Project to control the temperature of grain in a silo for Vitchyzna LLC

Grain temperature control system in the silo - August 2010. Design, manufacturing, installation and commissioning of electric power and remote automated elevator control systems for the new and old complex - October 2012.

Grain temperature control system

Project implementation period:

August 2011

Project name:

Grain temperature control system in the silo.

Primary goal:

- Reducing the amount of grain loss caused by the process of self-heating of the grain mass.

- Presentation of information about the presence of foci of self-warming.

- Increasing the level of fire safety.

Scope of work:

- Inspection of the object.

- Development of technical specifications.

- Development of a mounting unit for thermal suspensions.

- System components.

- System installation.

- Commissioning works.

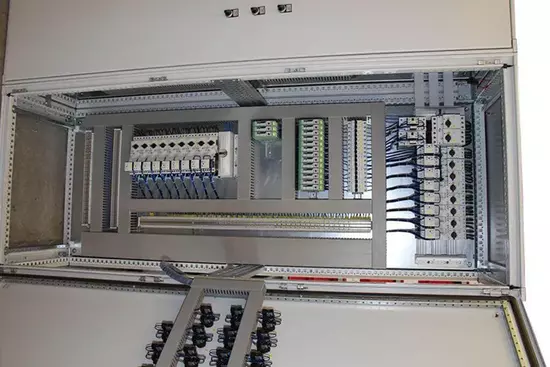

Technical means:

- ESKT-Ts system (digital electronic temperature control system).

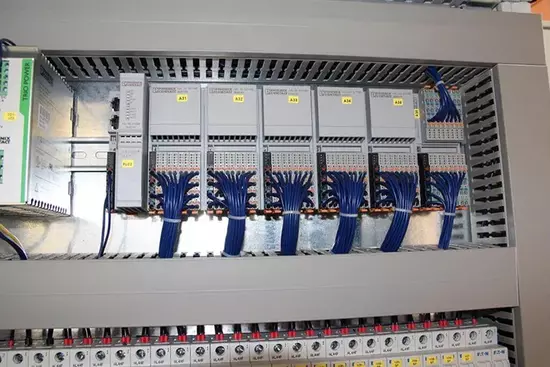

- Compound:

- Digital thermal suspensions TsTP.

- Information collection blocks BSI-12.

- Interface conversion block TRS232 – RS485 GSA V5.

- Power supply unit BPT-220-24/45.

- Work station.

Exercise:

- control of product temperature in the silo throughout the entire filling volume;

- display of temperature values;

- generation of an alarm when the temperature limit is exceeded;

- tracking the dynamics of temperature changes;

- full maintenance of statistics, with the ability to view preliminary measurements;

- generation of reports.

- The design of the roof of the mounted silo does not allow the use of its load-bearing elements as fastening elements for thermal suspensions.

- Specialists of Eurobudservice LLC developed, manufactured and installed a mounting structure for thermal suspensions that do not increase the load on the silo structure. The mounting unit for the thermal hangers of the central heater is designed in such a way as to avoid bending and twisting loads as much as possible during installation and operation and allows to avoid destruction of the silo structure in cases where the permissible pulling load on the thermal hangers is exceeded.

Temperature control is carried out by thermal suspensions of the TsTP type, which are a cable-rope, inside of which, along its entire length, there are DS18B20 digital sensors from Dallas Semiconductor.

The information collection unit polls thermal suspension sensors via a 1-WIRE interface with the MicroLAN communication protocol. Communication between the information collection unit and the workstation is carried out via the RS-485 interface using the MODBUS communication protocol.

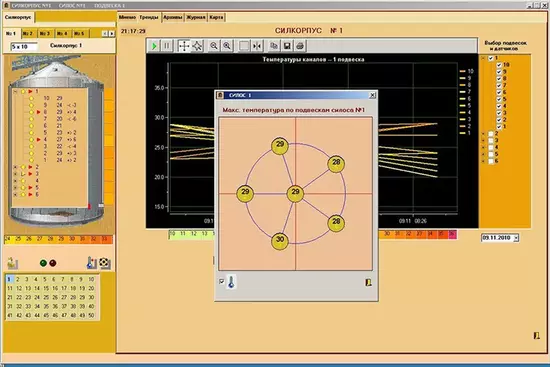

The complex is built in such a way as to reduce the number of terminals and other connections to a minimum, increasing reliability. A PC with the ESKT-C software application installed on it is used as a workstation, which provides the ability to:

- view the temperature readings of each individual thermal suspension sensor of the maximum temperature in the suspension zone;

- represent the temperature value in the suspension zone in the form of colored fields;

- archive current data;

- present data through graphs of temperature changes in the zone of each sensor;

- prevent grain spoilage by signaling an increase in product temperature in a certain zone using multi-colored indication;

- generate reports on exceeding temperature limits.

Result

The mounted grain temperature monitoring system as part of the floor storage continuously monitors the grain temperature, tracking its changes at any point in the grain mound, archives the temperature value without human intervention, reducing the likelihood of errors in measurements, allows you to analyze the collected data using graphs and tabular reports, allowing you to determine trends in temperature growth in grain storage areas, pockets of self-heating at the stage of their formation, saves energy resources spent on regular movement of grain for the purpose of cooling it.

Remote control system

Project implementation period:

October 2012

Project name:

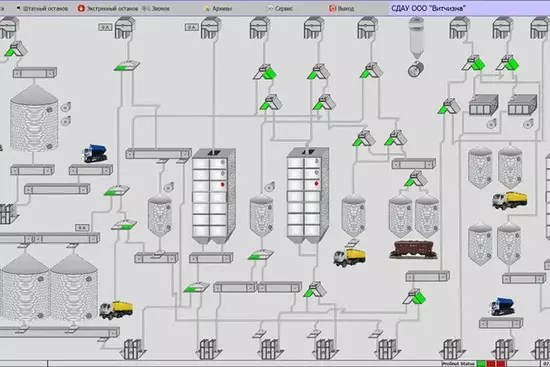

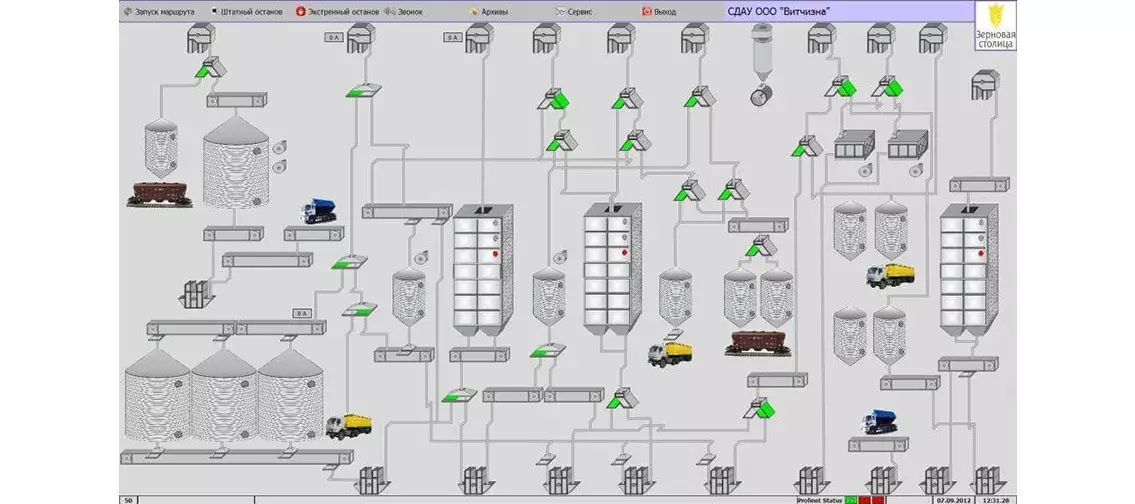

Design, manufacturing, installation and debugging of electric power and remote automated elevator control systems for new and old complexes.

Primary goal:

To develop and implement a system of electric power and remote automated control of an elevator (SDAU), which would allow:

- control all peripheral equipment: conveyors, elevators, valves, tilting valves, aspiration systems, etc.;

- promptly collect and process data on the condition of all peripheral equipment: conveyors, elevators, mechanisms, sensors, etc.;

- continuously diagnose accidents and deviations from the technological process with the issuance of alarms and information about the nature of the malfunction;

- take measures to prevent blocking of equipment and stoppages of routes;

- control motor load currents and shut them down to avoid emergency situations;

- control in automatic and manual, locked or debugging modes;

- control the availability of product in bunkers and silos;

- prevent mixing of grain crops;

- display technological parameters in different graphical forms;

- maintain production protocols.