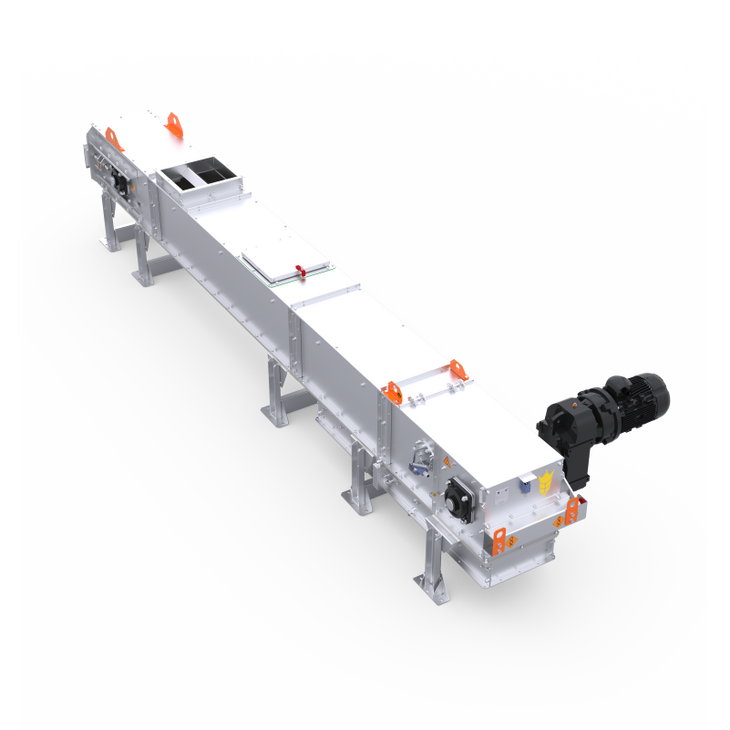

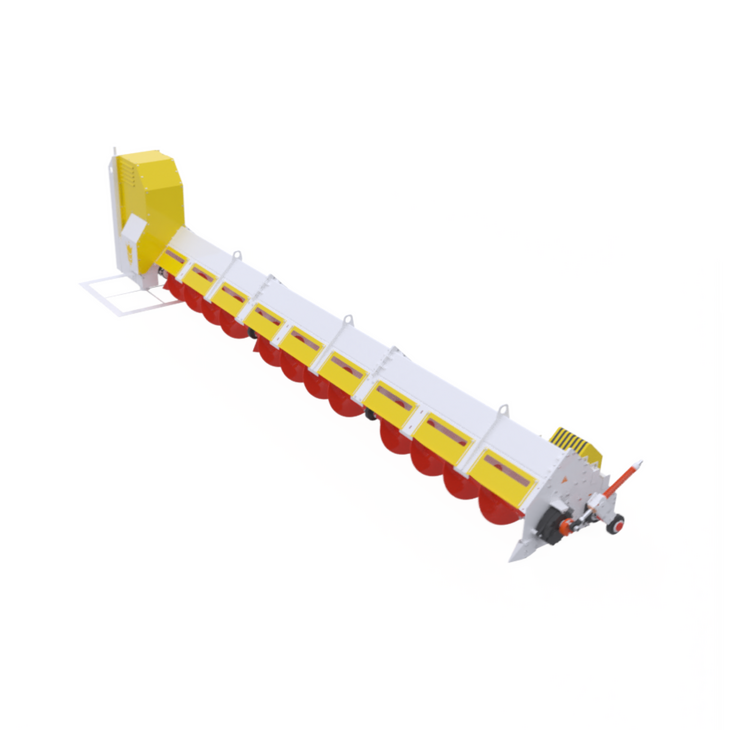

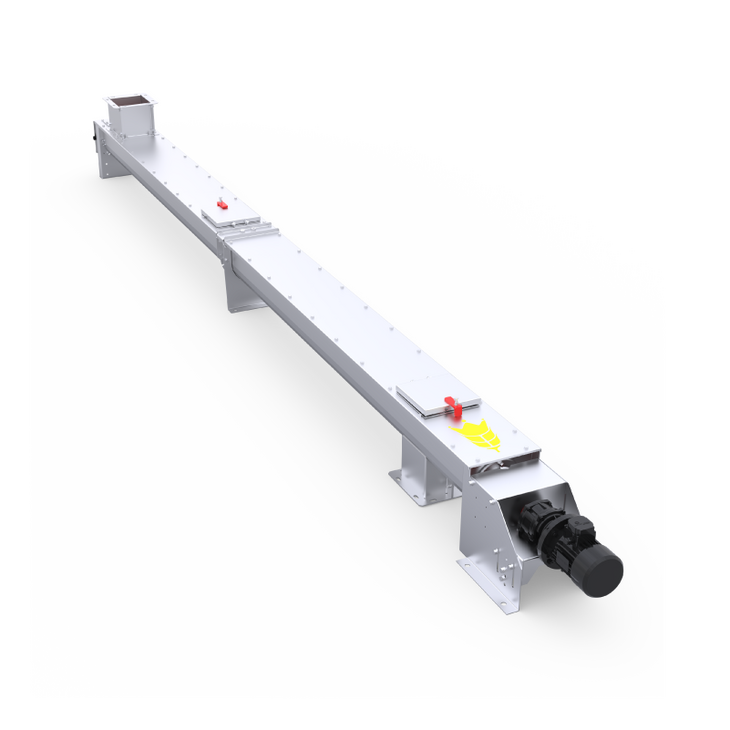

ZEO-DSC-60 Screw Wagon Unloader

Add to my project

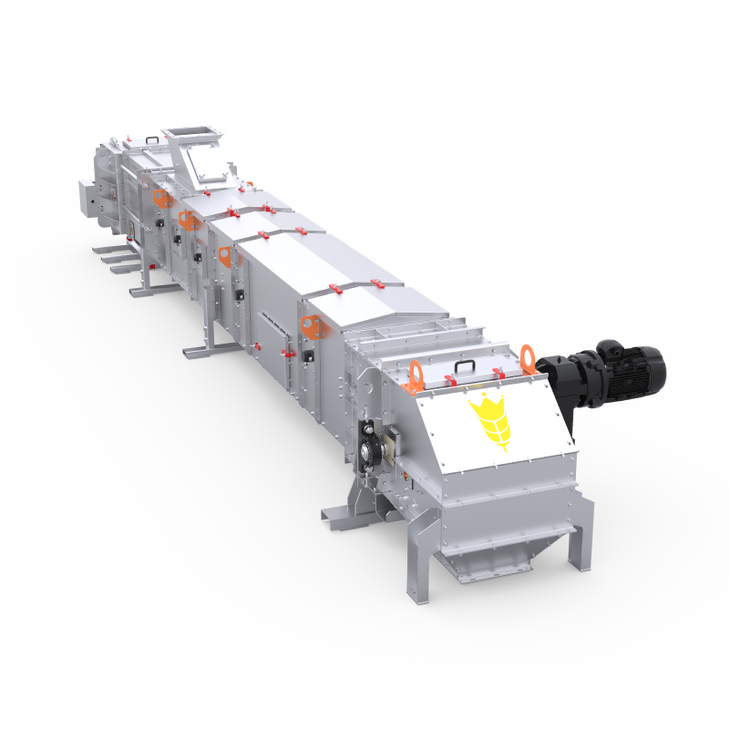

The grain is fed from the hopper wagon into the receiving tray of the ZEO-DSC machine. Then it is conveyed by two receiving augers to the intermediate chamber, where the main unloading auger is installed, which moves the grain further along the technological line. It is built on a frame with a single-axle wheeled chassis. It is driven by two manual operators: placing it under the wagon and, accordingly, repositioning it under the next unloading gate of the hopper wagon. The unloader is equipped with a control cabinet that drives three electric engines (one for each auger). The product lifting height is 2 meters. The unloader is compact and, if necessary, three unloaders can be installed simultaneously under the hopper wagon to increase productivity.

- Railroad wagons can be unloaded at any place convenient for vehicle access.

- Availability of a control cabinet.

- High standardization of the chassis.

- Lightweight and mobile construction.

- The equipment can be moved manually by two operators.

- Reinforced auger blade.

- An option to drain the accumulated water.

- Hinged sides (to reduce dust accumulation when unloading).

- Grease fittings on all bearing assemblies.