The era of smart elevators or how to increase profits

The world, including Ukraine, is gripped by the digital revolution. Technical progress is relentlessly advancing, penetrating all spheres of life, changing the ways of communication, organization of work, forms of education and leisure. The Fourth Industrial Revolution, in simple terms, is about connecting the things around us to a single network of information exchange, including production devices and grain elevator equipment.

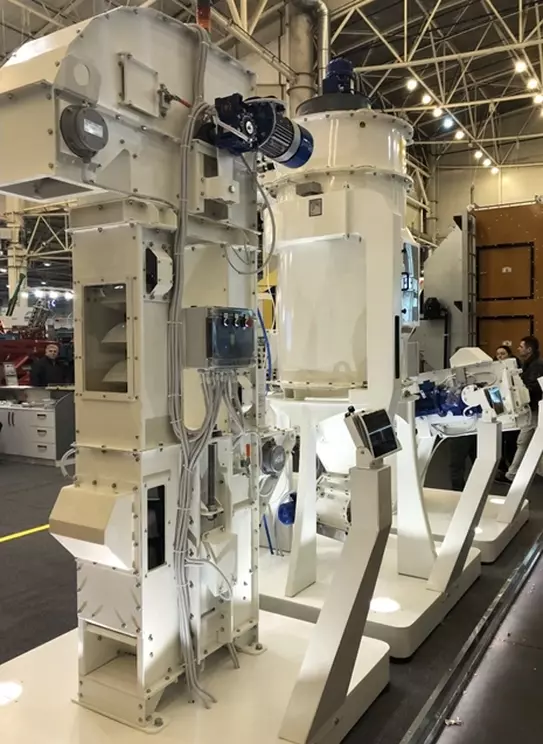

Introducing our innovative product, which has been shaped by years of research and testing. This is our pride and the future of the entire elevator industry - SMART-Individual: An automatic system for analyzing and monitoring the performance of elevator equipment, controlled from a tablet from anywhere in the world.

It prevents unscheduled shutdowns, emergencies, fires, explosions, etc.

Minimizes the number of operating personnel to a reasonable minimum, while eliminating the complexity and cumbersomeness of the "classic" automation concept.

A system that does not require costly licensing and complex implementation, and is therefore available to both large agroholdings and mini-elevators.

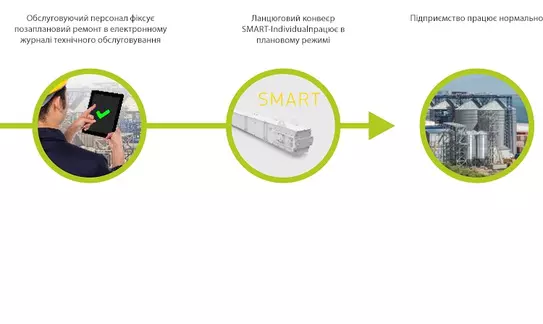

Allows for timely routine work and maintenance, notifying the manager and maintenance staff of the need for repairs in advance.

Comes pre-installed on all Grain Capital standard transportation and aspiration equipment.

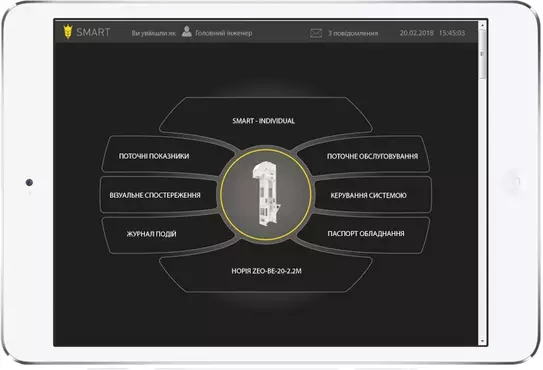

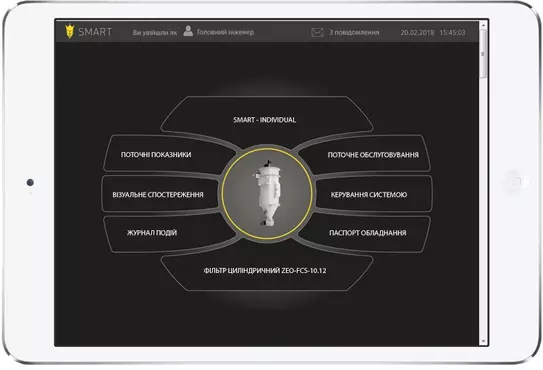

SMART-Individual is a software and hardware complex. Data is transmitted using sensors installed on the equipment, and control is carried out through the control unit (controller). The control unit polls the sensors and buttons, starts and controls the operation of the equipment and its shutdown, and the status of the equipment is displayed in the web interface.

Unique features:

- Monitoring of all possible equipment parameters: vibration and position, temperature, dust, presence of product in the equipment.

- Electronic documentation is always at your fingertips: delivery lists, data sheets, installation, operating and maintenance instructions.

- Intelligent Maintenance System (IMS), which alerts you to the need for maintenance, indicates what work needs to be done, what consumables and spare parts are required, what tools are needed.

- 24/7 online service from the manufacturing plant, which is always close by.

- User-friendly web interface on your tablet with the ability to connect locally via Wi-Fi, through the company network from anywhere in the world. Even if your equipment is working in the field, thanks to 3G-4G modem it will be online.

- Built-in intelligent assistant will always report the results of work for different periods: day, week, month. The main operating parameters are recorded: hours worked, power consumption, etc.

Practical examples of use

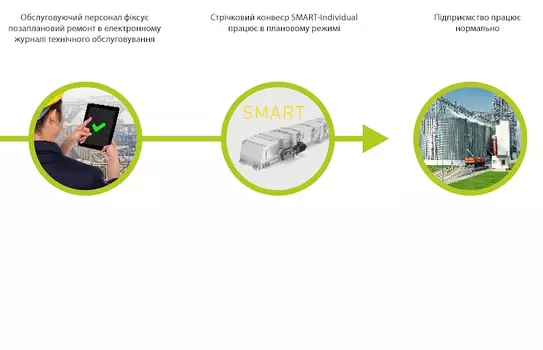

SMART-Individual is installed on the scraper conveyor

Classical conveyor: Depending on the specific case, which is individual for each enterprise, under favorable conditions, positively influencing the speed of repair works, when the spare parts kit is available at the enterprise, the on-duty team of repairmen is prepared, there are no unfavorable weather conditions and daylight hours, the elimination of the accident consequences will cost about 15,000 UAH. Under unfavorable conditions, especially when the ship is being loaded, the losses may reach one million hryvnias.

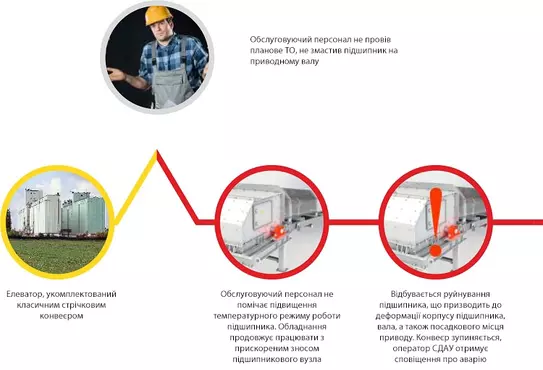

SMART-Individualvidual is installed on the belt conveyor

Classical conveyor: Losses depend on the specific case, which is individual for each enterprise, under favorable conditions, positively affecting the speed of repair work, when the spare parts kit is available at the enterprise, the on-duty crew of fitters and repairers is prepared, there are no bad weather conditions and daylight hours, the elimination of the consequences of the accident will cost about 30,000 UAH. Under unfavorable conditions, especially when the vessel is being loaded, the losses may reach one million hryvnias.

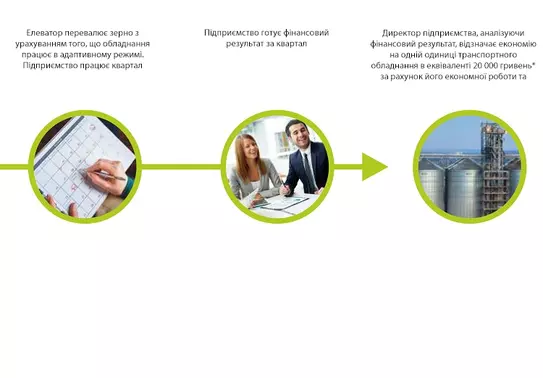

SMART-Individual is installed on the Bucket Elevator

Classic Noria: Savings were measured at an operating plant, where a SMART-Individual 200 t/h noria with a height of 35 meters, 37 kW drive, average working intensity of 15 hours per day, and an electricity cost of 2 UAH/kWh was in operation.

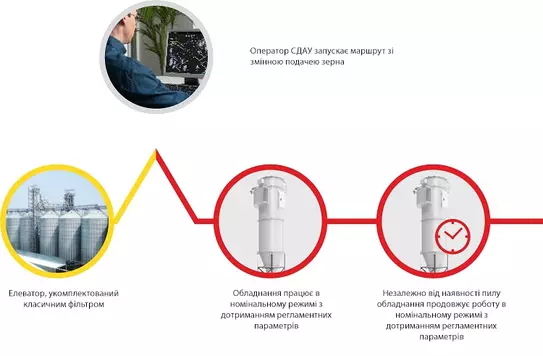

SMART-Individual is installed on the filter

Classic filter: Savings were measured at an operating plant with a ZEO-FCS 20000 SMART-Individual filter with a 22 kW fan, a 0.8 m³/min compressor, an average operating intensity of 15 hours per day, and an electricity cost of 2 UAH/kWh.

Summary

SMART-Individual is a cost-effective system that provides:

- up to 20% energy savings through reduced equipment power during downtime and variable savings during operation depending on load;

- up to 20% increase in the operating life of the equipment;

- up to 25% compressed air savings (on filtering equipment);

- saving on spare parts due to prevention of emergency situations;

- minimization of maintenance personnel on the elevator to a reasonable number;

- no installation costs, as the system is delivered from the factory together with the equipment;

- does not require expensive equipment, licenses and certificates.

More information about SMART-Individual: +38 067 509 77 70