt reversal with high-quality overrunning clutches.

- Production of drum shafts from alloy steels of Steel 45 and Steel 40X grades, followed by heat treatment.

- The barrel-shaped design of the squirrel cage tension drum prevents product sticking and centers the belt.

- Shoe cleaning deflector.

- Availability of a pressure discharge valve.

- Inspection hatches both in the shoe and head.

- Self-supporting bucket elevator design.

- Safety sensors included in the standard configuration: belt speed control, diaphragm support switch.

- Possibility of full integration into the ACS of an existing grain processing enterprise.

- An option to design equipment for operating conditions in ATEX 21 and ATEX 22 zones.

| F-series | L-series | P-series |

Warranty, months | 12 | 18 | 24 |

Operation mode | Concentration at harvest time | Regularly throughout the year | Daily and continuously |

Gearbox | Europe (SIEMENS) | Europe (SIEMENS) | Europe (SIEMENS) |

Electric engine | Europe | Europe | Europe |

Bearing units | Europe (PTI) | Europe (PTI) | Europe (PTI) |

Belt | China (SRB) | China (SRB) | Europe (Artego) |

Buckets | Polymer | Polymer | Polymer |

Reverse valve | Available | Available | Available |

Device for preventing product spillage into a return run | Available | Available | Available |

Inspection hatches | Available | Available | Available |

Drive drum lining | Europe | Europe | Europe |

Perforation of the belt for buckets | Available | Available | Available |

Speed control sensor | Available | Available | Available |

Shoe support sensor | Available | Available | Available |

Deflector for cleaning | Available | Available | Available |

Pressure relief valve in the head | Available | Available | Available |

Housing material |

|

|

|

Inner lining of the shoe/head | - | Available | Available |