Modernization of the remote control system for the grain storage of PJSC “Ukrelevatorprom”

The terminal is part of the ADM agricultural holding. ADM Trading Ukraine is a subsidiary of the international agro-industrial corporation Archer Daniels Midland Company. The main activity of the company is the production of sunflower oil and trade in grain crops.

Scope of work:

- Software modernization, updating the terminal's automated process control system according to changes after the reconstruction of the auto-reception unit - 2018.

- Software modernization, updating the terminal's control system scheme according to changes after reconstruction - 2017.

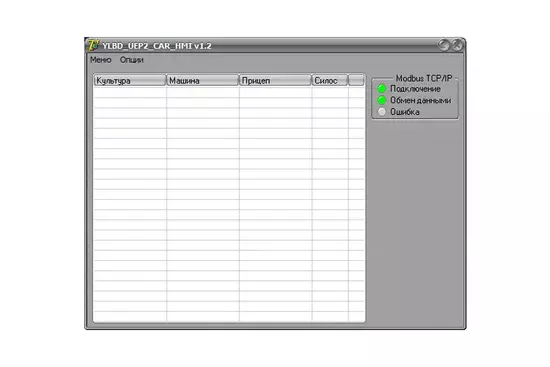

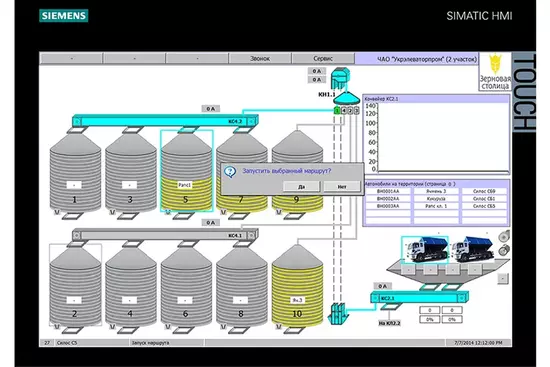

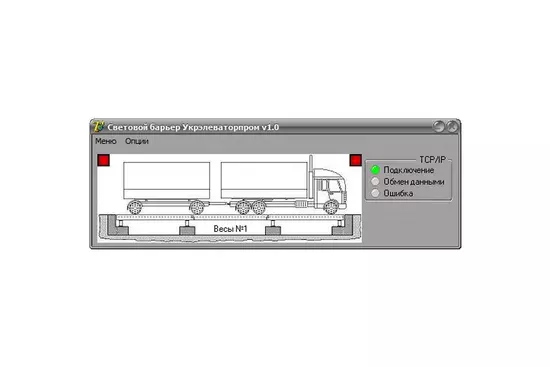

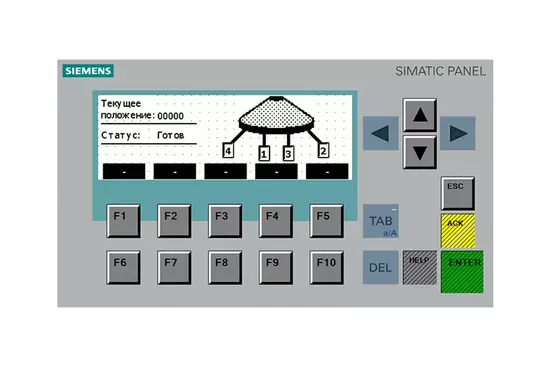

- Development of a SMART distributor - automatic position control and return to a given point; development of a SMART elevator - elevator equipment using clock timers and displaying them in the SCADA system; development of a program for automated control of the position of cars on scales during weighing to ensure the most accurate weighing - 2016.

- Design, manufacturing, installation and debugging of an additional automated workstation of the SDAU elevator - 2014.

- Reconstruction of SDAU terminal. Project development, manufacturing, installation, adjustment and commissioning of a new system for remote automatic control of the terminal - 2013-14.

More details about the reconstruction:

Customer's situation

PJSC "Ukrelevatorprom" is a transshipment complex in the port of Odessa with a one-time storage capacity of 210,000 tons, a leading enterprise in the structure of Alfred S. Toepfer International LLC (Ukraine).

The company has been operating since 2002. At the time of construction, it was equipped with an advanced and unique, at that time, control system of the company InnoVinnprom LLC.

One of the main criteria for business development Alfred S. Toepfer Ukraine is to increase the profitability and efficiency of production through the introduction of innovative management methods, which include the introduction of modern management systems and methods of conducting technological processes.

It became impossible to accomplish the task with the help of a morally and physically outdated system of remote automated control of the elevator. Therefore, the management of PJSC Ukrelevatorprom made a decision to reconstruct the remote automated control system by replacing automation equipment manufactured by InnoVinnprom LLC with equipment from Siemens and developing new application software based on the SCADA system WinCC interface, which would be similar to the application package developed by InnoVinnprom LLC.

A special condition for the reconstruction of the management system was that it was necessary to carry out this work practically without stopping production, using a period of time of several weeks, bound by a strict loading schedule for sea vessels, jointly approved by representatives of the grain trading company, Odessa MTP and the cargo carrier.

Selecting a work contractor

The heads of the technical departments of PJSC "Ukrelevatorprom", the chief engineer and the chief power engineer were instructed to request the submission of their proposals for the implementation of this project to a number of companies involved in the automation of technological processes. Proposals to implement this project came from several companies.

Criteria for the final selection of the work contractor

The final decision to select a contractor was based on the following:

- GC "Grain Capital" has specialists with more than 30 years of experience in the field of automation of grain processing enterprises;

- GC "Grain Capital" has positive experience in designing, manufacturing and implementing projects of this scale;

- GC "Grain Capital" has specialists who have in-depth knowledge of both the existing, prior to reconstruction, technical base of equipment of the company InnoVinnprom LLC, the technical base of equipment of the Siemens company

- GC "Grain Capital" has a powerful production base;

- GC "Grain Capital" is a developer of modern highly efficient technologies for managing elevator complexes;

- GC "Grain Capital" offered the best price-quality ratio and the shortest installation and commissioning time.

Pre-project preparation

At the beginning of the design, a number of joint working meetings were held between specialists from the design department of Ukrelevatorstroy LLC together with leading technical specialists from Ukrelevatorprom PJSC.

Based on the results of the meetings, the main problems that required solutions to optimize the progress of work were identified:

- Lack of final technical specifications.

- Discrepancy in standards and communication protocols for technical means of control systems.

- The choice of equipment on which the control system was supposed to be built did not meet the optimal price-quality criteria.

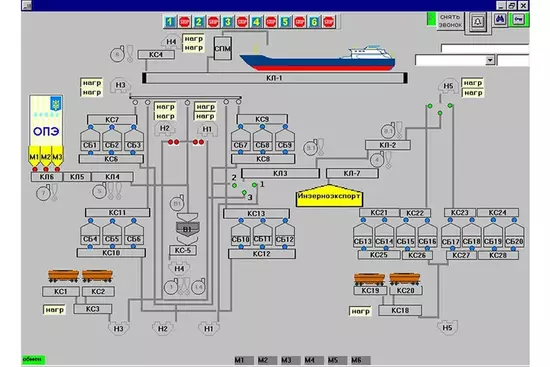

Stress-free transition from one control system to another in a short time. (Fig.1)

Based on these problems, together with specialists from the Grain Capital Group of Companies, it was decided:

- A technical specification for carrying out work to reconstruct the control system has been generated.

- Taking into account the specifics of production and fulfilling industry requirements, we will place all automation equipment in cabinets of the new “Spacial SF” design with a degree of protection IP55 manufactured by Schneider Electric (France).

- We determined the configuration of automation equipment divided into two independent sections with S7-317 PN/DP central processors with a structure of distributed peripheral devices based on ET200M modular stations, allowing the use of the entire range of signal and functional modules of the standard S7-300 programmable controller.

- Adopt the ProfiNet communication protocol standard, which allows data to be transferred at high speed, and increase the number of I/O modules served by standard IM 153 interface modules.

- Equip all automation and distributed peripherals cabinets with stabilized power supplies with uninterruptible power supplies and batteries that can maintain the supply voltage for up to 7 hours.

- Routers with an extended temperature range can be used as signal repeaters.

- List of control elements and functionality of SCADA system terminals.

- Ensure coordination of all work carried out within the framework of this project with all responsible persons interested in the operation of the reconstructed complex.

- Break the work package into stages.

Stages of work

- Formation of technical specifications.

- Design.

- Complete set of control and automation equipment.

- Manufacturing of control and automation panels.

- Installation of monitoring, control and automation equipment.

- Setting up control, management and automation tools.

- Comprehensive setup of a remote automated control system.

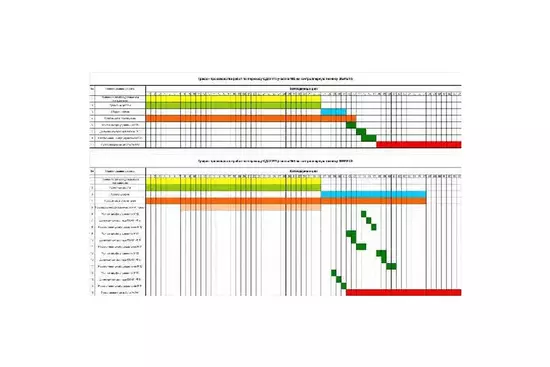

Work plan

Before starting the design, a complete list of works necessary to complete the task was determined.

As a result, a calendar schedule was generated, indicating the responsible persons and the deadlines for completing the work stages - You can see the general view of the calendar schedule in Fig. 2.

Formation of a working group.

After drawing up the schedule, a project working group was assembled. It included heads of structural divisions of Ukrelevatorprom CJSC and leading specialists of the automation department of the Grain Capital Group of Companies.

Project documentation

At the design stage, a permanent group was organized, consisting of specialists from PJSC Ukrelevatorprom, as well as technologists and specialists in dust removal systems from the Grain Capital Group.

The created group made it possible to present in a short time the best technical solution for the implementation of the task, satisfying the customer.

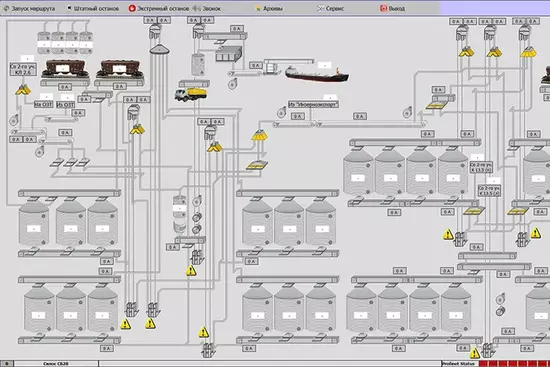

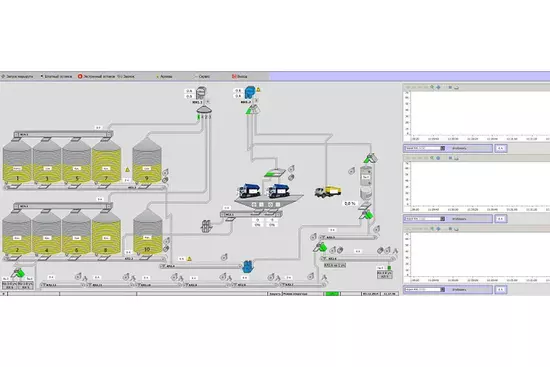

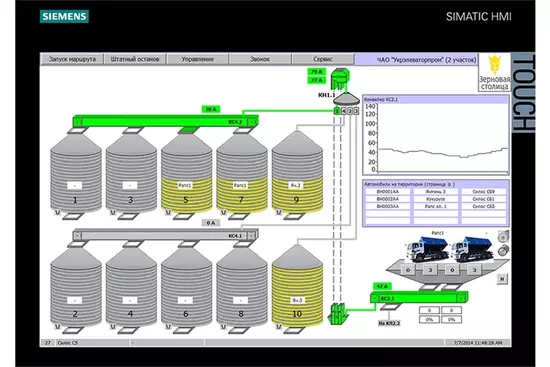

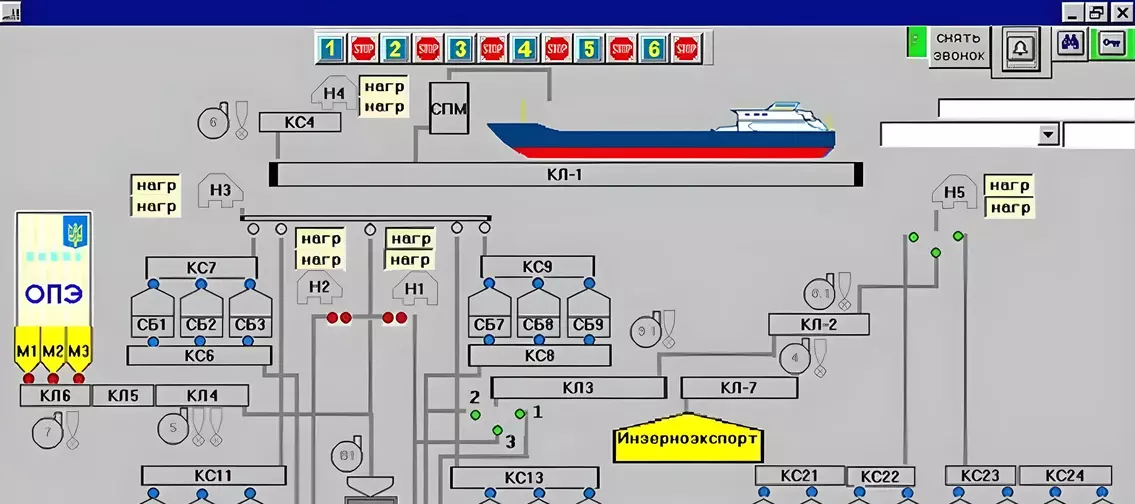

As a result, it was possible to develop a remote automated elevator control system (RAC), which allows:

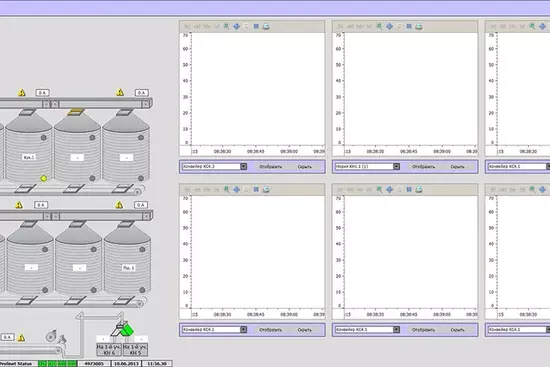

- carry out prompt collection and processing of data on the condition of all peripheral equipment: conveyors, elevators, mechanisms, sensors, bin scales, grain flow distributors, etc.;

- continuously diagnose accidents and deviations from the technological process with the issuance of alarms and information about the nature of the malfunction;

- take measures to prevent blocking of equipment and stopping routes;

- control motor load currents and shut them down to avoid emergency situations;

- control in automatic and manual, locked or debugging modes;

- control the availability of product in bunkers and silos;

- carry out weight accounting of goods;

- display technological parameters in different graphical forms;

- maintain production protocols.

Additionally, a mechanism was prepared for the shock-free transition of the control system of equipment from InnoVinnprom LLC to equipment from Siemens.

For this purpose, an OPC server was specially developed, allowing the SCADA system to simultaneously work with different controllers.

Technical means

- Special SF series control cabinets with degree of protection IP55 manufactured by Schneider Electric (France).

- Central processors: CPU S7-317 PN/DP.

- Power sources: SITOP SMART 240W.

- Uninterruptible power supplies: SITOP POWER DC-UPS.

- Batteries: SITOP POWER =24 V/7A TIME.

- Distributed peripheral system IM 153-4PN.

- ET200M I/O modules.

- Router: MicroTik RB 750.

PCs with a specialized SCADA system of our own design based on WinCC TIA Portal V12 are used as operator workstations.

Each workstation has two 24” monitors. With the help of one, the complex is controlled, with the help of the other, the current loads of all drives are monitored:

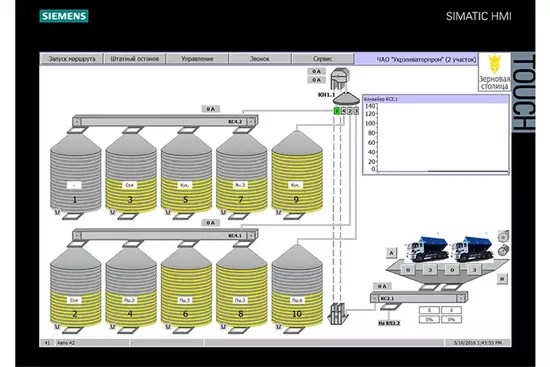

- Fig. 5 - Workstation of the operator of the first section.

- Fig. 6.-Workstation of the operator of the second section.

Result

As a result of the work carried out by the Grain Capital Group of Companies on the development, production and implementation of a remote automated control system for the elevator of PJSC Ukrelevatorprom:

- Reduction of implementation time in relation to similar systems due to the development and application of a shockless transition algorithm by 5 times.

- Reducing construction financing by reducing implementation time and reducing the cost of automation equipment by up to 15%.

- Reducing training time for SDAU operators due to the versatility of the interface used to 4-7 days.

- Reducing energy consumption for moving a unit of product due to algorithmic optimization of grain transportation routes from 10% to 12%.

- Reducing maintenance costs through the use of highly reliable equipment produced by a leading electrical engineering company and the latest application software developed by Ukrelevatorstroy LLC with patented PointStart and SoftRoute functions by up to 17%.

- A new control system was built based on equipment whose manufacturer can provide maximum technical support with minimal delivery times for spare parts.

- It became possible to further expand the control system and support it with the help of maintenance personnel or in the case of after-sales service.

Customer comment

Cooperation period:

2013-18