What does the future hold for elevators?

Economy, safety and simple control

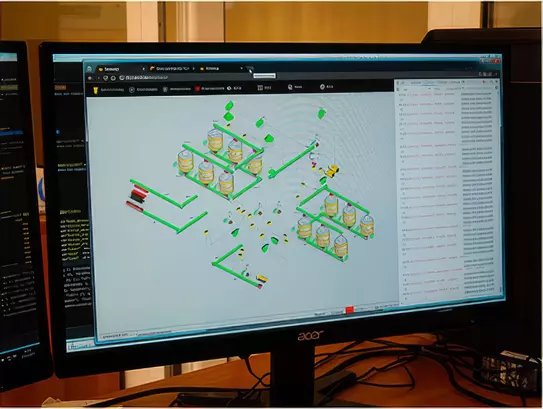

Modern automation systems, which are used at the majority of Ukrainian grain elevators, allow to control the technological process only by 30-40%. Many processes are still regulated manually and depend on the qualification of the operating personnel. Until recently, no one has tried to combine all these processes into a single automated system. Grain Capital specialists have set themselves such a goal by developing an innovative product "SMART elevator". Its main goal is full automation of technological, economic and other processes at the elevator on the basis of the fourth level of automation, which includes processing of large amounts of data and decision-making by the automated system with minimal human intervention.

SMART elevator system: four levels of automation

- Quality management control of the transport and technological lines (TTL): the system transmits information on the technical condition of the TTL and warns of the need for intervention by maintenance personnel.

- Optimization of energy consumption: the system adjusts equipment operation in modes that ensure maximum efficiency with minimum energy consumption.

- Monitoring the technical condition of critical equipment components: the system eliminates the influence of the human factor on the technical condition assessment.

- Maintenance scheduling: the system creates maintenance requirements and schedules.

Intelligent equipment: SMART Individual

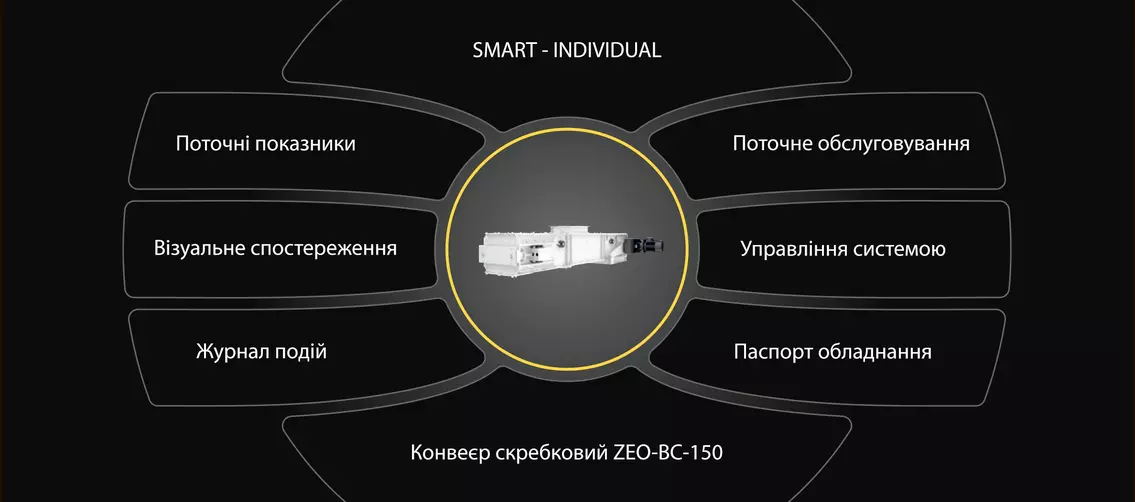

Every "smart" system is made up of individual units. "SMART elevator is no exception. This hardware and software complex is built on a modular principle, and its modules can function both separately - "SMART-individual", and as part of a single system - "SMART elevator".

One of the first developed modules is "SMART-aspiration". The system independently determines the required operation mode of the filtration unit network, taking into account the type of crop, productivity of grain streams, characteristics of dust extraction sources, dust concentration at the inlet, contamination of filter bags and so on. All data on the operation of aspiration equipment can be viewed from a smartphone or tablet.

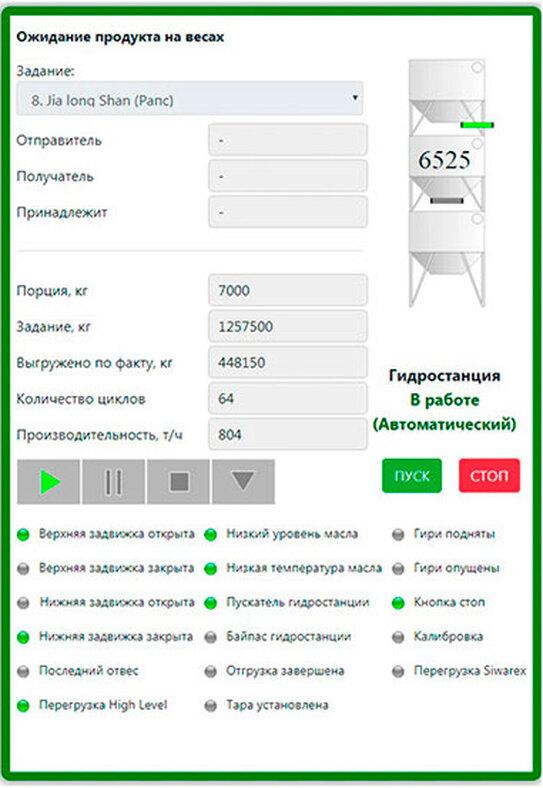

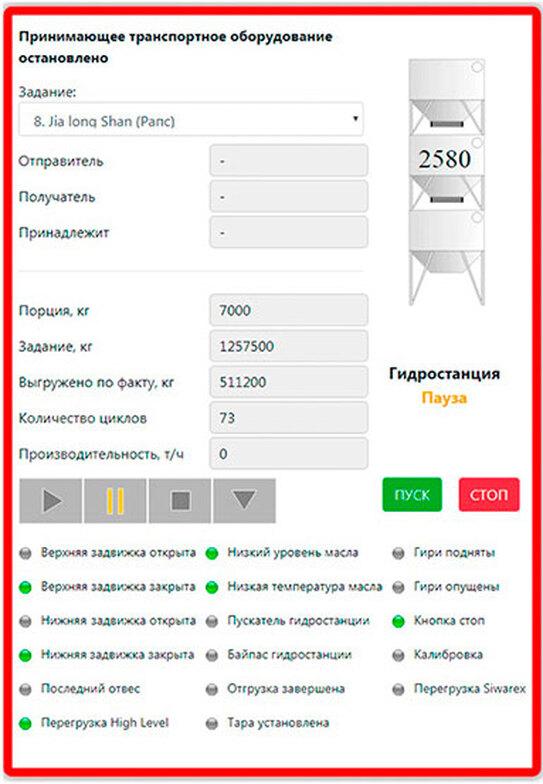

Today, transporters produced by Grain Capital Group of Companies have also become "smart". They are equipped with controllers with built-in Wi-Fi and a clear web interface that shows all the parameters of the equipment, from the technical certificate to the technical condition of the transporter.

Equipment reliability management

As you know, accidents are cheaper to prevent than to eliminate. "Smart equipment, both individually and as a single system, prevents any emergencies at the elevator. Thanks to the proprietary development of intelligent temperature and vibration sensors, the new system provides early warning of deviations from operating parameters, preventing accidents, fires and explosions.

Safety management

Safety management can be roughly divided into several parts - environmental, economic and cyber security. At Grain Capital, all automation systems were initially developed to eliminate air pollution, prevent fires and explosions. The SECURE-ELEVATOR GC system was developed to ensure cyber security.

Grain quality management in Ukraine

Grain Capital specialists have developed software that helps to forecast grain quality at the output of an elevator or grain terminal. This allows you to effectively manage grain quality parameters (moisture, clogging, etc.) and maximize profits at minimal cost.

Ease of maintenance

Despite the fact that the SMART Elevator system allows you to perform complex tasks, it is simple and easy to operate, which is important for the user. In conditions of shortage of qualified personnel, this is a big plus for large companies.

Today, Grain Capital's elevator automation system is being implemented at several Ukrainian companies that seek to improve the efficiency of production processes at their grain storage facilities.

Author of the article: Igor Gaponiuk, Chief Development Officer at Grain Capital.