Experience in increasing the competitiveness of grain terminals

High-performance equipment and environmental safety are key aspects of modern grain marine terminals.

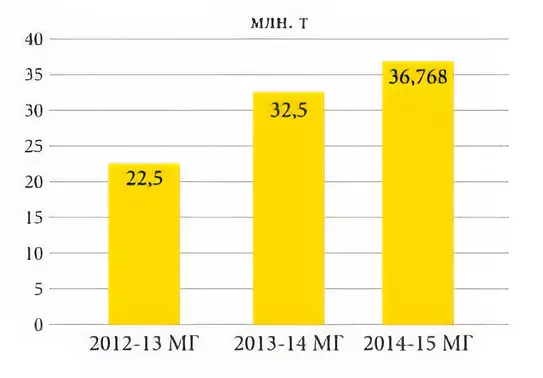

Ukraine's agricultural sector continues to demonstrate high growth rates despite the challenges of recent years. This is confirmed by Ukraine's position in the global grain market. In 2023/2024 marketing year, our country holds a place in the top three leading exporters of grain in the world.

According to the Administration of Sea Ports of Ukraine, last year about 40 million tons of grain were exported through sea ports, which is 22% more than in the previous year. Grain remains the main export item, accounting for more than 35% of total cargo transportation at the ports.

Among the leading grain exporting companies are such giants as Nibulon, Louis Dreyfus Ukraine, Glencore, Bunge Ukraine and GPZKU. Grain handling operations are among the most competitive and strategically important for the country's economy.

Grain Capital's experience with grain terminals

Grain Capital's experience of working with grain terminals in the Black Sea has highlighted four main problems faced by grain terminals:

- Loss of grain quality during receiving, shipping, handling and storage.

- High energy consumption and operating costs.

- Low throughput capacity.

- Emissions to the environment and waste disposal.

- Quality losses.

According to the monitoring of the Ministry of Agrarian Policy of Ukraine, in 2023 the increase in damaged grain, particularly corn, at transshipment elevators with stationary mechanization amounted to 2.5-4.5%. Prolonged storage of grain leads to increased temperature and humidity inside, which can lead to loss of grain mass and quality up to 3-5%, and in cases of self-heating - up to 8-12%.

For example, a transshipment complex with an annual turnover of 2.5 million tons of grain can lose up to 4.5 thousand tons of marketable grain annually, which is equivalent to more than 18 million UAH. Settlement of these losses is an important aspect of every exporter's work, but preservation of product quality should be the first priority.

Grain Capital offers the following solutions to minimize grain losses:

- Replacement of traumatizing equipment (bucket elevators, scraper conveyors) with belt conveyors.

- Use of gravity transport with gentle modes of movement of grain streams.

- Gentle loading-unloading of grain in transportation equipment.

- Synchronization of loading and unloading speeds.

- Eliminate product contact with structural elements that can cause damage.

- Installation of effective active tank ventilation systems.

High energy intensity and operating costs

Grain dust remains one of the most hazardous factors in production, especially in category B2 (explosive environments). In 2023, there were more than 60 cases of grain dust explosions worldwide, resulting in significant human and financial losses.

With increasing urbanization, the issue of environmental safety is becoming critical. In particular, the proximity of grain terminals to resort areas and residential areas requires strict control of emissions into the environment. The issue of aspiration waste utilization is also important. For example, aspiration air emissions can reach up to 1,500 mg of product per m³, which on a yearly scale equates to more than 300 tons of lost mass.

Grain Capital's dust control solutions include:

- Installation of dust suppression sources.

- Use of local aspiration plants adapted to actual operating conditions with minimum energy consumption.

Most of these solutions have already been successfully implemented at the enterprises of Odessa, Chernomorsk and Yuzhny ports.

Modernization efficiency: achievements and figures

During modernization the main attention was paid to reduction of losses due to grain crushing. If earlier losses were 4-5% (40-50 UAH/t), after modernization and optimization of routes they decreased to 2-2.5% (25-30 UAH/t), which provided savings of 40%. The total economic effect at the enterprises of Odessa and Ilyichevsk seaports amounted to about UAH 20 mln for the last 5 years.

One of the key achievements was the reduction of specific energy costs from 1.62 kWh/t to 0.62 kWh/t after the introduction of new technologies. This allowed to reduce energy costs by 62%, which provided an economic effect of UAH 1.5 mln over 5 years.

The priority in modernization was to increase the throughput capacity of grain terminals and reduce the downtime of sea vessel freight. If before the reconstruction the shipment of 1 ton of grain took 14 minutes, after the introduction of new transport lines this time was reduced to 9 minutes, which provided a 37% reduction. The total economic effect for 5 years amounted to more than 700 thousand US dollars.

Environmental results of modernization

The introduction of a three-level dust suppression and local aspiration system has significantly improved the environmental condition of the production facilities. Air dustiness in working areas decreased to 3-3.5 mg/m³, emissions into the environment - to 15-20 mg/m³, which is significantly lower compared to the previous indicators of 250 mg/m³. Energy intensity of cyclone dust removal systems decreased from 0.1 kWh/t to 0.03-0.04 kWh/t, and emissions were reduced to 5 tons per year.

The application of the latest environmental safety systems made it possible to achieve levels that meet the international standards of "Green Construction" and "Green Buildings". The total economic effect from the implementation of these systems in 2024 amounted to more than UAH 3.5 mln.

Thus, the accumulated experience of Grain Capital is now being implemented in the design, construction and modernization of grain terminals in Ukraine, providing significant competitive advantages for grain transshipment business.

Author of the article: A.I. Gaponyuk, Dr. Sci. in Engineering, Professor, Odessa National Technological University, Odessa.