Implementation of the SDAU at Beta Agro Invest LLC

Beta Agro Invest LLC has been conducting agricultural activities in the Donetsk region, Eastern part of Ukraine since 2000. The company grows crops, engages in livestock farming, provides additional services and is one of the leading agribusiness companies in Ukraine in terms of profitability.

Development, production and implementation of a remote automated elevator control system (SACS) at the Beta Agro Invest LLC enterprise.

Customer's situation

One of the business sectors of Beta-Agro-Invest LLC is flour production. In 2012, the simultaneous storage capacity of the flour production elevator was 10,000 tons.

- Increasing the profitability and efficiency of agricultural production thanks to the best business methods and the use of accumulated experience in modern and innovative agriculture.

- Increasing storage capacity in order to be independent from third party elevators.

That is why the company’s management set the task of completely reconstructing the flour milling production, which involves doubling the simultaneous storage capacity, replacing process equipment, increasing storage capacity and installing a modern electric power and automated control system.

If determining the composition of the equipment did not cause any difficulties for the technical specialists and management of Beta-Agro-Invest LLC, it became clear that there were not enough internal resources to implement an electric power supply project of such a scale. Therefore, it was decided to involve specialized companies in this work.

Selecting a work contractor

The head of the Gorlovka production site of Beta Agro Invest LLC was asked to request the submission of their proposals for the implementation of this project from a number of companies involved in the automation of technological processes.

The specificity of the automation section of this project was that in addition to the function of controlling technological equipment, the task of dispatching the complex of transport equipment was also to control the weight accounting of the product, as well as control the weight dosage according to given recipes in the process of preparing batches of threshing. In this case, it was necessary to connect automatic weighing and dosing devices from different manufacturers with the elevator system.

Proposals for the implementation of this project came from several companies in the country. GC "Grain Capital", having positive experience in implementing similar projects in the grain processing industry, received an advantage in selecting a contractor.

Criteria for the final selection of the work contractor

The final decision to select a contractor was based on the following:

- GC "Grain Capital" has specialists with more than 30 years of experience in the field of automation of grain processing enterprises.

- GC "Grain Capital" has positive experience in designing, manufacturing and implementing projects of this scale.

- GC "Grain Capital" has a powerful production base.

- GC "Grain Capital" is a developer of modern highly efficient technologies for managing elevator complexes.

- GC "Grain Capital" was able to put forward a proposal with the best price-quality ratio and the shortest installation and commissioning time.

Pre-project preparation

Meetings were organized with the management team of Beta Agro Invest LLC to clarify the situation about the current state of progress of work. Based on the results of the meetings, the main problems that required solutions to optimize the progress of work were identified:

- The fundamental technical solutions underlying the project are obsolete.

- The choice of equipment on which the control system was supposed to be built did not meet the optimal price-quality criteria.

- The technical solution adopted at the preliminary stage did not allow the implementation of dosage functions when preparing grinding batches.

Based on this, together with specialists from the Grain Capital Group of Companies, it was decided:

- View the technological diagram of the transport flows of the elevator under construction in order to optimize and bring them in line with modern trends.

- Review of fundamental electrical solutions to minimize energy costs, product loss and increase the level of safe operation of equipment and personnel.

- Conduct a series of technical meetings with the Buhler specialists supplying weighing control and bulk dosing equipment as part of this project, in order to synchronize the operation of this equipment with the control system.

- Due to the fact that the technological process uses a large number of devices with low power consumption, located at a significant distance from the central distribution center, it was decided to use distributed input-output technology when developing power distribution and control circuits.

- Ensure coordination of all work carried out within the framework of this project with all responsible persons interested in the further operation of the complex under construction.

- Break the work package into stages.

Stages of work:

- Formation of technical specifications.

- Design.

- Complete with control and automation equipment.

- Manufacturing of control and automation panels.

- Installation of monitoring, control and automation equipment.

- Setting up control, management and automation tools.

- Comprehensive setup of a remote automated control system.

Project documentation

At the design stage, a permanent group was organized, consisting of specialists from Beta Agro Invest LLC, representatives of companies participating in the construction of the Grain Capital Group complex, the Buhler company: technologists who presented the optimal option for the operation of equipment and dust removal systems, specialists in the field of circuit design, specialists in the field of algorithmic and software.

In the process of this work, innovative developments and the latest equipment from Siemens were used. And the use of contactless reversing starters of the 3RM12 series from Siemens became an event, as the first use of these devices in the food industry on the Eastern European market.

The created group made it possible to present the best technical solution for the implementation of the task to the satisfaction of the customer in a short time.

As a result, it was possible to develop a remote automated elevator control system (RAC), which allows:

- carry out prompt collection and processing of data on the condition of all peripheral equipment: conveyors, elevators, mechanisms, sensors, etc.;

- Diagnose accidents and deviations from the technological process without stopping, issuing an alarm and information about the nature of the malfunction;

- take measures to prevent blocking of equipment and stopping routes;

- control motor load currents and shut them down to avoid emergency situations;

- control in automatic and manual, locked or debugging modes;

- control the availability of product in bunkers and silos;

- carry out weight accounting of goods;

- display technological parameters in different graphical forms;

- maintain production protocols.

Work plan

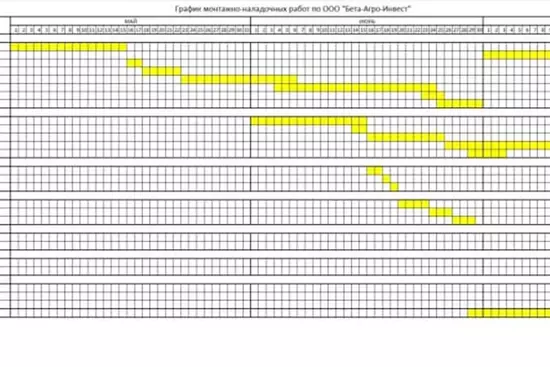

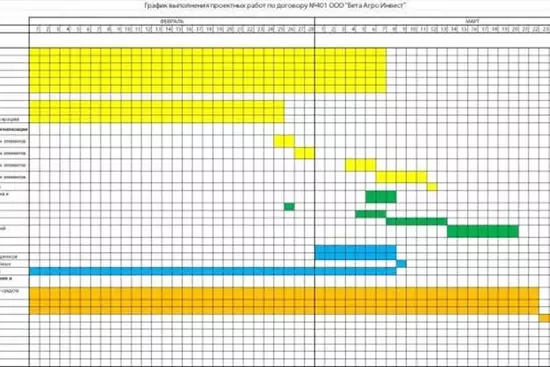

Before the design began, a complete list of works necessary to complete the task was determined.

As a result, a calendar schedule was generated indicating the responsible persons and the deadlines for completing the work stages (Fig. 1,2).

After drawing up the schedule, a project working group was organized. It included heads of structural divisions of Beta Agro Invest LLC and leading specialists of the automation department of the Grain Capital Group of Companies.

Technical means

- Control cabinets of the TS8 series with degree of protection IP56 manufactured by Rittal fig. 7.8.

- Eques Technology “Wohner” busbar power distribution system.

- Electronic ballasts from the Sirius Innovation “Siemens” line.

- The control system is based on technical equipment from Siemens and Phoenix Contact.

- Central processor: CPU S7-315 PN/DP.

- Distributed peripheral system: ET200M, Axioline.

- I/O modules: ET200M, Axioline.

- Weight controller: MZAH.

- Weight controller: MEAG-MDD.

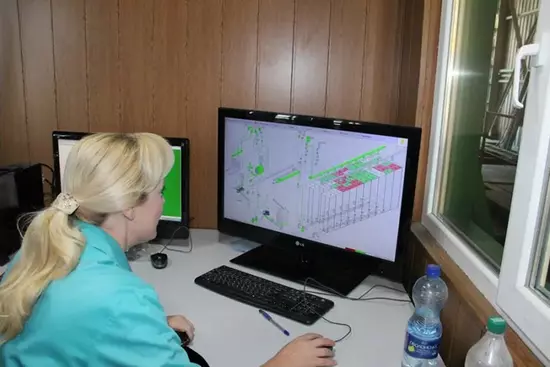

A computer with a specialized SCADA system of our own design installed on it is used as an operator workstation. According to its architecture, the designed system belongs to the class of multi-level distributed systems; USO communication gateways are located in automation cabinets, interconnected by communication lines using the ProfiNet and ProfiBus protocols.

Visualization is implemented on a specialized SCADA system, which also performs the functions of controlling technological equipment and displaying all the information necessary to conduct the technological process.

Result

As a result of the work carried out by the Grain Capital Group of Companies on the development, production and implementation of a remote automated control system for the elevator of Beta Agro Invest LLC:

- Reduction of implementation time in relation to similar systems due to the use of distributed input-output systems by 1.7-1.9 times.

- Reducing the cost of cable and wire products through the use of distributed input/output systems by up to 30%.

- Cost reduction keeps the system by reducing the number of cable products by up to 26%.

- Reducing the amount of construction financing by reducing the implementation time and reducing the cost of automation and electrical power control equipment by up to 15% while increasing the storage capacity to 20,000 tons.

- Reducing training time for SDAU operators due to the versatility of the interface used to 4-7 days.

- Reducing energy consumption for moving a unit of product due to algorithmic optimization of grain transportation routes from 10% to 12%.

- Reduction of forced grain losses through the use of a highly efficient system for accounting and dosing of the product by up to 5%.

- Reducing maintenance costs by using highly reliable electrical power and software control equipment produced by the world's leading manufacturers by up to 17%.

Customer comment

Implementation period:

2013 р.