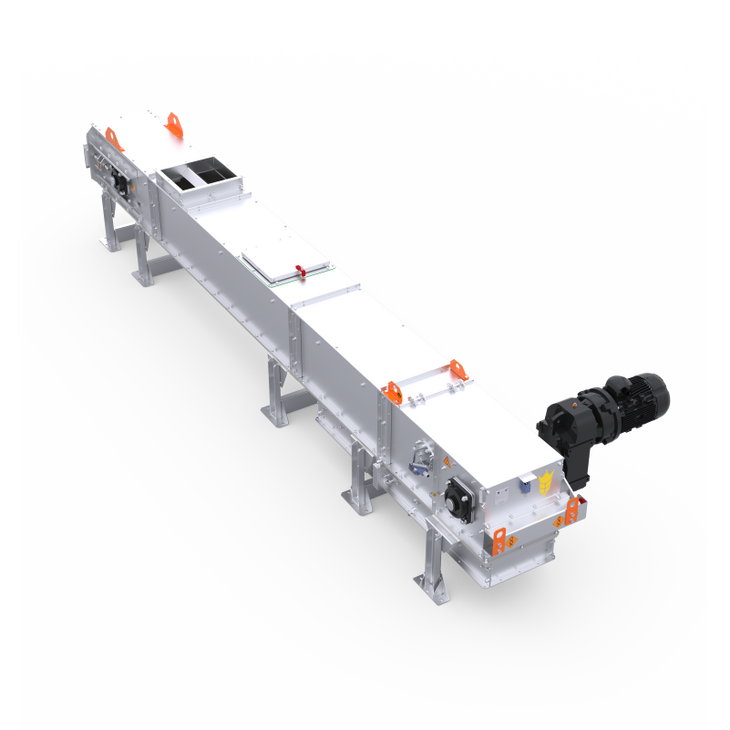

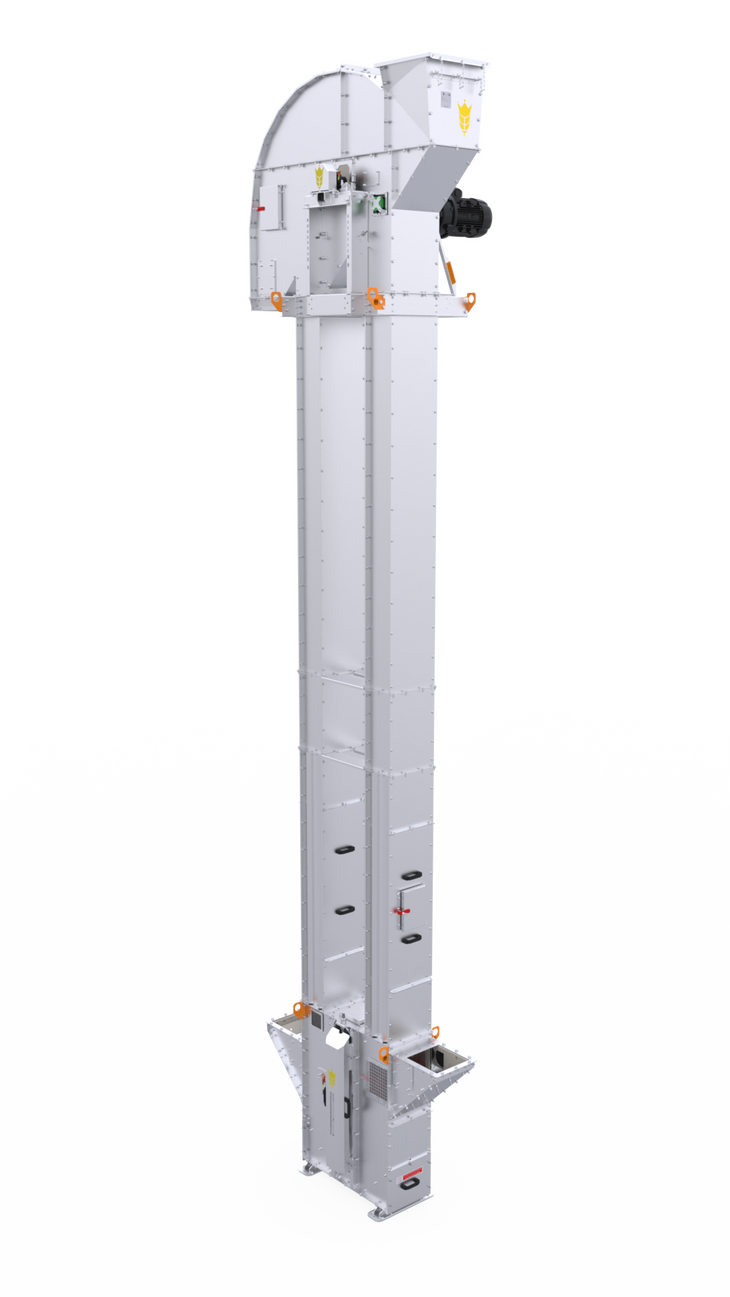

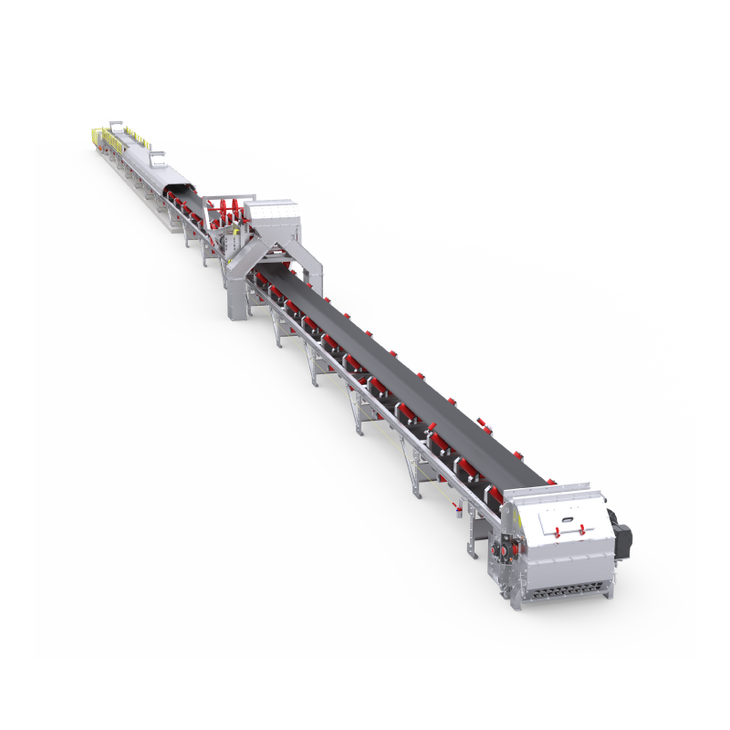

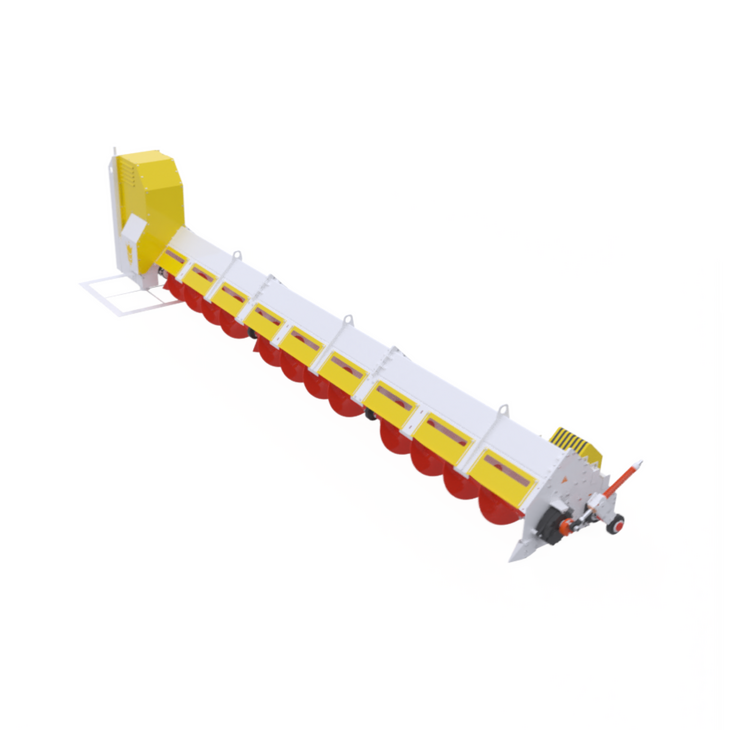

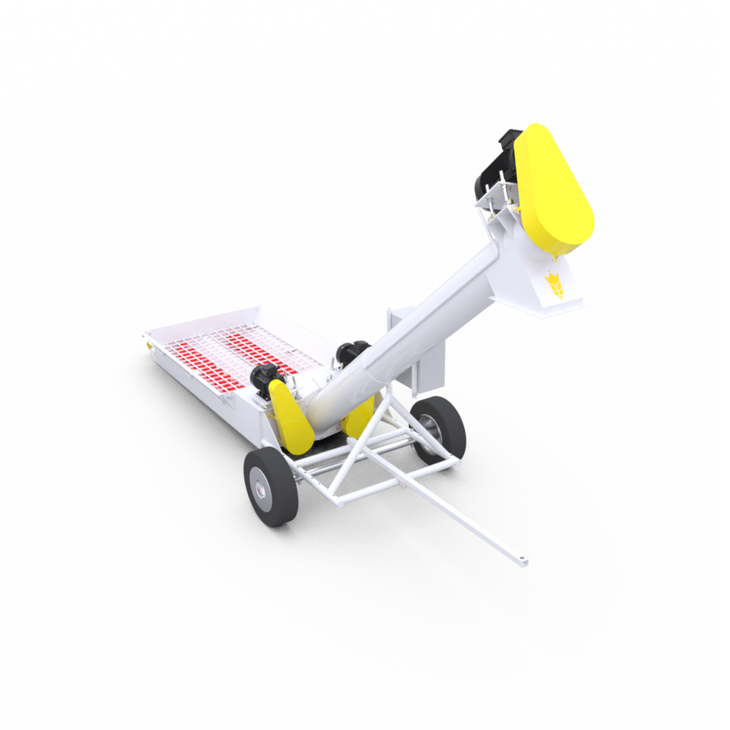

The ZEO-BC-RM mobile belt conveyor is a non-stationary(mobile) continuously operating device with a working body in the form of a belt. This transportation equipment provides gentle movement modes and minimal product damage when moving grain. The mobile belt conveyor is equipped with swivel wheels for moving around the territory of the enterprise and maneuvering in warehouses. It allows you to quickly build a temporary or stationary conveyor line.

Due to its versatile design, the ZEO-BC-RM mobile belt conveyor is effectively used in the agricultural sector, elevator facilities, port terminals and feed mills. High-quality support rollers used in the mechanism guarantee uniform belt movement and reduce wear. Additionally, elevator equipment can be equipped with automatic height and unloading direction control systems that optimize production flows.

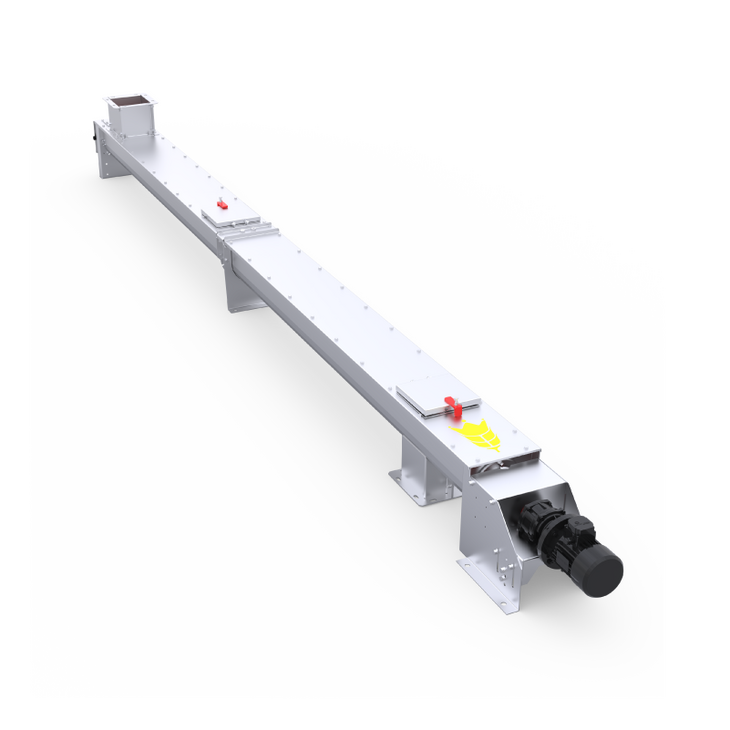

- Compact overall dimensions of the drive and tensioning station of the belt conveyor.

- The use of rollers made in Europe.

- Use of European-made rubber fabric conveyor belts based on EP gaskets with oil-resistant, antistatic and flame retardant properties.

- The use of conical clamping bushings of our own production for keyless connection of the drum with the shafts, which makes the drum repairable and allows for the transmission of high torques.

- Possibility of product transportation at temperatures up to 100 ⁰C.

- The use of European-made drives with a high service factor.

- Production of drum shafts from alloy steels Steel 45, Steel 40X with subsequent heat treatment.

- Shelter from atmospheric precipitation.

- Barrel-shaped geometry of the drive and tension drum to simplify belt centering.

- Safety sensors as standard on belt conveyors: belt runout, belt speed control, cable emergency switch on both sides of the conveyor.

- Possibility of full integration into the automated control system of an existing grain processing enterprise.

P-series | |

Operation mode | Daily and continuously |

Warranty, months | 12 |

Drive | Europe (Motovario) |

Bearing unit of the drive and belt tensioner | Europe (PTI) |

Rollers | Europe |

Conveyor belt | Europe |

Drive drum lining | Europe |

Belt run-off switch | Europe (ZEO) |

Speed control sensor | Europe |

Safety sensor with lanyard switch | Europe |

Discharge box | Available |

Discharge box lining | UHMW-PE1000 |

Housing material | Steel |

Coating | Polyurethane |

RAL | 7015 |

Control panel | Available |