SDAU for LLC "Brooklyn-Kyiv" (Louis Dreyfus Group)

Development, production and implementation of an electric power control system for a grain terminal.

Customer's situation

The management of Brooklyn Kyiv LLC was tasked with the design and construction of a grain handling complex as a new generation enterprise that meets the highest technological, energy and international environmental requirements.

The planned cargo turnover of the complex under construction should be 2.5 million tons of grain.

To achieve this task, the grain handling complex must be equipped with a high-tech, modern electric power control system that ensures reliable, safe operation with maximum equipment performance.

The development of technical solutions was entrusted to the department of the chief engineer of Brooklyn Kyiv LLC.

During the work, it turned out that the estimated capacity of the terminal complex is 5.6 MW and the available capacity for the operation of the Morskaya PPP grain terminal is not enough, since this substation is the main source of electricity not only for the OMTP, but also for the central part of the city. Thus, the construction of a grain terminal of the required capacity has become under threat.

It was decided to involve a specialized company in the development of the project, which offered the best energy-efficient solution.

Selecting a work contractor

The chief engineer of Brooklyn Kyiv LLC was asked to request the provision of his proposals for the implementation of this project to a number of specialized companies. GC "Grain Capital", having positive experience in implementing similar projects in the grain processing industry, received an advantage in selecting a work contractor.

The planned cargo turnover of the complex under construction should be 2.5 million tons of grain.

To achieve this task, the grain handling complex must be equipped with a high-tech, modern electric power control system, which will ensure reliable, safe operation with maximum equipment performance.

The development of technical solutions was entrusted to the department of the chief engineer of Brooklyn Kyiv LLC.

During the work, it turned out that the estimated capacity of the terminal complex is 5.6 MW and the free capacity for the operation of the Morskaya PPP grain terminal is not enough, since this substation is the main source of electricity not only for the OMTP, but also for the central part of the city. Thus, the construction of a grain terminal of the required capacity has become under threat.

It was decided to involve a specialized company in the development of the project, which offered the best energy-efficient solution.

Pre-project preparation

Having started work on this project, the specialists of the Grain Capital Group of Companies first of all developed a technological map for the work.

Meetings were organized with the management team of Brooklyn Kyiv LLC, specialists from the transport equipment manufacturer, as well as with process designers to obtain accurate information about the composition of transport equipment and its characteristics.

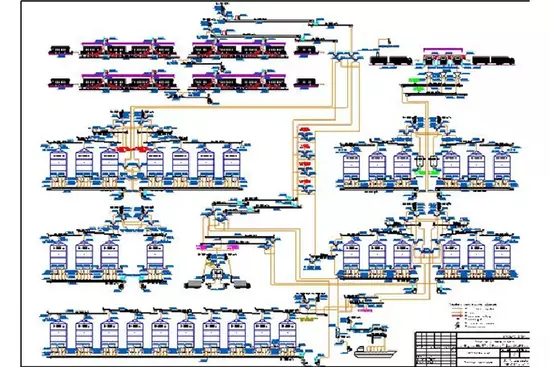

Based on the results of the meetings, the main problems that required solutions to optimize the progress of work were identified (Fig. 1):

- The layout of electricity distribution points, originally proposed for the construction of a new elevator, did not correspond to the rational distribution of loads.

- Distances from distribution points to electricity consumers led to large losses from voltage drop and heat losses on the cable.

- The choice of equipment on which the control system was supposed to be built did not meet the optimal energy efficiency criteria.

Design solution

At the design stage, a permanent group was organized, consisting of specialists from Brooklyn Kyiv LLC, representatives of companies involved in the construction of the complex, and technologists who presented the best option for transport flows in the field of circuit design of the Grain Capital Group of Companies.

The created group, in a short time, presented the best technical solution for the implementation of the task, satisfying the customer.

The calculation of the established and calculated current values was carried out taking into account the participation and simultaneity coefficients adopted in the grain industry.

The calculation of NKU cabinets was carried out with optimization of the placement of equipment in various sections, taking into account transport routes in order to avoid imbalance of load currents on the busbars of various sections during operation.

Electric drives of mechanisms with a power of more than 45 kW are controlled using soft starters with torque control.

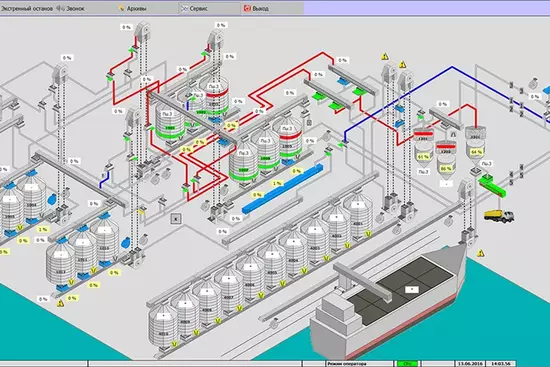

As a result, it was possible to develop an electric power control system for a grain transshipment terminal that allows:

- reduce forced losses of electricity to a minimum;

- reduce peak loads on general electrical networks;

- prevent blocking of the transport system during emergency situations;

- protect mechanisms as much as possible by damping shock loads.

Technical means

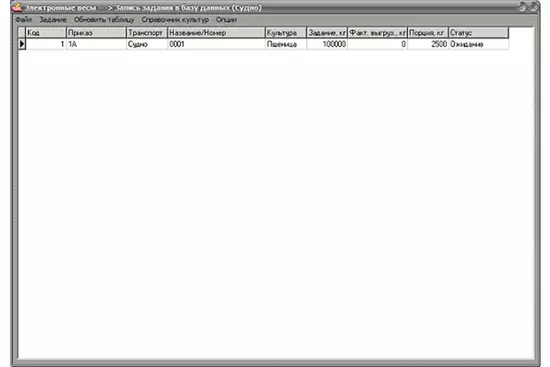

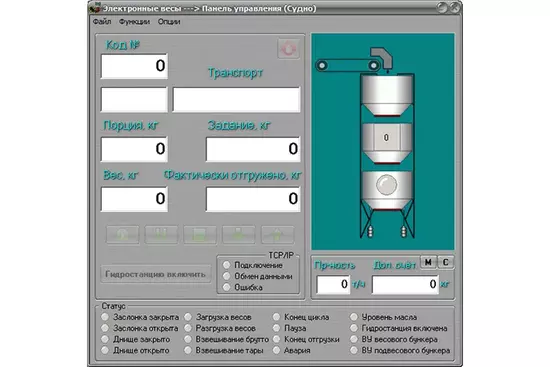

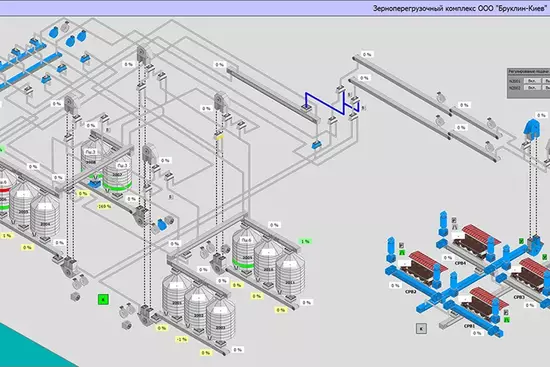

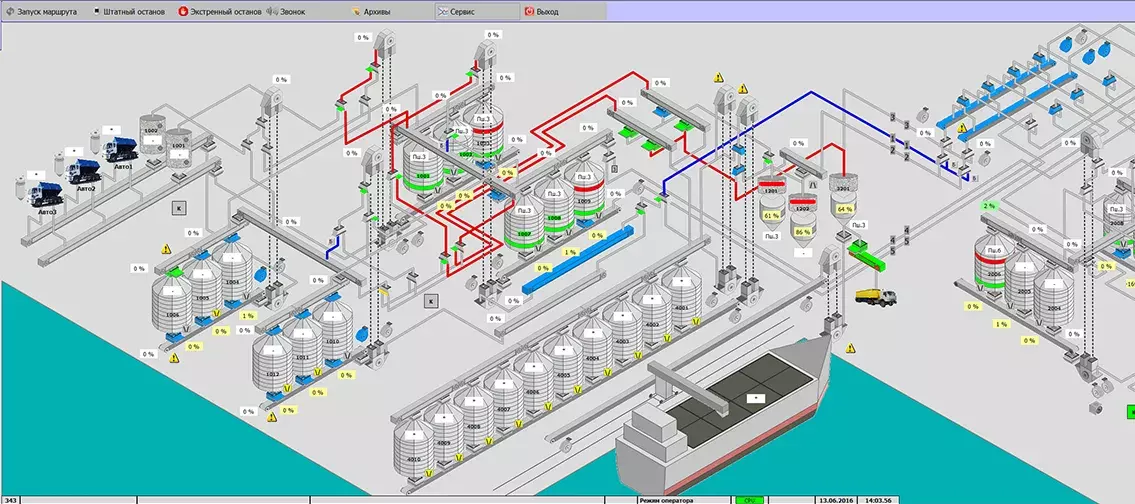

The electric power control system is made on the basis of technical means (Fig. 2.3):

- Power distribution system: SASI 60i – “Eaton” (Germany).

- Power circuit breakers: LZM, NZM, DILM – “Eaton” (Germany).

- Soft starters: SIRIUS 3RV44 – “Siemens” (Germany).

Result

Practical results of implementation

As a result of the work carried out by the Grain Capital Group of Companies on the development, production and implementation of the electric power grain terminal system of Brooklyn Kyiv LLC:

- it became technically possible to build a complex with the required productivity in conditions of limited energy supply;

- the grain terminal meets all regulatory requirements for energy efficiency approved by EU countries;

- costs for cable and wire products were reduced by 7%;

- reduced peak loads on general electrical networks by 5 times;

- energy consumption for moving a unit of product was reduced by 2%.

Customer comment

Implementation period:

2011-2014