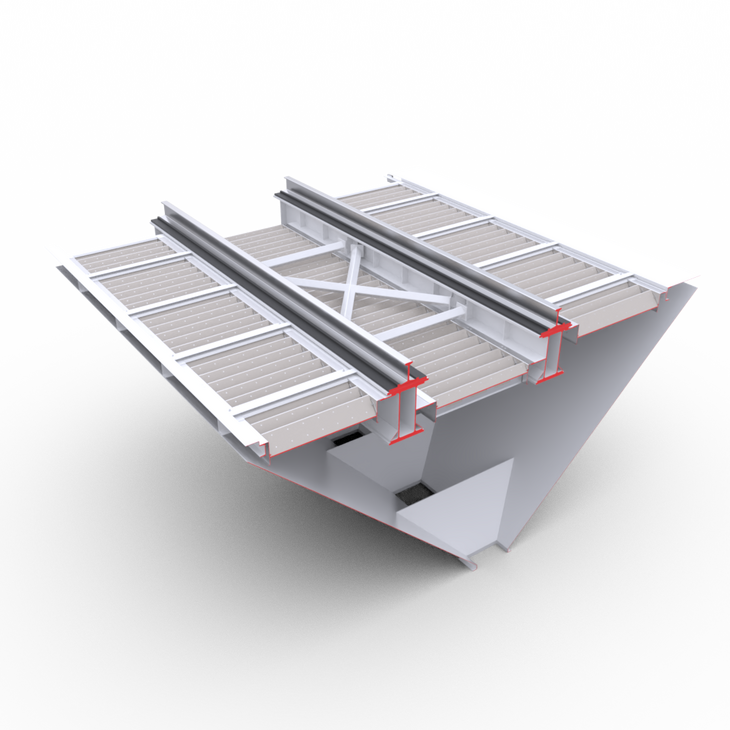

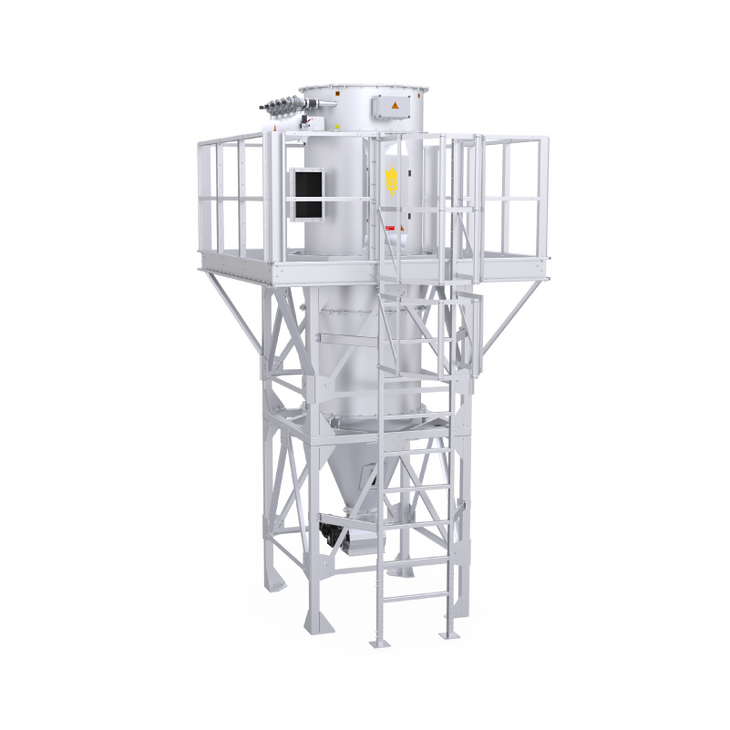

The ZEO-FC cyclone filter is a highly efficient aspiration equipment. Thanks to its two-stage filtration system, it effectively removes up to 99.6 % of dust particles generated during grain transportation and drying. In this cyclone filter, the dusty air is fed through the inlet to the preliminary cleaning stage, which is set in a rotating spiral motion. The dust is pressed against the walls by centrifugal force, loses its speed and rolls down into the collecting cone. After passing the preliminary stage of dust separation (about 75%), the particles thus cleaned enter the second stage of filtration – the fine cleaning chamber, where the filter elements are located. Air penetrates the filter material and enters the chamber already purified. The purified particles are discharged into the atmosphere using an exhaust fan. The dust filtering of the sleeves is carried out automatically by a regeneration system (self-cleaning). The separated dust enters the collecting cone and is discharged back into the process or waste hopper via an airlock gate. The design of the cyclone hopper creates conditions for uniform settling.

The grain cyclone optimizes the operation of elevator equipment, reduces the load on the filter elements and extends their service life. Compared to standard air cleaning cyclones, the ZEO-FC model is characterized by stable performance.

- High efficiency of the cyclone filter – 99.6%.

- The use of sleeves made of high-performance filter fabrics manufactured using nanotechnology.

- Increased regeneration efficiency due to optimally selected geometric parameters of nozzles and filter elements.

- The use of reliable components from leading global manufacturers.

- The design combines two stages of cleaning and does not require the installation of an additional dust collector, which reduces the load on the filter sleeves and extends their service life.

- Simple and quick installation, easy maintenance.

- Operation at a temperature range from -10°C to +50°C (subject to compliance with the technical regulations specified in the product passport).

- The FC can be installed instead of existing dust separation devices.

- Effective dedusting due to the preliminary separation of heavy and large dust particles, as a result of the dust-air mixture intake along a spiral trajectory.

- The filter can be installed in an open area.

- Completion of filtering plants with self-supporting service platforms.

- Possibility of making mechanisms for operating conditions in the ATEX 21; ATEX 22 zone.

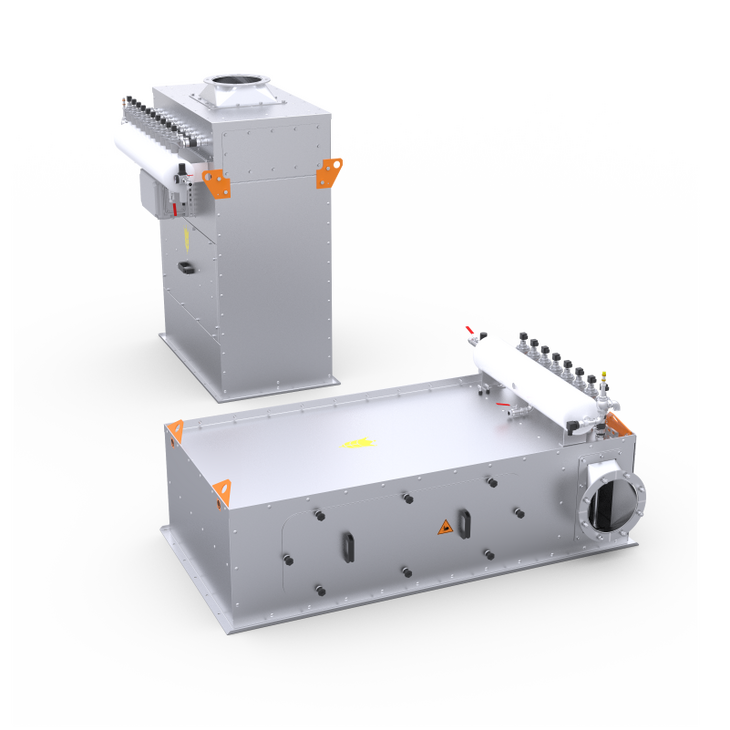

L-series | P-series | |

Warranty, months | 18 | 24 |

Operation mode | Regularly throughout the year | Daily and continuously |

Housing material |

|

|

Filter regeneration system | Europe (Camozzi) | Europe (Camozzi) |

Air treatment system | Europe (Camozzi) | Europe (Camozzi) |

Filter element (antistatic, oil and water repellent) | Europe (PES 500) | Europe (PES 500) |

Pressure differential sensor | - | Available |

Pressure sensor | - | Available |

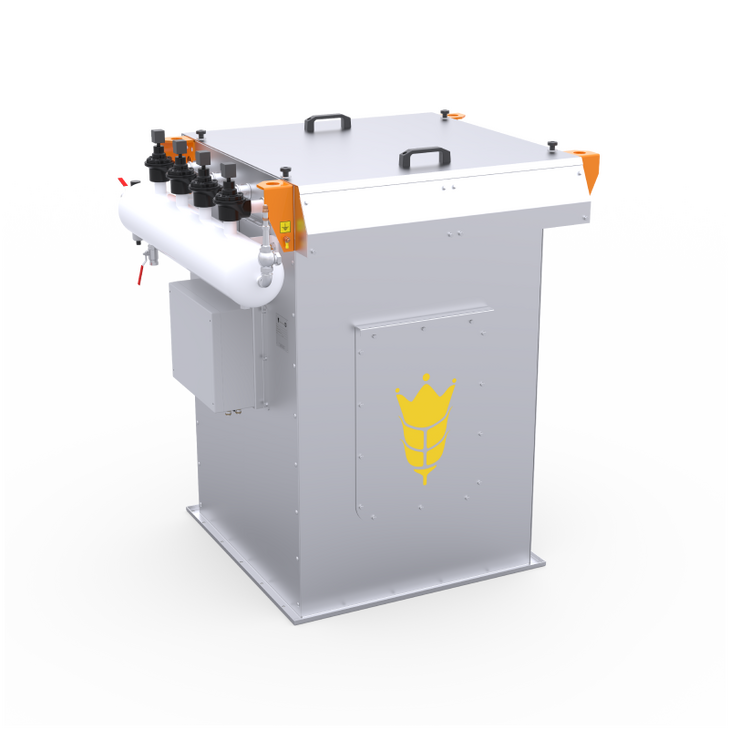

Control unit | IP 56 | IP 66 |

Coating | Polyurethane | Polyurethane |

RAL | 7015 | 5010 |

Right-sided screw chamber design | Available | Available |

Right-sided purified air chamber design (receiver to the right of the exhaust) | Available | Available |