Automation of painting and drying shops

High quality of painting - durability of equipment!

The key to survival for Ukrainian production enterprises is constant modernization of the production base, allowing not only to optimize costs and production process, but also to significantly improve the quality of products.

One of the old partners of GC "Zernovaya Stolitsa" asked us about the possibility of organizing a conveyor-type drying line for the paint shop. After all, the solutions offered on the market by foreign manufacturers cost several thousand euros, which makes improving the quality of painting a risky investment with a long payback period.

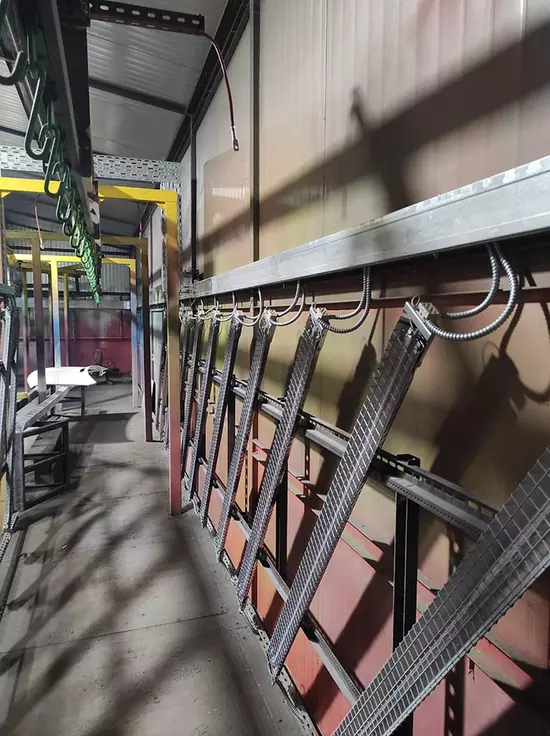

Under the guidance of the Chief Technologist of GC "Zernovaya Stolitsa" O. Stepanov. A. Stepanov developed the concept, designed, manufactured and assembled the mechanical part of the line by the company's own forces.

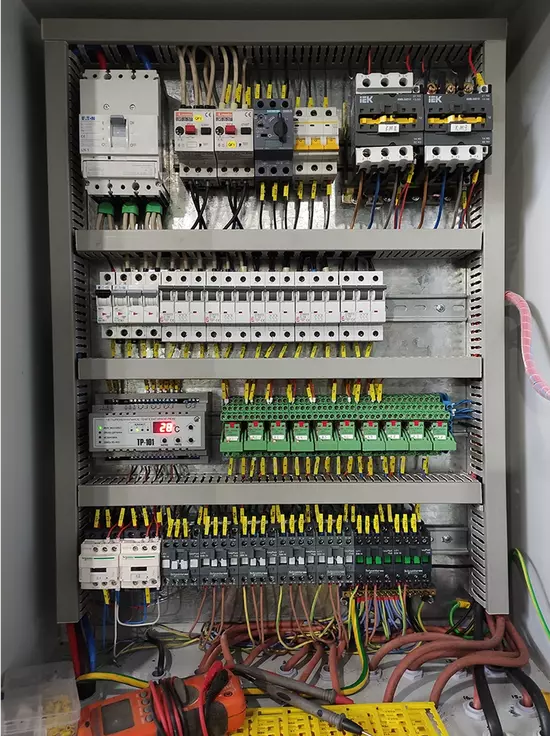

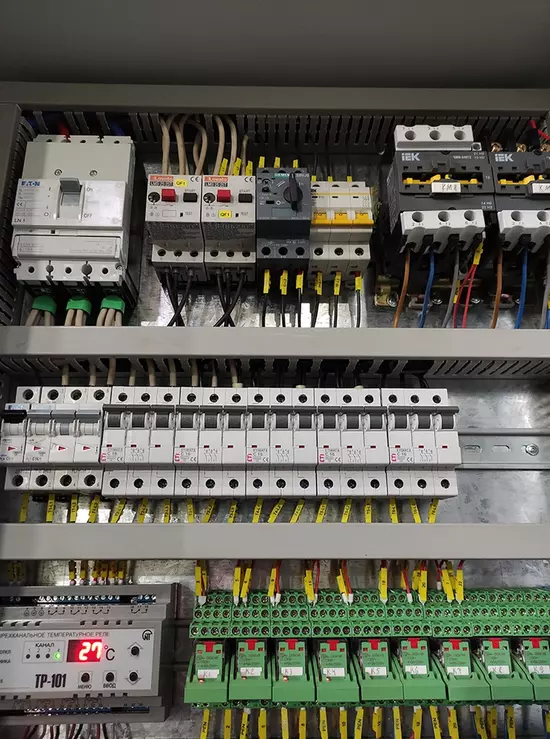

The head of the service department Nikitenko V. V. Nitenko, head of the service department, developed the technical specification and project, carried out production, installation and commissioning of the automation system of the paint shop.

"When using infrared radiation, it is not the air in the room that is heated, but the part itself. This method of drying contributes to better curing of the coating, speeds up the process of production of finished parts and significantly saves energy" - reports V.V. Nikitenko.

As a result of works performed in the period from January to February 2021, the customer received a fast and high-quality metal preparation line for painting and drying, which has a much higher productivity, as well as significantly minimizes the risks regarding the quality and timely completion of work.

Due to the significant depth of production, almost all materials and equipment, except for specific positions of the automation system, were used domestically, so the cost of the solution turned out to be more than competitive. Powerful capabilities and qualification of the engineering sector of the company ensured modernity and compliance with all labor safety requirements for this type of production sites:

- evaporation of solvent from the paint layer takes place before the part enters the working area;

- a heat curtain separates the drying area from the paint shop, preventing explosive vapors from the shop from entering the heating zone;

- four temperature control zones;

- automatic heating shutdown in the absence of forced ventilation;

- light and sound notification of an emergency situation.

The modernization resulted in:

- Virtually complete automation of the entire drying process, which minimized human influence on the technological process.

- Significant improvement in paint quality, increasing the service life of the parts.

- Increased productivity of the painting line due to faster drying process.

- The impact of harmful substances on the working staff is minimized.

It remains to be added that in March the paint shop with the new drying line successfully passed the relevant certification by the regulatory authorities and was fully commissioned.