Development of project documentation for Novotech Terminal LLC

When designing the Novotech-Terminal grain handling complex, the terminal management set the task of creating an effective terminal. High-level enterprises effectively differ from other terminals in terms of energy and technological indicators, and also meet international environmental requirements.

After the implementation of the project phase, the Customer contacted us with a request to perform a technical audit of the project for the further development of the terminal, carried out by one of the design organizations. As a result of optimization measures and joint work with the company’s management, solutions were proposed that allowed:

- optimize the use of the territory;

- ensure flexibility of the technological scheme;

- increase simultaneous storage volume;

- optimize energy intensity;

- increase terminal security;

- optimize the volume of equipment used;

- provide additional transshipment opportunities - loading special containers, stuffing;

- ensure weight and quality accounting of grains when supplying road and rail transport.

Scope of work:

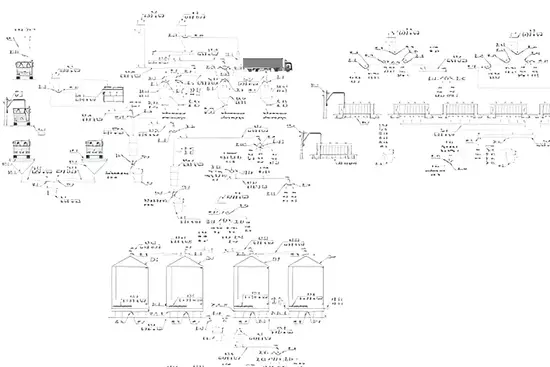

Development of design documentation at the P&R stage of a grain terminal project with an annual turnover of 3 million tons.

Characteristics of the designed object:

- Total capacity – 8 silos – 61,000 cubic meters.

- Unloading station for 6 wagons – 500 t/hour.

- Vehicle unloading station for 2 vehicles, 22 m each - 80 t (500 t/hour).

- Shipment of grain to special containers – 216 cubic meters. (500 t/hour).

- Shipment to vessel – 1000 t/hour.

- Cleaning – 800 t/hour.

- Transportation occurs by scraper, belt conveyors and elevators.

- The transport equipment is adopted with a capacity of 250 t/h, 500 t/h and 1000 t/h.

- The units being designed belong to category “B” for explosion and fire hazard, fire resistance degree “ΙΙΙа”.

- Modern aspiration and automation system.

Customer comment

Cooperation period:

2016-17