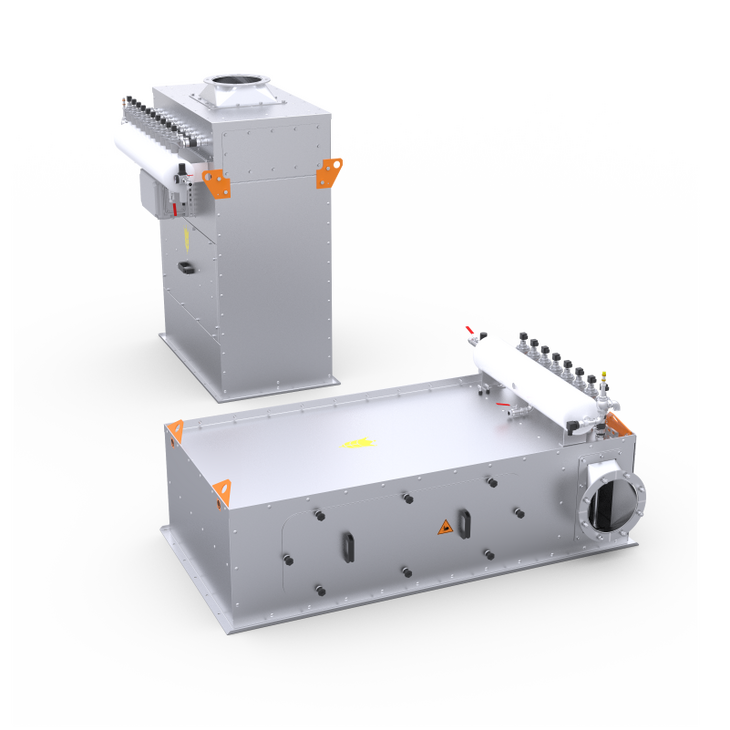

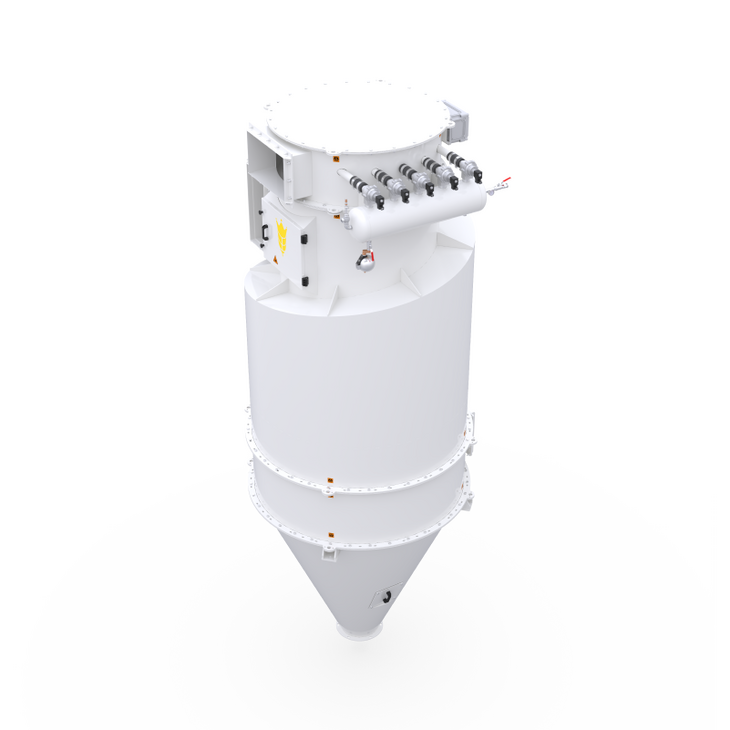

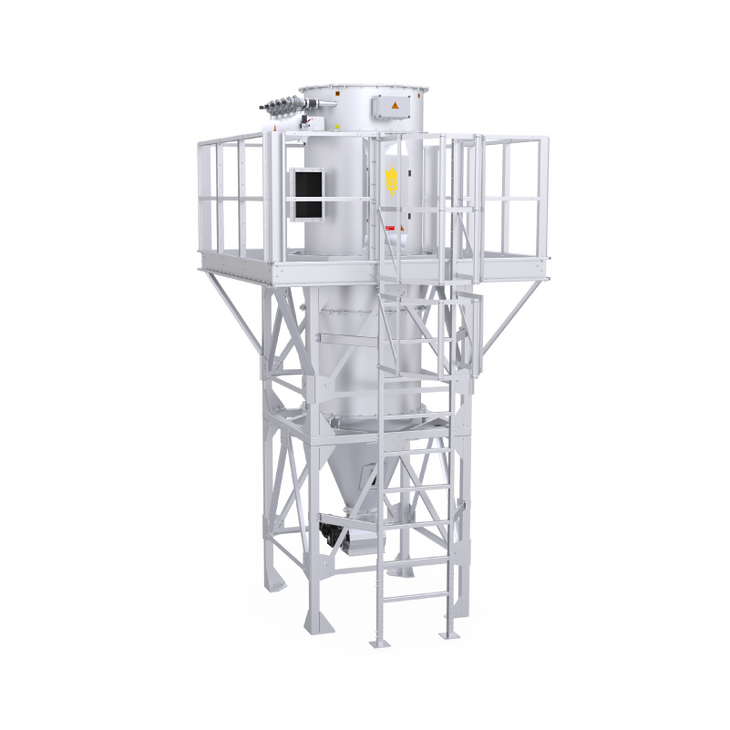

The ZEO-FK cassette type air purification filter is designed to effectively remove dust from process flows in industrial plants. Its design combines the advantages of two systems – cassette and bag – to provide cleaning efficiency of up to 99.6%. This air filter is used in elevators, mills, feed mills and grain processing plants as part of modern aspiration equipment.

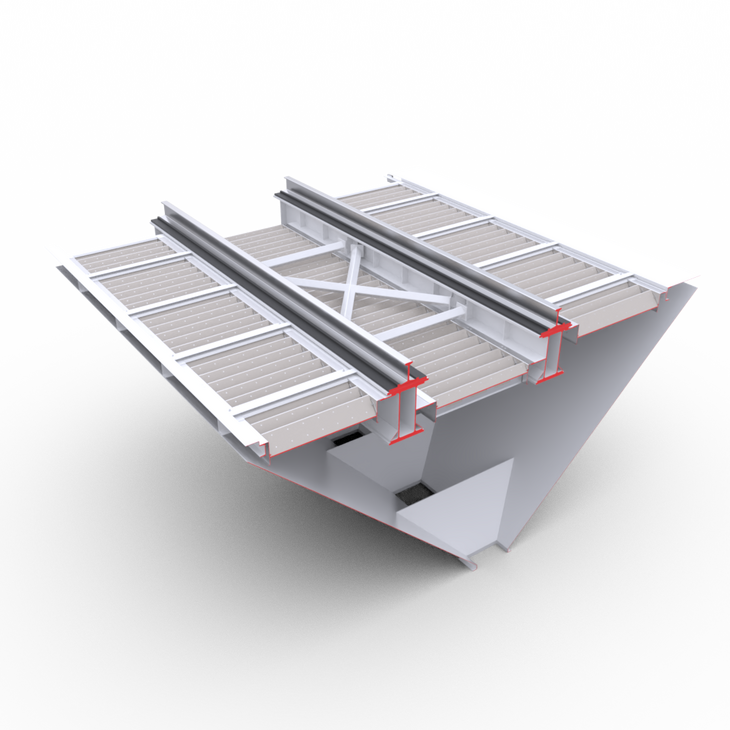

In the ZEO-FK bag filter, dusty air enters the dusty air chamber, passes through the filter elements, where the dust settles on the surface of the cassettes. Already purified air enters the clean air chamber and is discharged into the atmosphere through the exhaust fan. The accumulated dust is directed to the bag filter hopper by the regeneration system and discharged to the waste hopper or returned to the process.

Thanks to their compact design, ZEO-FK bag filters take up minimal space and can be easily integrated into existing elevator equipment. The ZEO-FK cassette filter operates effectively in both local and centralized aspiration systems, providing stable air purification even during intensive production lines.

- High dust removal efficiency of 99.6%.

- The cassette filter can be used both locally and in centralized networks.

- High performance of the cassette filter with relatively small overall dimensions.

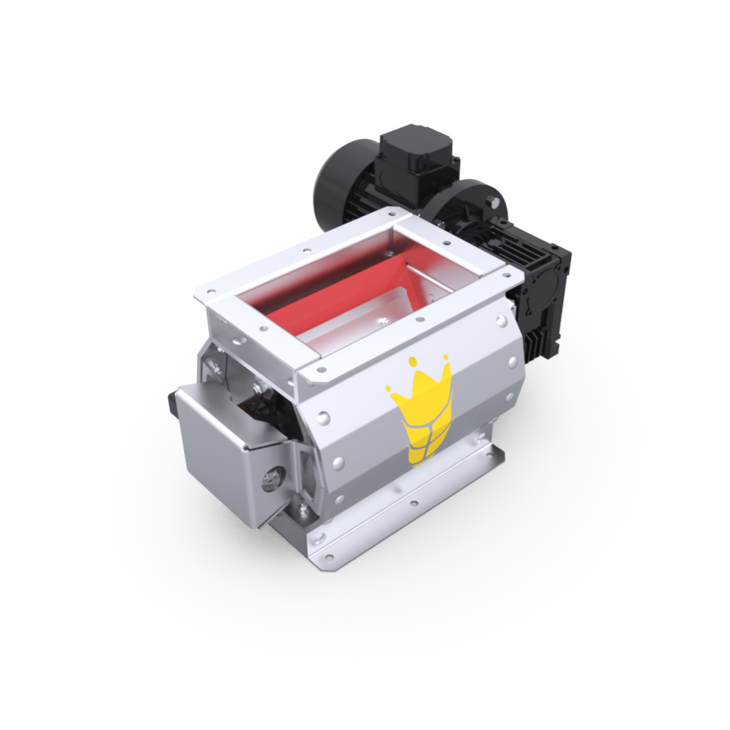

- The equipment is equipped with a dust hopper and an airlock gate.

- Increased regeneration efficiency due to optimally selected geometric parameters of nozzles and filter elements of the bag filter.

- The use of reliable components made in Europe.

- Simple and quick installation, easy maintenance.

- Minimal energy costs.

- Possibility to install the air filter in an open area.

- Operating temperature range from -10 °C to +50 °C (subject to preparation in accordance with the product passport).

- Can be manufactured in a version adapted for use in areas of ATEX 21 and ATEX 22 categories.

L-series | P-series | |

Warranty, months | 18 | 24 |

Operation mode | Regularly throughout the year | Daily and continuously |

Housing material |

|

|

Filter regeneration system | Europe (Camozzi) | Europe (Camozzi) |

Air treatment system | Europe (Camozzi) | Europe (Camozzi) |

Filter element (antistatic, oil and water repellent) | Europe (PES 500) | Europe (PES 500) |

Pressure differential sensor | - | Available |

Pressure sensor | - | Available |

Control unit | IP 56 | IP 66 |