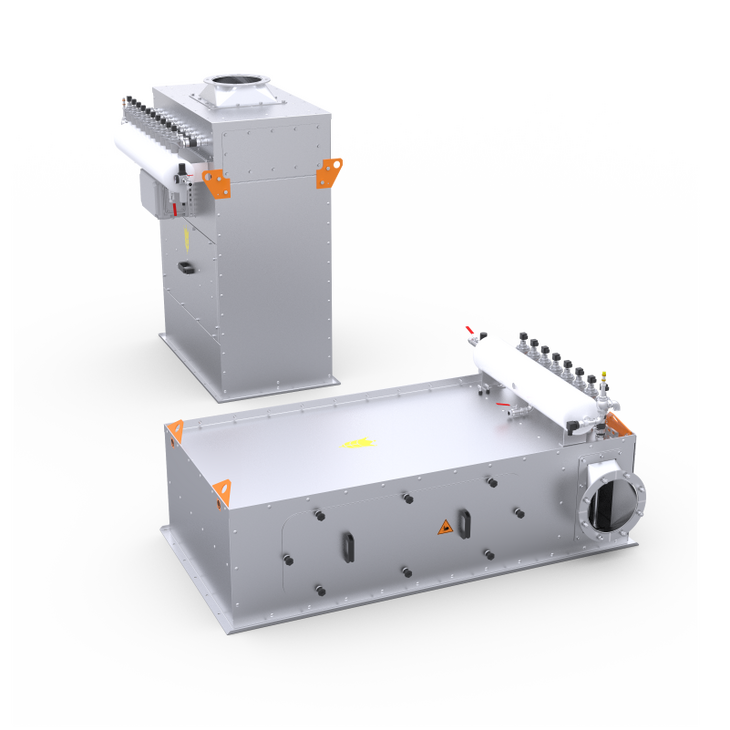

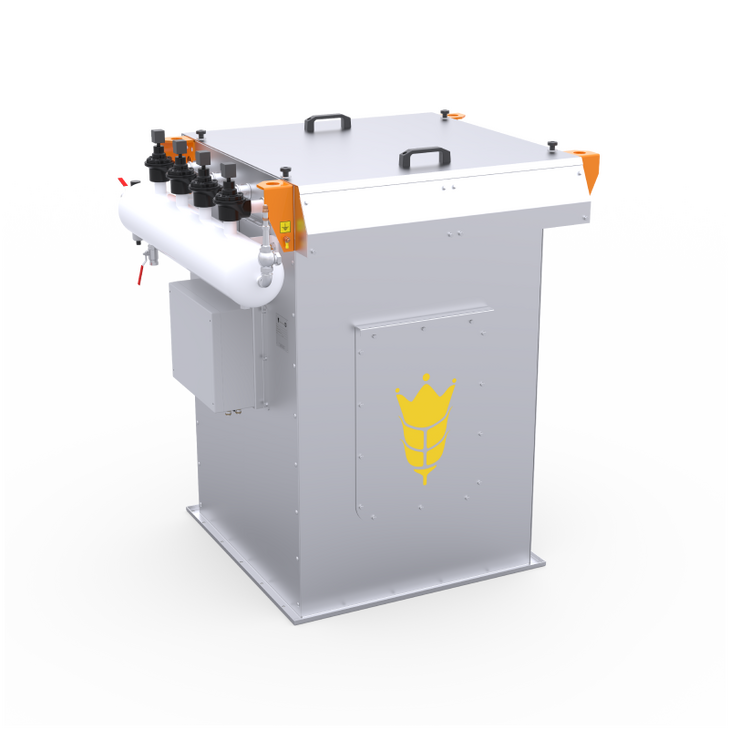

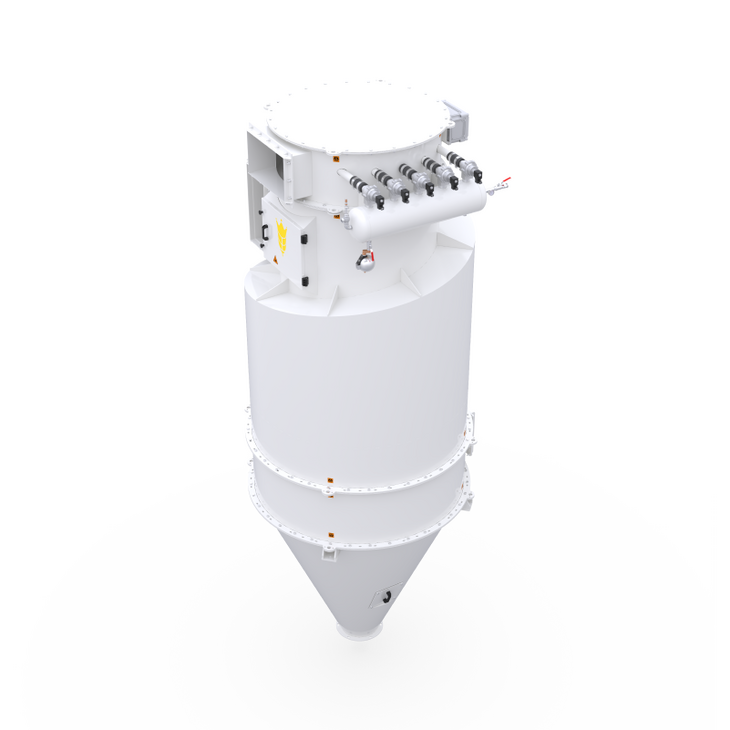

The ZEO-FCS cylindrical bag filter is a highly efficient aspiration equipment. These bag filters operate on the principle of centrifugal separation.

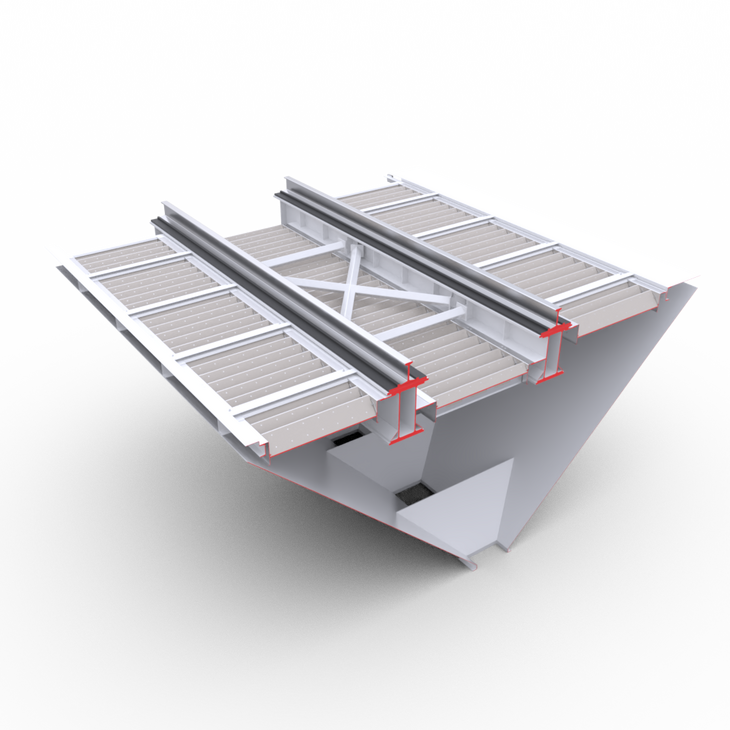

In the ZEO-FCS, a tangential inlet directs the inlet flow along the forming surface of the cylindrical bag filter housing. This inlet causes the dust-air mixture to rotate and the particles are subjected to centrifugal and inertial forces. Large particles of the mixture lose speed and roll down into the collecting cone. The remaining fine dust enters the second stage of filtration – the filter elements. The cleaned stream penetrates the filter cloth and enters the chamber, while the dust remains on the surface and in the pores of the filter sleeves. Thanks to the plant's fully automatic cleaning system, the filter bags are effectively cleaned by short pneumatic pulses, which can be timed or controlled by a differential pressure. After the cleaning cycle, the bag filter returns to its original performance.

The bag filter ensures stable filtration of the dusty environment of the elevator equipment even under conditions of high dust concentration. The unit can be integrated or operate as a stand-alone filtering equipment. Thanks to the bag equipment, the filter maintains continuous operation.

- High efficiency of the air filter – 99.6%.

- Increased regeneration efficiency due to optimally selected geometric parameters of the nozzles and filter elements of the bag filter.

- The filtering units are assembled from standard modules, which allows for high quality workmanship and ease of assembly.

- The model range is available in various design combinations, which provides flexibility and adaptability to almost any production process.

- The use of reliable components from leading global manufacturers.

- The cylindrical design of the bag filter guarantees the absence of “dead corners”, thereby eliminating the retention of the filter product and the hovering of small particles in the housing.

- Minimization of compressed air consumption by the filter due to a smart regeneration system, which is produced depending on the operating conditions of the plant.

- The bag filter can be connected to existing centralized compressed air systems.

- The use of sleeves made of high-performance filter fabrics manufactured using nanotechnology.

- Low load on the filter fabric, which prolongs its durability and ensures reliable operation (compared to imported analogues).

- The filter can be installed in an open area.

- Operating temperature range from -10 °C to +50 °C (subject to preparation in accordance with the product passport)

- Can be manufactured in a version suitable for use in ATEX 21 and ATEX 22 explosion hazard areas.

L-series | P-series | |

Warranty, months | 18 | 24 |

Operation mode | Regularly throughout the year | Daily and continuously |

Housing material |

|

|

Filter regeneration system | Europe (Camozzi) | Europe (Camozzi) |

Air treatment system | Europe (Camozzi) | Europe (Camozzi) |

Filter element (antistatic, oil and water repellent) | Europe (PES 500) | Europe (PES 500) |

Pressure differential sensor | - | Available |

Pressure sensor | - | Available |

Control unit | IP 56 | IP 66 |

Coating | Polyurethane | Polyurethane |

RAL | 7015 | 5010 |

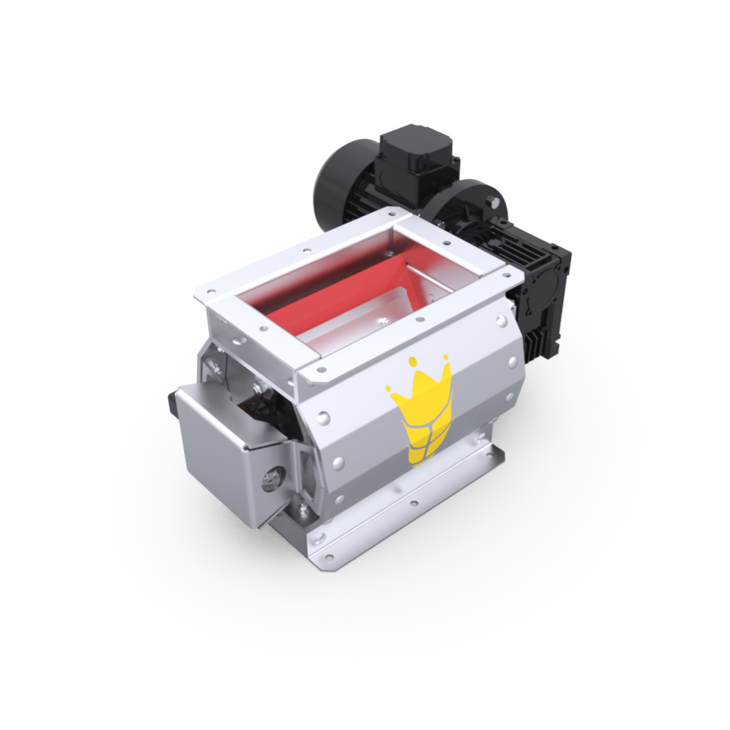

Right-sided screw chamber design | Available | Available |

Right-sided purified air chamber design | Available | Available |