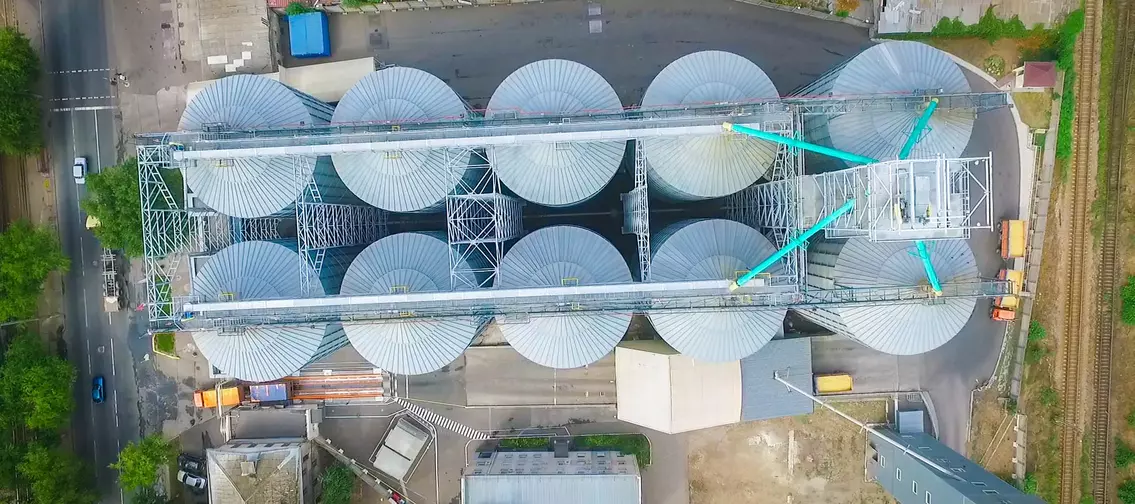

Construction and installation of PJSC Ukrelevatorprom (ADM)

Odessa

Company:

PJSC "Ukrelevatorprom" (ADM)

Location:

Odessa, st. Black Sea Cossacks, house No. 52/1

Characteristics of the object

The port grain transshipment terminal with a storage capacity of 213 thousand tons is designed to receive large quantities of grain crops and ship them to sea vessels. The reception of raw materials from road transport, cleaning, drying, storage and shipment to sea vessels is taken into account.

Design work:

- Project: "Reconstruction of the receiving and treatment unit and the release gallery with a capacity of 500 t/hour."

- Technical re-equipment of super-silo galleries of section No. 2 (ensuring a minimum period of production shutdown).

- Development of design documentation stage of the RP “Installation of a sampler at the wagon unloading station.”

- Development of design documentation for the reconstruction of the auto unloading station.

Construction and installation:

- Construction of a holiday gallery with a capacity of 500 t/h according to the project. “Reconstruction of the receiving and treatment unit and release gallery with a capacity of 500 t/h” – general contract – 2014.

- Technical re-equipment of super silos at site No. 2 (increasing productivity from 350 to 600 t/h) - 2015.

- Installation of a receiving unit for railway transport.

- Installation, debugging, commissioning of an automatic process control system based on Siemens equipment - 2015.

- Technical re-equipment of the car receiving unit: increasing the number of cars accepted through the use of modern car unloaders and increasing the productivity of transport lines (dismantling/installation, equipment manufacturing) - 2017.

Aspiration:

- Development of a section of the PU project for dust removal of silo galleries.

- Development of a section of the project for PU systems for dust removal of hopper scales, dumping boxes of belt conveyors.

- Development of a detailed design for dust removal SPM-1200.

Automation:

- Reconstruction of the system for remote automated control of a port terminal (SDAU), with a simultaneous storage capacity of 210,000 tons.

- Design, manufacture, installation and debugging of an additional automated workstation of the SDAU elevator.

Production and supply of equipment:

Transport equipment:

-

Belt conveyors ZEO-BC, Q=500 t/h.

Aspiration equipment:

- Filter cyclones ZEO-FC, Q=6000-15000 m3/h.

- Local filter ZEO-FG series.

- Cassette-bag filter: ZEO-FK, Q=20000 m3/h.

Manufacturing of metal structures:

Elevator complex (transport galleries, elevator and turning towers, canopies and shelters).

Customer comment

Cooperation period:

2006-2017