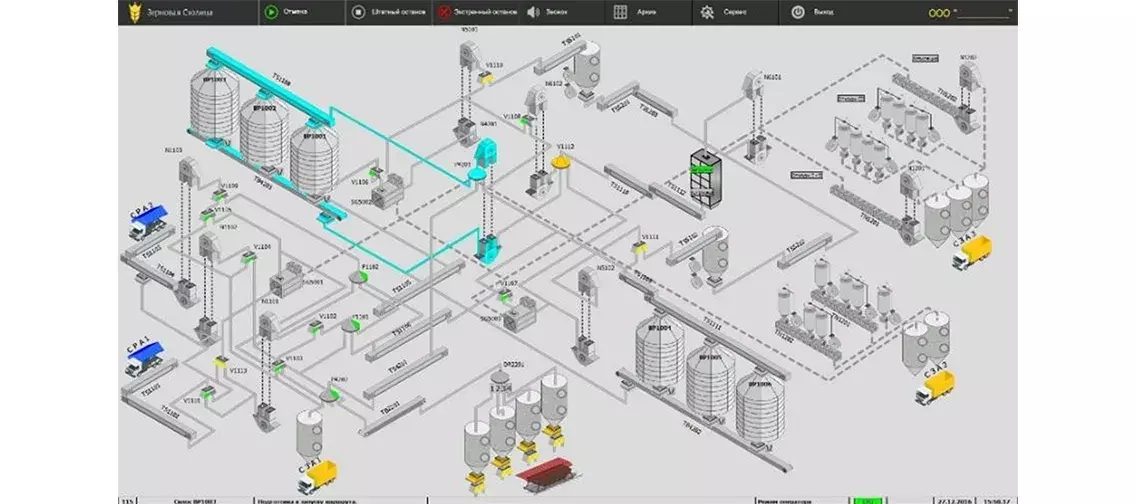

Automation of the grain storage with grain silo control for Buchachagroprom LLC

Project development, manufacturing, installation and debugging of a remote automatic control system for an elevator.

Product Feature:

- Electrical switching equipment and automation equipment are housed in “DKC” (Italy) cabinets, CQE design with IP54 protection level.

- Control and power distribution circuits are made using components from leading European manufacturers with a worldwide reputation: Siemens and Eaton (Germany).

- Application of PLC S7-1500 from Siemens.

- Application of distributed peripheral devices and distributed I/O devices Inline Phoenix Contact.

- A bus system is used, which makes the distributed energy system optimal for placement and safe for maintenance.

Power supply systems

Project implementation period:

September 2011

Project name:

Design, manufacturing, installation and debugging of power supply systems for the second elevator complex for grain reception and storage.

Primary goal:

- Management of technological and transport equipment.

- Implementation of remote control of technological and transport equipment.

- Control of grain limit levels in silos.

- Signaling of boundary and emergency parameters.

Scope of work:

- Development of design documentation for an electric power control system.

- Complete set of controls.

- Manufacturing of electrical power control panels.

- Installation of electrical power equipment.

- Commissioning of the elevator complex.

Technical means:

- Control system cabinets.

- Electric power equipment of the xEnergy "Moeller" series (transport bridges).

- Electrical switching equipment of the xStart “Moeller” series.

- Due to the need to increase production capacity, atomization management specialists designed and manufactured an electric power control system for a section of the elevator complex.

- All electrical switching equipment is housed in cabinets manufactured by Shneider Electric (France), made of galvanized steel 1.5 mm thick coated with a polymer powder coating with preliminary phosphating.

The boards are certified according to the international standard ISO 9001:2000 PRA 000 3966 dated December 1, 2005. Cabinet protection degree IP54.

Electrical distribution circuits are made on the basis of equipment from Moeller and Phoenix Contact, the main difference of which is a high degree of time between failures, fire resistance (class V2 in accordance with UL94 according to IEC 695-2-2 standard), vibration resistance, dust resistance.

In control cabinets and push-button stations installed at the equipment site, controls (buttons, switches) in IP65 version are used.

On the front panels of the starting and protective equipment cabinets there are M-O-A operating mode switches, indicators of the operation of transport mechanisms, the position of valves, and emergency levels.

Result:

Electric power control panels intended for the equipment of the new elevator complex are made from components of modern highly efficient systems xEnergy, xStart, Moeller and will be able to ensure reliable and energy-efficient operation of the equipment.

Installation and debugging work was completed in a short time, which allowed the customer to accept grain from the new harvest for storage without additional costs.

Grain temperature control system

Project implementation timeframe:

October 2011

- Grain temperature control system

- Grain temperature control system in silos.

Primary goal:

- Reducing the amount of grain loss caused by the process of self-heating of the grain mass.

- Presentation of information about the presence of foci of self-warming.

- Increasing the level of fire safety.

Scope of work:

Inspection of the object.

- Development of technical specifications.

- Development of a mounting unit for thermal suspensions.

- System components.

- System installation.

- Commissioning works.

Technical means:

ESKT-Ts system (digital electronic temperature control system).

Compound:

- Digital thermal suspensions TsTP.

- Information collection blocks BSI-12.

- Interface conversion block TRS232 – RS485 GSA V5.

- Power supply unit BPT-220-24/45.

- Work station.

Exercise:

- Control of product temperature in the silo throughout the entire filling volume.

- Display of temperature values.

- Generating an alarm when the temperature limit is exceeded.

- Tracking the dynamics of temperature changes.

- Archiving data, with the ability to view preliminary measurements, generating reports.

- To install thermal suspensions, Eurobudservice LLC specialists developed a design for a unit for attaching thermal suspensions to the load-bearing elements of the silo structure, adapted for silos produced by the OBIAL company.

The developed design minimizes the load on the silo roof elements that occurs during snowmelt.

The information collection unit polls thermal suspension sensors via the “1-WIRE” interface with the MicroLAN communication protocol. Communication between the information collection unit and the workstation is carried out via the RS-485 interface using the MODBUS communication protocol.

The complex is built in such a way as to reduce the number of terminals and other connections to a minimum, increasing reliability.

A PC with the ESKT-C software application installed on it is used as a workstation, which provides the ability to:

- view the temperature readings of each individual thermal suspension sensor of the maximum temperature in the suspension zone;

- represent the temperature value in the suspension zone in the form of colored fields;

- archive current data;

- present data in the form of graphs of temperature changes in the zone of each sensor;

- prevent grain spoilage by signaling an increase in product temperature in a certain zone using color indication;

- generate reports on exceeding temperature limits.

Result:

The mounted grain temperature monitoring system as part of a silo continuously monitors the grain temperature, tracking its changes at any point in the grain embankment, archives the temperature value without human intervention, reducing the likelihood of errors in measurements, allows you to analyze the collected data using graphs and tabular reports, allowing you to determine trends in temperature growth in grain storage areas, pockets of self-heating at the stage of their formation, saves energy resources spent on regular movement of grain for the purpose of cooling it.

Customer comment

Cooperation period:

2011-2017