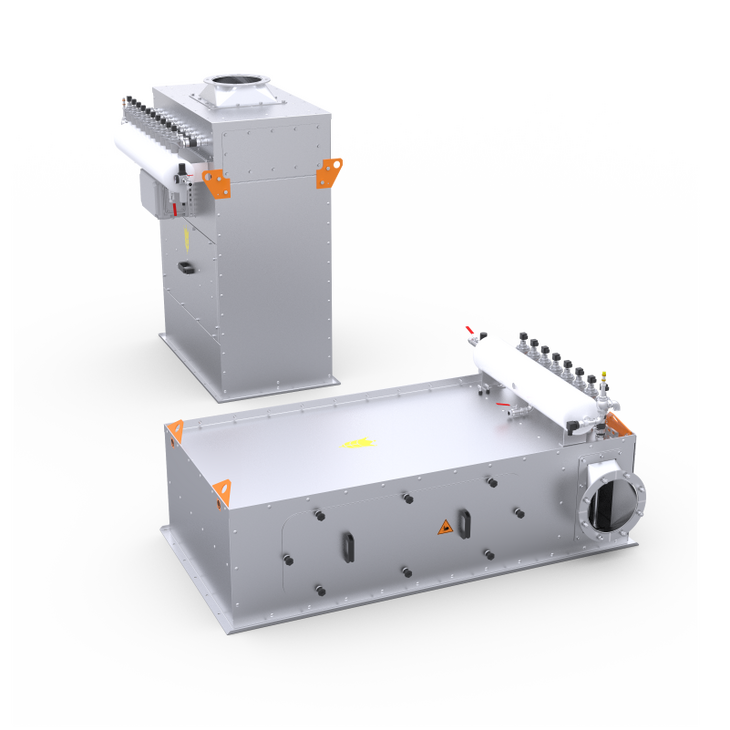

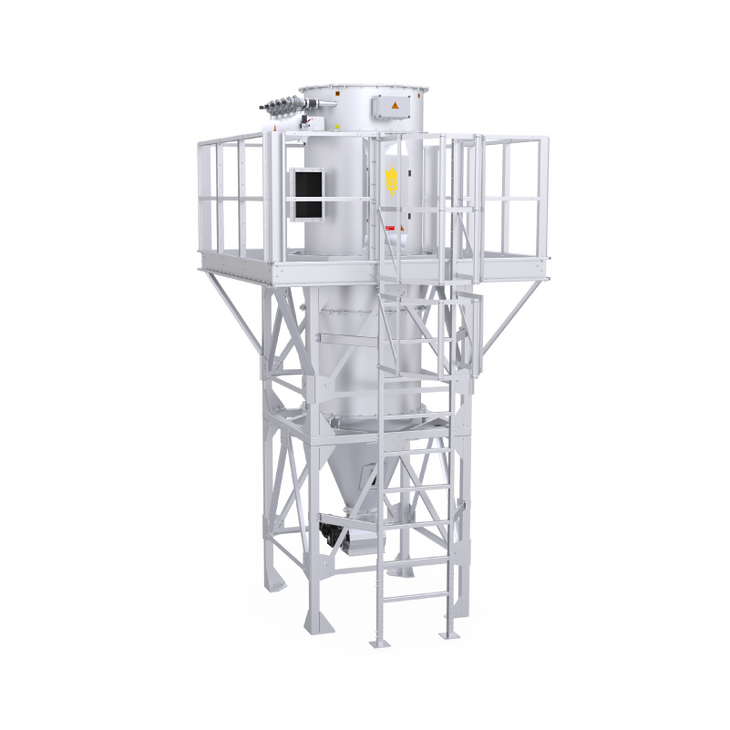

ZEO-VAB Flap System

Add to my project

The FLAP system allows the product to enter the hopper unhindered, but prevents dust from escaping. Dusty air is extracted from the hopper using cabinet-type filters and/or a centralized aspiration network. The use of the system reduces the amount of exhaust air required to keep dust in the hopper, significantly increasing the efficiency of aspiration units.

The ZEO-VAB flap system is part of a modern complex of aspiration equipment, which is used at elevators, grain processing and transportation enterprises. Thanks to the hermetically sealed valve mechanism, it minimizes air losses during hopper loading and ensures effective dust removal. It creates a controlled flow in the loading area, reducing the concentration of dust particles and the load on the air cleaning system. The flap system provides increased resistance to abrasive particles and pressure fluctuations, which allows the equipment to be used in intensive industrial environments. Thanks to its modular design, it can be easily integrated into any elevator equipment.

- The ZEO-VAB flap system is installed on receiving hoppers and on filling pits.

- It is a one-way check valve system. It is located under the lattice ceiling.

- The flap system can be used as an independent unit to provide dust suppression, but it is most effective in combination with other aspiration equipment.

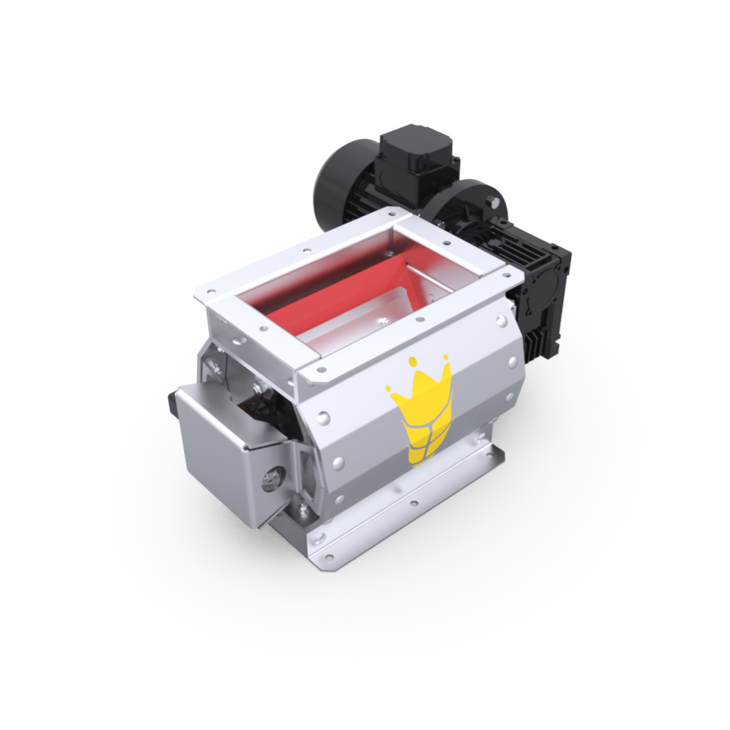

L-series |

P-series |

|

|

Warranty, months |

12 |

12 |

|

Operation mode |

Regularly throughout the year |

Daily and continuously |

|

Housing material |

|

|

|

Valve material |

Steel+PE |

Steel+PE |

|

Skirting material |

Steel |

Galvanized steel + PE |

|

Coating |

Polyurethane |

- |

|

RAL |

7015 |

- |

|

Weight 1 m 2 (excluding metal structures), kg |

90 |

90 |