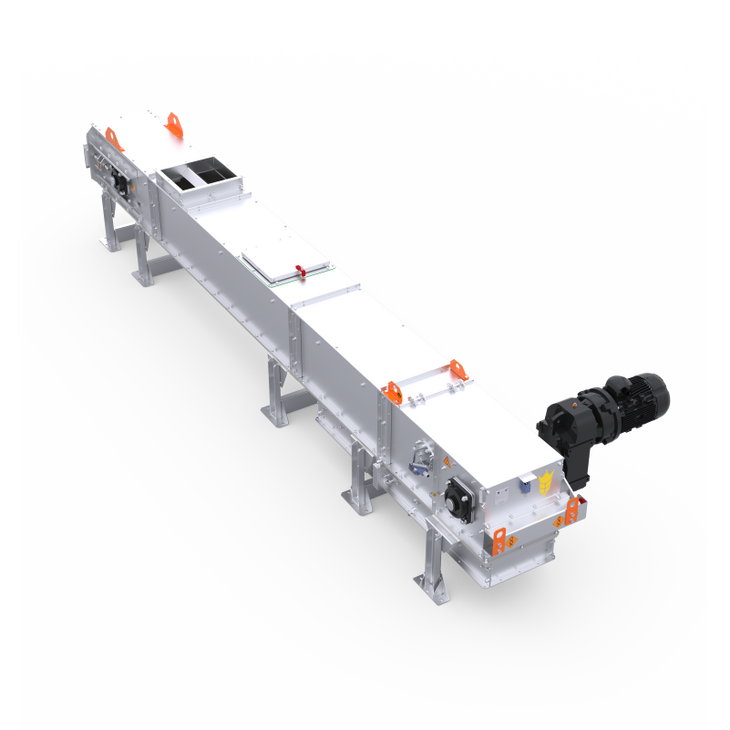

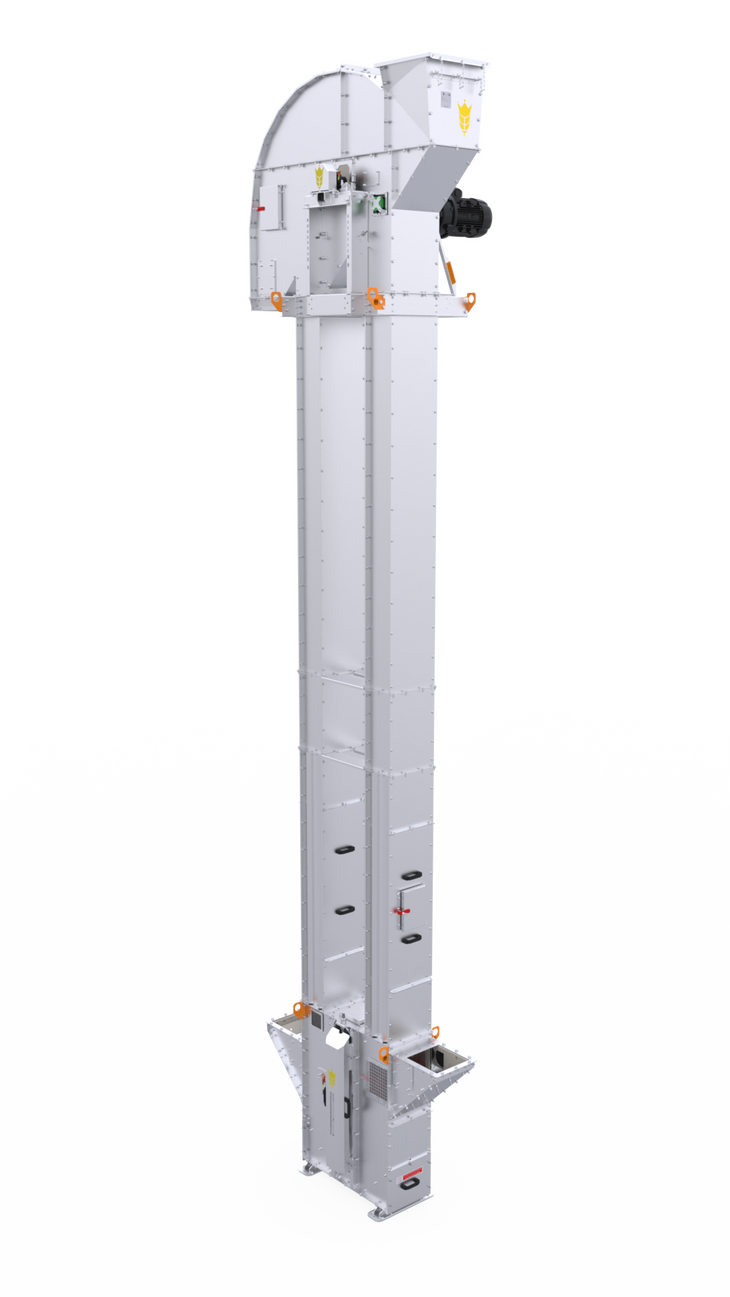

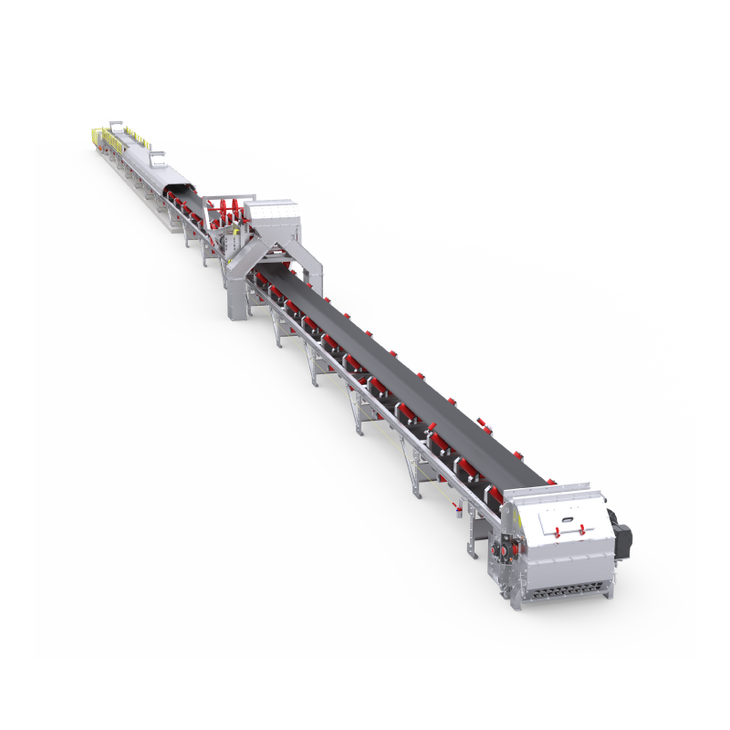

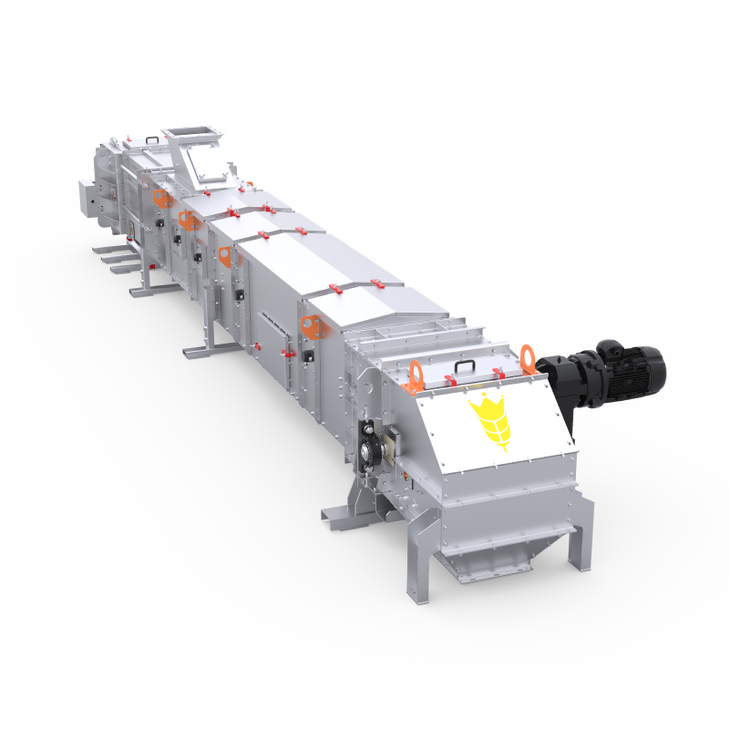

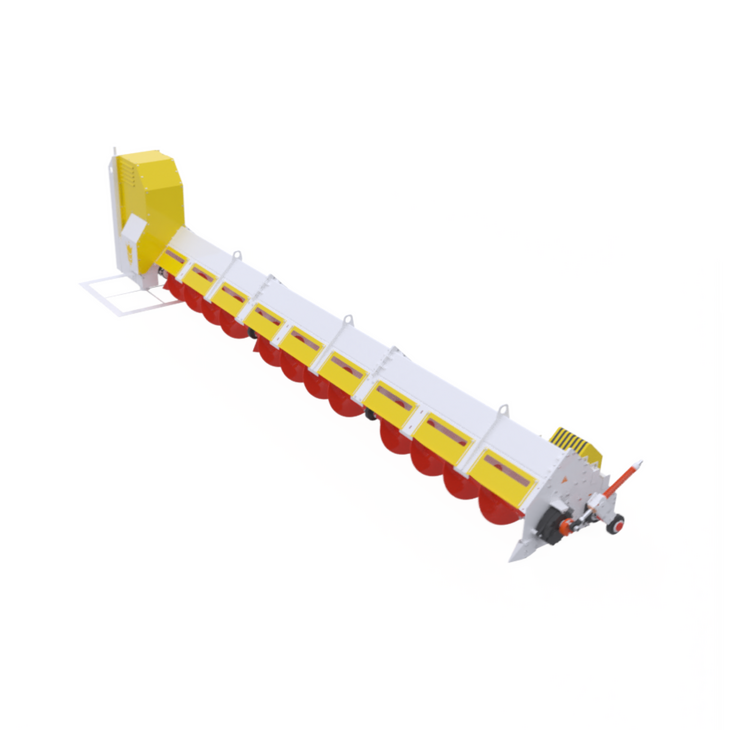

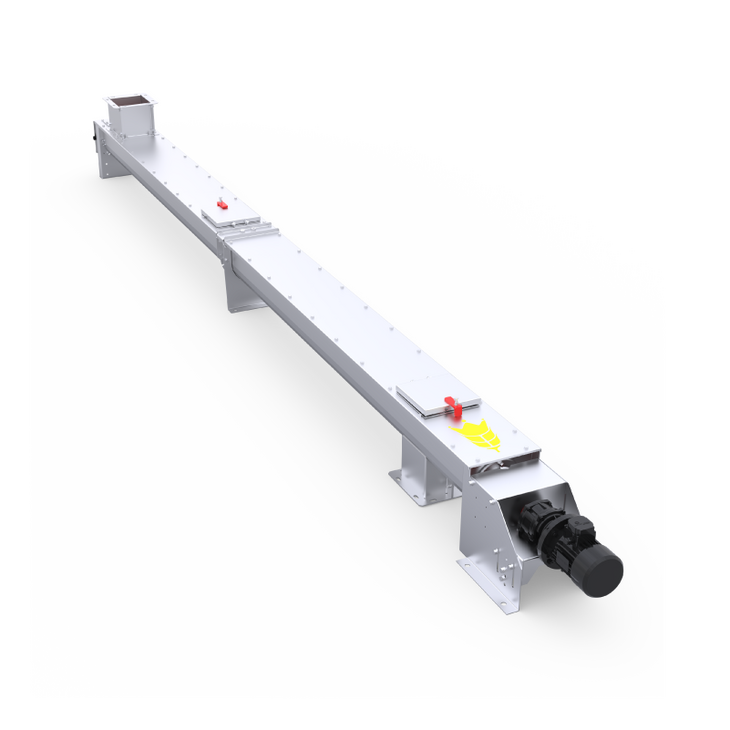

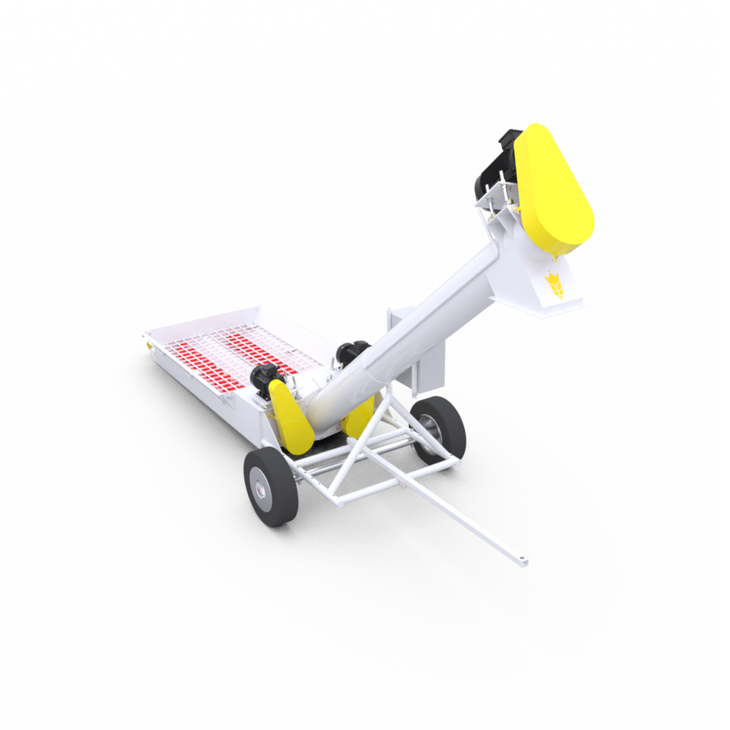

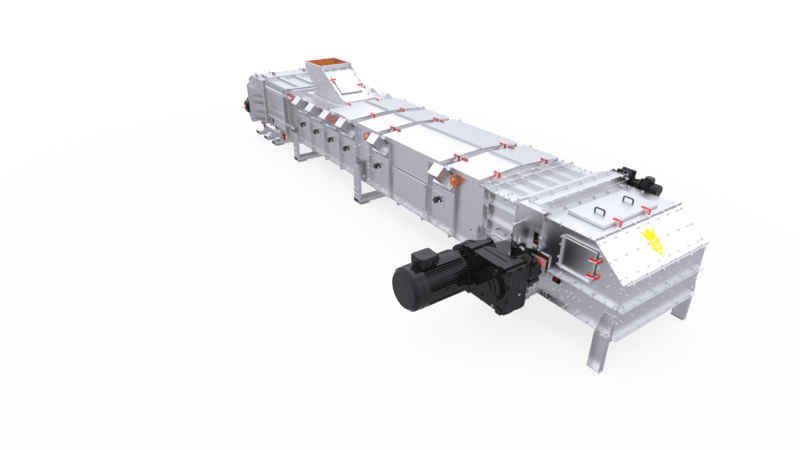

An enclosed belt conveyor is a continuously operating conveying device with a working unit in the form of a belt. It is used for transporting bulk cargo in horizontal, inclined (from -10° to + 22°), and horizontal-inclined positions. The enclosed belt conveyor is characterized by specially designed support rollers for the loaded strand, where the bearings are removed from the dust accumulation zone. The return run moves along the bottom lined with ultra-high molecular weight polyethylene PE-1000 (UHMW PE), possessing a low coefficient of friction and high wear resistance.

- It is operated outdoors and does not require closed spaces.

- When operating in closed or underground spaces, it does not emit dust outside the housing.

- An optimized design ensures simple and convenient operation.

- All bearing assemblies are kept out of the dust accumulation zone.

- The design of the duct and belt tensioner with a self-cleaning drum allows dust and spilled product to be returned to the loaded strand.

- The use of European-made rubber fabric conveyor belts based on EP gaskets with oil-resistant, antistatic, and flame-retardant properties of rubber covers.

- The use of conical clamping bushings manufactured in-house for keyless connection of the drum to the shaft, significantly facilitating drum repair and allowing for high torque transmission.

- Possibility of transporting products with temperatures up to 120 ⁰C.

- The use of European-made drives with a high service factor.

- Production of drum shafts from alloy steels of Steel 45 and Steel 40X grades, followed by heat treatment.

- Loading devices and discharge boxes are lined with polymers or wear-resistant steel.

- Safety sensors included in the standard configuration: belt run-off, belt speed control, and lanyard switch on both sides of the conveyor.

- Possibility of full integration into the ACS of an existing grain processing enterprise.

- An option to design equipment for operating conditions in ATEX 21 and ATEX 22 zones.

P-series | |

Warranty, months | 24 |

Operation mode | Daily and continuously |

Gearbox | Europe (SIEMENS) |

Electric engine | Europe |

Bearing unit of the drive and belt tensioner | Europe (PTI) |

Roller bearing housing | Europe (PTI) |

Rollers | Europe (ZEO) |

Conveyor belt | Europe (Artego) |

Drive drum lining | Europe |

Belt run-off switch | Available |

Speed control sensor | Available |

Emergency stop button (L<10 m) | Available |

Safety sensor with lanyard switch (L>10 m) | Available |

Housing material |

|

Discharge box lining | Polymer |