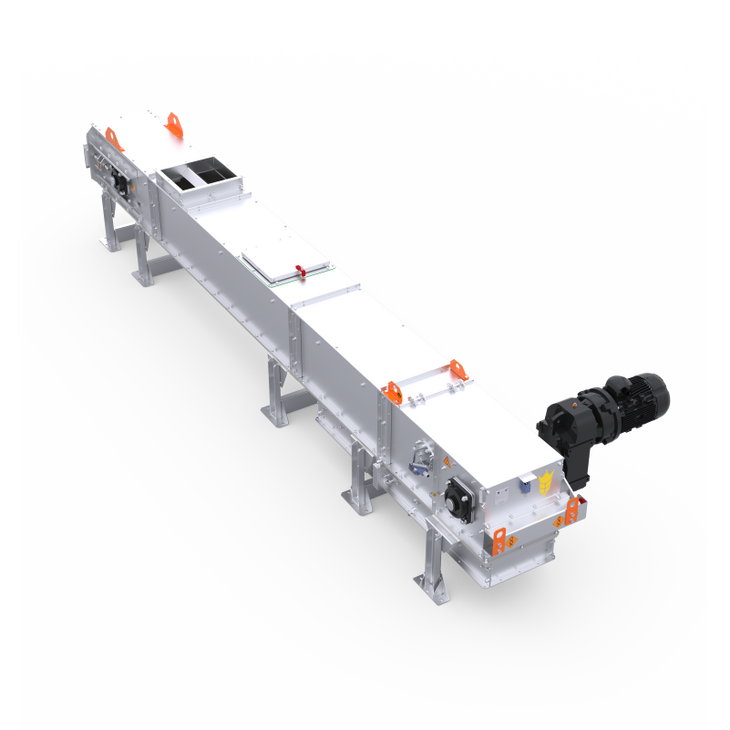

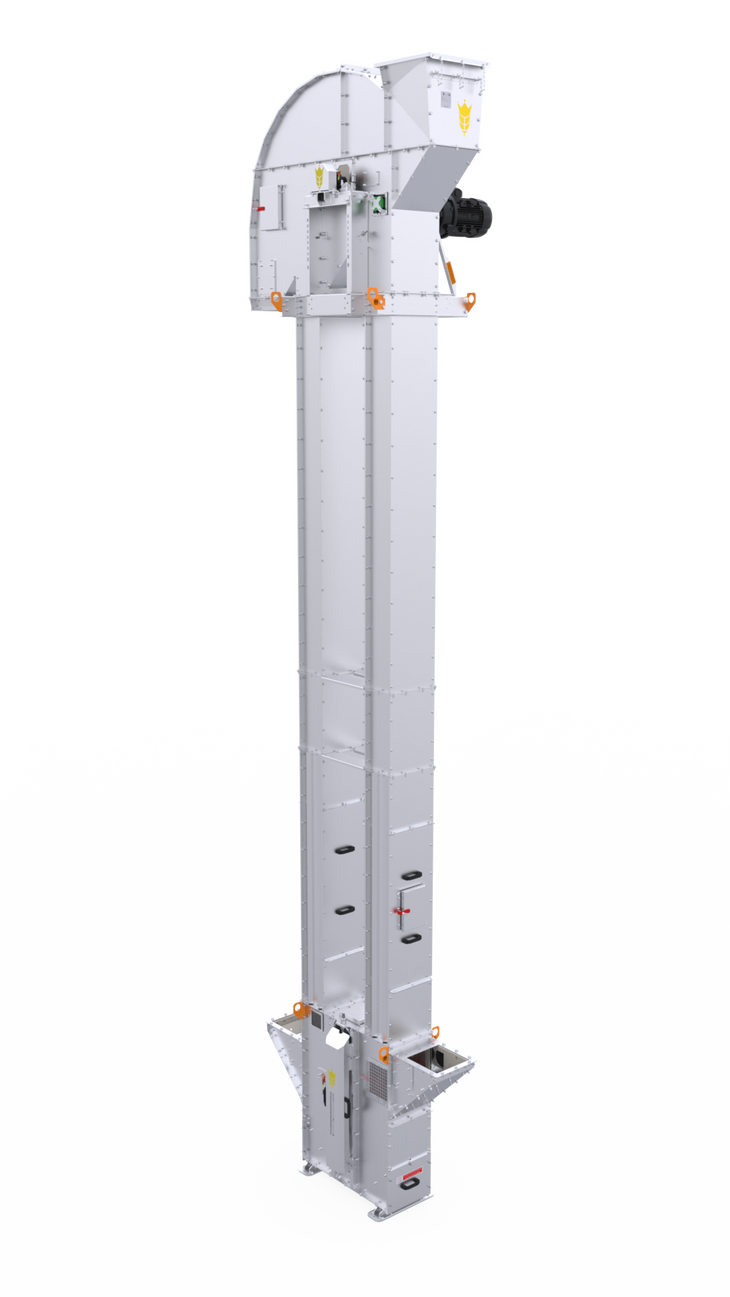

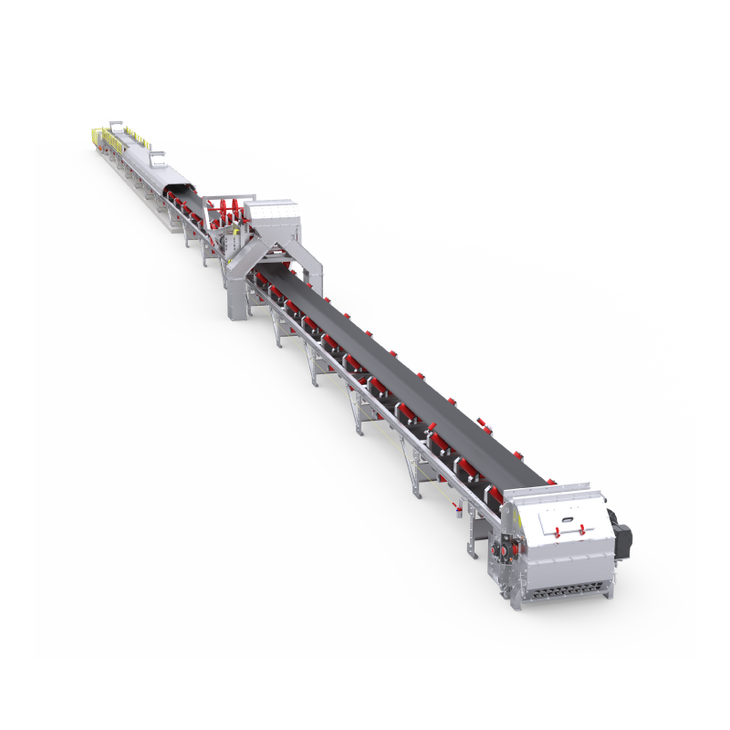

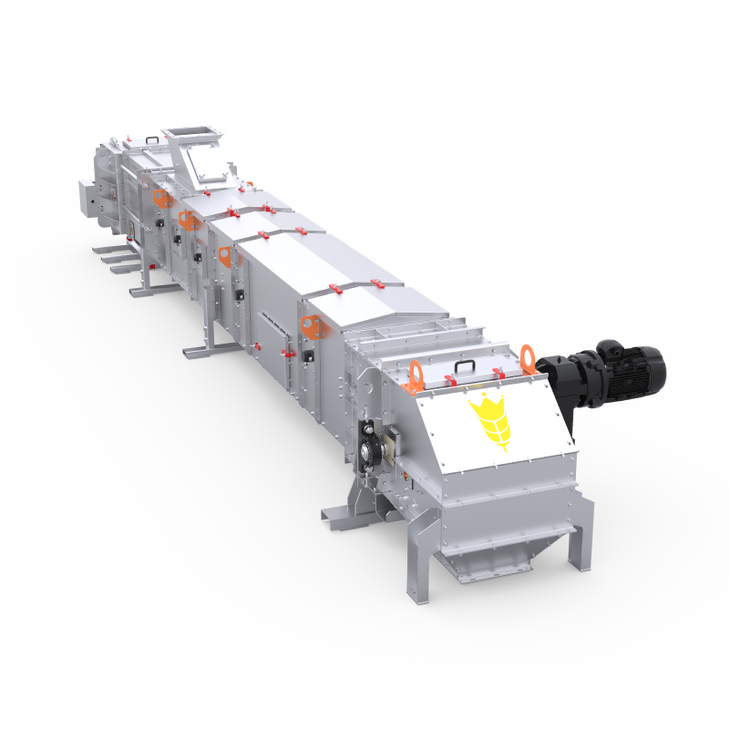

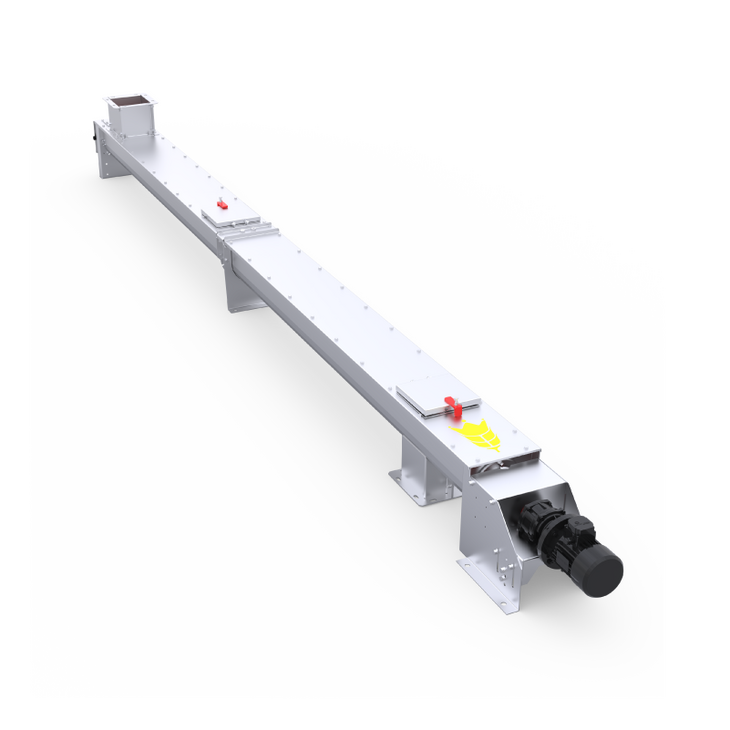

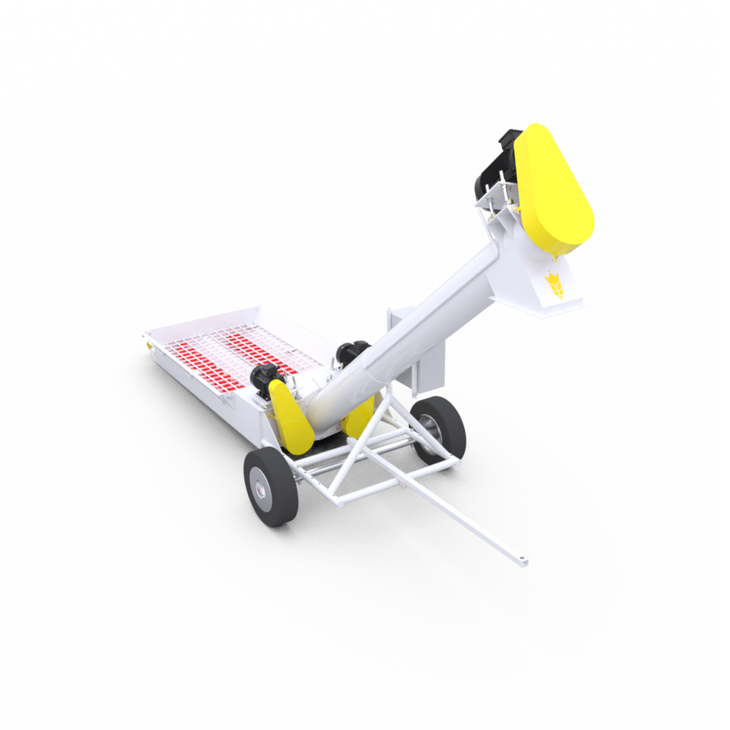

The ZEO-SA cleaning auger conveyor is designed for cleaning grain residues after unloading silos on a concrete (flat) base with a diameter of 16 to 32 meters. This elevator equipment operates as a screw conveyor consisting of a cleaning auger located in a box and driven by an electric motor through a gearbox. On the drive side, the conveyor is pivotally fixed on the axis of the central discharge hopper of the silo, which allows it to perform circular movements around the geometric axis of the silo using the pushing mechanism of the “tractor”.

In operation, the cleaning auger starts in semi-automatic mode to clean the remaining grain mass. The “tractor” brings the conveyor to the grain mass, and the screw conveyor moves the product to the central discharge hopper. When the load on the engine of the transport equipment increases above the set level, the electric motor of the “tractor” automatically shuts down and turns on after the load drops.

Detailed recommendations on setting up and operating the equipment can be found in the article: “ZEO-SA screw conveyor: a modern approach to transportation – operation, connection, control”.

- High degree of stripping screw conveyor reliability and maintainability.

- Replacement of the auger section without disassembling the conveyor body.

- Improved traction of the tractor with the silo bottom due to the design features of the “tractor”.

- V-belt transmission between the electric motor and the gearbox.

- Possibility of transportation, installation, repair and replacement in separate sections.

- Rigid bearing body.

- The design of the housing ensures maximum filling factor of the traction unit.

- Guaranteed passport performance.

- The minimum product residue after stripping is no more than 10 mm (depending on the flatness of the floor).

- Protection of the auger from blockage in case of breakage of the grain vault.

- Possibility of installing a drive station with an engine in the silo gallery.

F-series | L-series | |

Warranty, months | 12 | 18 |

Operation mode | Concentration at harvest time | Regularly throughout the year |

Auger drive | Europe | Europe |

Bearings | Europe (PTI) | Europe (PTI) |

Wedging protection | Available | Available |

Easy-to-access lubrication system | Available | Available |

Auger unit alignment | Available | Available |

Auger blade material | Steel 4 mm | Steel 6 mm |

Housing material |

|

|

Coating | Polyurethane | Polyurethane |

RAL | 7015 | 7015 |

Control panel | Available | Available |

Relevant power connector | Available | Available |