Do you need to automate your agribusiness?

Have you ever thought about the competitiveness of your business? Probably yes, and more than once. Modern life does not stand still, it is constantly evolving, and to survive in this world, all decisions regarding HR management and organization of business processes must be oriented to the level of existing competition in the industry. The question arises: how to meet such a large number of requirements? To do so, you need reliable allies to rely on when critical situations arise.

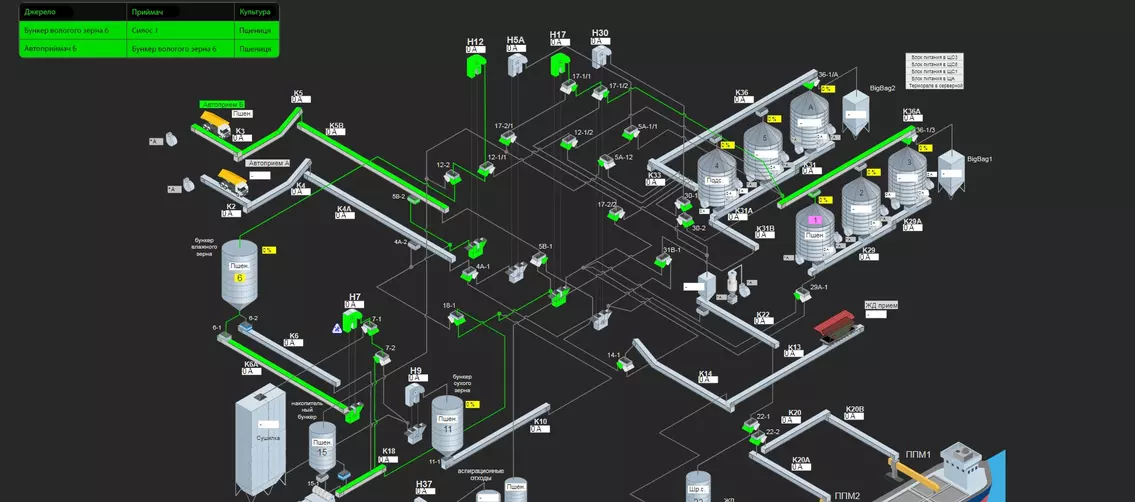

The integrated platform developed by Grain Capital, which is able to unite all the production management systems of a company, will be an excellent ally in the competitive struggle.

Grain Capital offers two hardware and software products that can fully automate grain elevator operations:

- SMART-DAU

- SMART-Individual

Modern elevator automation helps you to manage your entire process efficiently.

What tasks does the SMART system solve?

Grain Capital's software development allows you to:

- monitor product quantity, quality, and condition;

- manage routes and perform automatic calculation of energy consumption;

- monitor and send information about malfunctions of units and equipment;

- perform intelligent weighing;

- control the temperature of grain in silos;

- work with accounting programs.

Unlike other software solutions on the market, Grain Capital's program is easy to manage and has unique control algorithms, thanks to which you will be able to build your production process in such a way that you will soon achieve the most efficient results.

How to choose a program for elevator automation?

Each developer has its own vision of elevator operation and accordingly offers its own approach to automate the work processes of the elevator. As a rule, the basis of such software products is the outdated WinCC technology. This program is a standard dispatch automated control system (DACS) to which only the on-site operator has access. It consists of a number of different accounting programs and programs for traffic flow analysis, etc. The problem with such solutions is that all these programs work separately and it is almost impossible to integrate them. As a result, to see the real activity of the grain elevator, you have to inspect it yourself or have someone prepare a report. Without knowing the real situation at the enterprise, you will not be able to make timely decisions, which can lead to loss of competitive advantages.

The SMART-elevator program uses the latest technologies of interaction between the management staff and branches. This module integrates all existing information flows. Implementing our system in your grain elevator will give you access to a variety of data from anywhere. You can get information at any time, e.g. silo fullness, loading and unloading, active routes, etc.

What advantages does the SMART elevator automation program have?

Thanks to this program you will be able to control all the work of the elevator online and receive reports at any time. There is no need to buy expensive licenses for SMART-DAU software. Another advantage is the use of MySQL database, which provides easy connection of SMART-SDAU to various systems, for example, accounting programs.

Setting up the equipment does not require stopping it - if the Internet is available, the entire elevator can be restored within 15 minutes. ACS (automated process control system) will protect the elevator from hacker attacks and unauthorized access of unauthorized persons.

What are the features of the SMART-Individual automation system?

This module allows you not only to control the elevator equipment, but also to monitor its operation even from a tablet. This smart equipment will prevent unscheduled shutdowns, accidents, explosions, fires and so on. The number of employees is minimized, and the module does not require expensive licensing and complex implementation. The cost of the module is affordable, so it can be afforded by both large agricultural holdings and mini-elevators.

The product is equipped with built-in temperature sensors that prevent fires and explosions in the units and mechanisms of the operating equipment. There is also a vibration sensor that monitors the displacement of the equipment. In case of malfunctions or the possibility of an accident, the system informs the personnel about the abnormal situation and stops the equipment operation. The module can carry out self-diagnostics of the system, timely informing the personnel about the need for maintenance and service of the equipment.

Thanks to this module, you will be able to monitor the operation of the elevator equipment at the highest level. This element can be easily integrated into the SMART Elevator monitoring system.

SMART Elevator is your ideal choice!

This development is an innovative product created by Grain Capital. Thanks to this system, you can automate all technological, economic and other processes at the elevator, minimizing the human factor in making technical decisions.

The basis of the program is the modular principle, where modules can work as separate elements or as part of the SMART-elevator system. The system's capabilities are not limited: it can be used to control not only production processes, but also the work of the accounting department, human resources department and security service.

An integral part of the system is "smart" equipment equipped with a variety of sensors, controllers and modules. The program complex has a convenient and clear interface, which can be connected to via the Internet regardless of location.