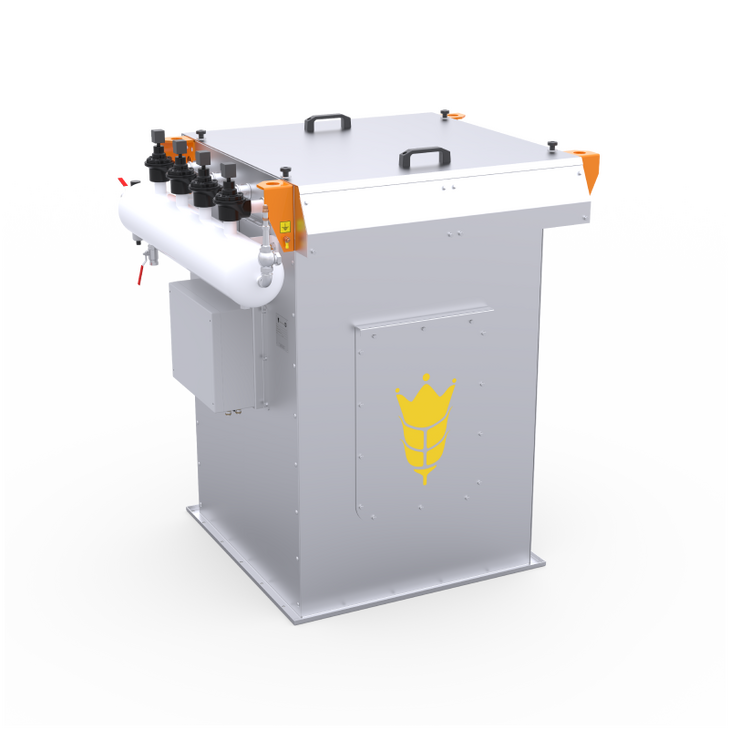

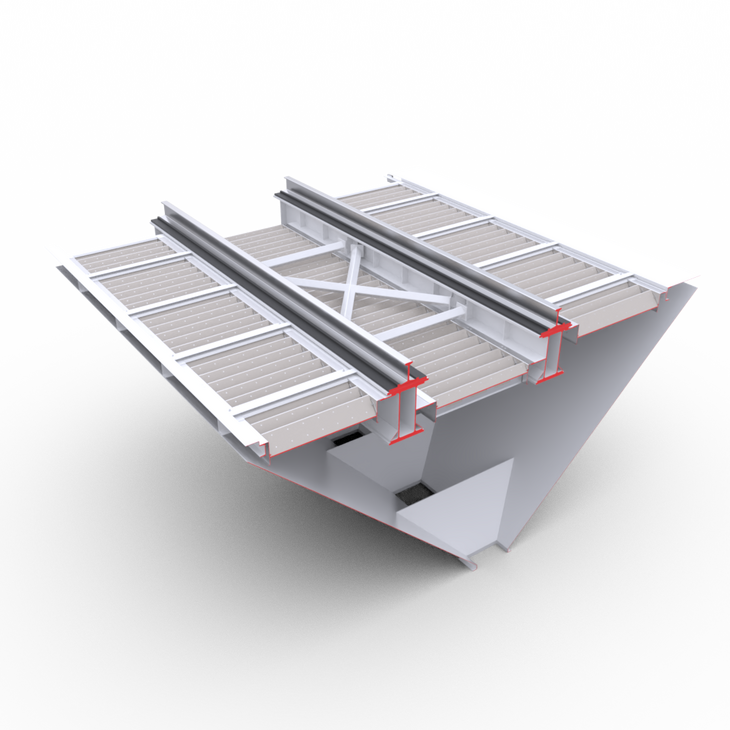

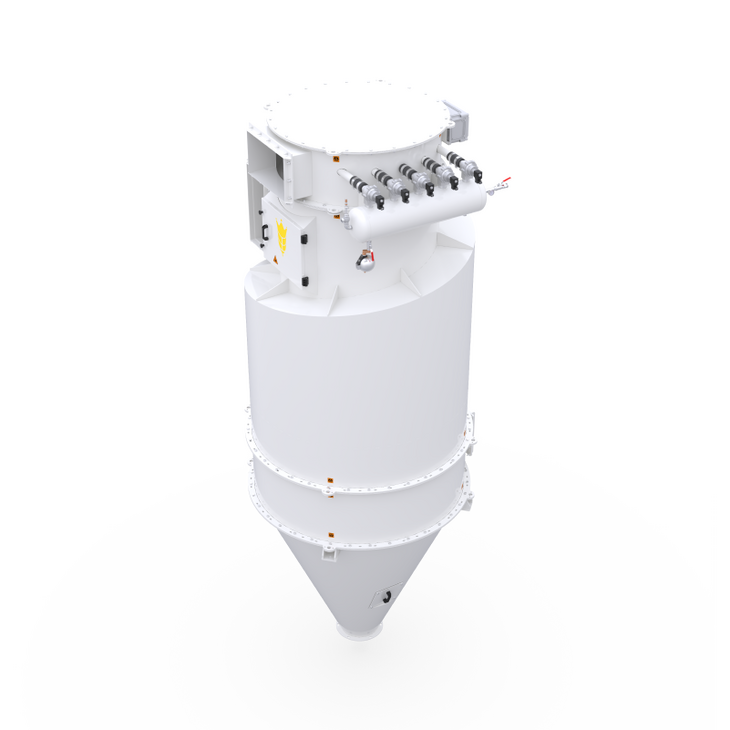

The dusty air generated in the receiving hopper flows into the dusty air chamber, where the dust settles on the filter elements, and the purified air flows into the purified air chamber and is discharged into the atmosphere through an exhaust fan. The dust deposited on the filter elements is returned to the product through a regeneration system (self-cleaning).

- High air purification efficiency of up to 99.6%.

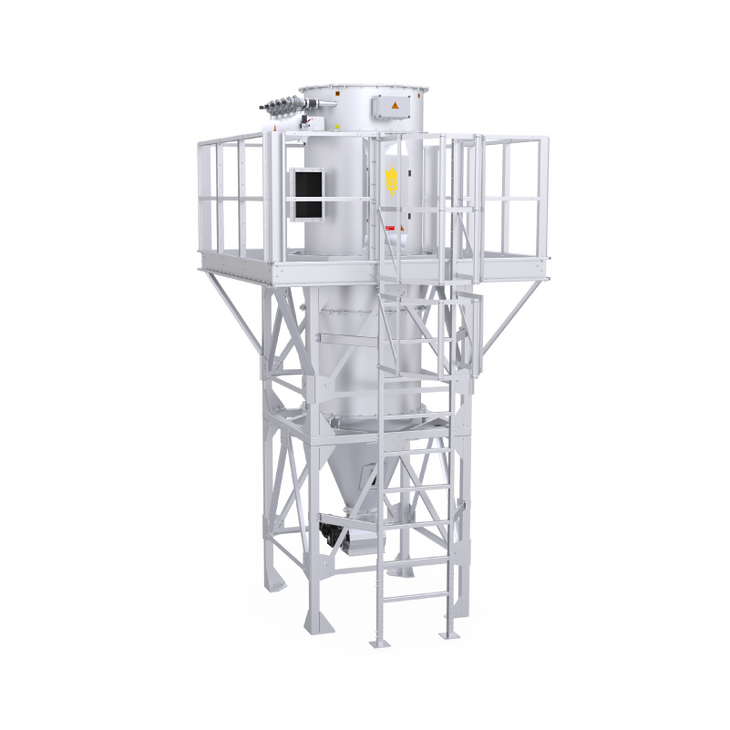

- An option to install on any type of receiving hoppers.

- Higher regeneration rates due to optimized geometric parameters of nozzles and filter elements.

- An option to connect to existing centralized compressed air systems.

- Applying reliable European-made components.

- Applying sleeves made of high-performance filter fabrics based on nanotechnology.

- The filter is easy to assemble and install because the parts are manufactured on high-precision equipment.

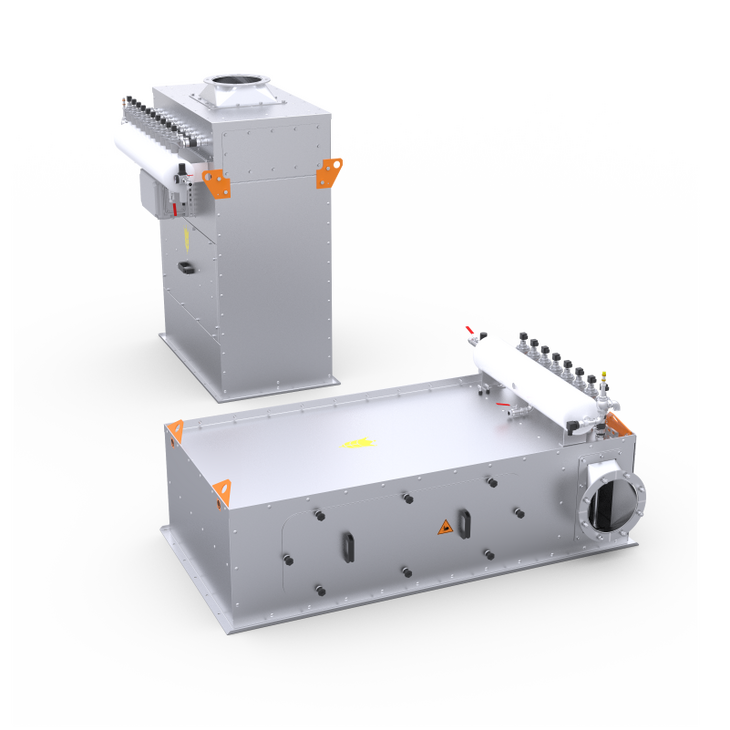

- Compact dimensions and assembly from standard modules.

- Saving the weight of the transported product.

- An option to minimize the compressed air consumption by the filter thanks to a smart regeneration system, which is produced depending on the plant operating conditions.

- Operation at a temperature ranging from -10 to +50 °С (if the air treatment complies with the technical regulations specified in the product data sheet).

- An option to design equipment for operating conditions in ATEX 21 and ATEX 22 zones.

L-series | P-series | |

Warranty, months | 18 | 24 |

Operation mode | Regularly throughout the year | Daily and continuously |

Housing material |

|

|

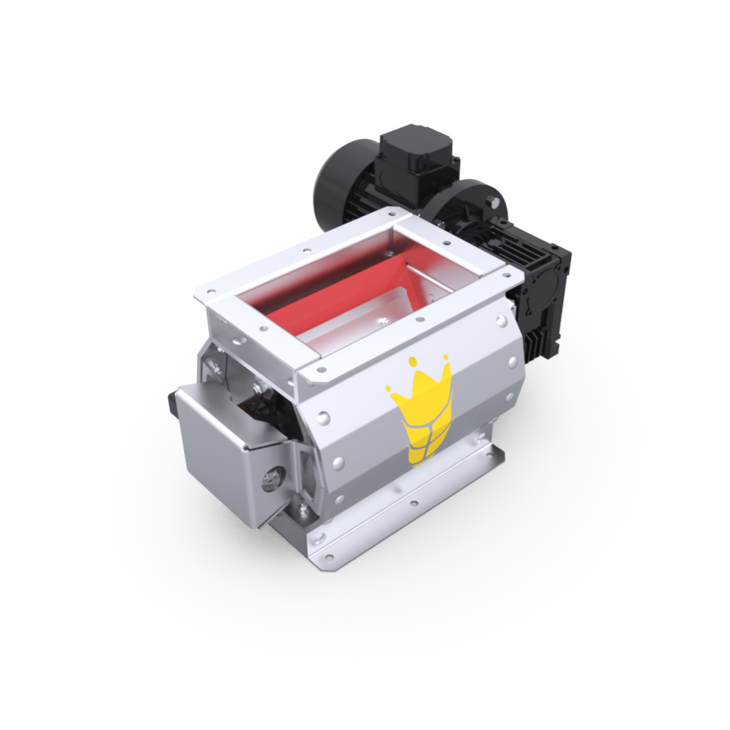

Filter regeneration system | Europe (Camozzi) | Europe (Camozzi) |

Air treatment system | Europe (Camozzi) | Europe (Camozzi) |

Filter element (antistatic, oil and water repellent) | Europe (PES 500) | Europe (PES 500) |

Pressure differential sensor | - | Available |

Pressure sensor | - | Available |

Control unit | IP 56 | IP 66 |

Dusty air intake from the hopper | Available | Available |

Right-sided housing design (receiver on the right, exhaust on the left) | Available | Available |