Competitive grain terminal: energy efficiency comes first

Ukrainian grain industry: development and challenges

In modern conditions, against the background of a complex geopolitical situation and military actions, the main grain flows are directed to marine terminals of high productivity, technology, reliability and safety with optimal transshipment costs. Despite the hostilities, Ukraine's agricultural sector continues to function, albeit with certain challenges and difficulties. According to the Ministry of Agrarian Policy and Food of Ukraine, grain exports in 2024 amounted to about 50 million tons, which indicates the sustainability and adaptability of the industry to new conditions.

Odessa National Technological University together with Grain Capital successfully conducted a system analysis of the entire network of technological processes of grain receiving, processing, storage and shipment in order to ensure maximum quality of grain materials at the lowest possible energy costs. The issues of reducing environmental pollution and ensuring environmental safety were also addressed. In the context of the war, these aspects are of particular importance, as the agricultural sector remains one of the key sectors in the Ukrainian economy, providing for both domestic needs and export supplies.

Commodity quality of grain

Various studies and many years of experience in the development of major transportation and technological lines have identified key factors affecting the deterioration of grain quality. Among the important aspects of preserving grain quality is its traumatization, especially relevant is the issue of corn crushing.

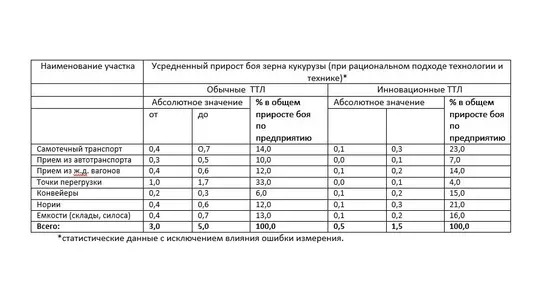

According to the analysis of Ukrainian grain enterprises, the increase in corn crushing is:

- 4.0-6.5% for rigid modes of operation of transportation and technological lines (TTL) of 1980-1990s;

- 2.0-4.0% for transshipment elevators with TTLs using modern high-capacity equipment (500-1500 t/h).

These losses are often attributed to non-compliance with process rules, in particular:

- Crushing of grain by traction bodies;

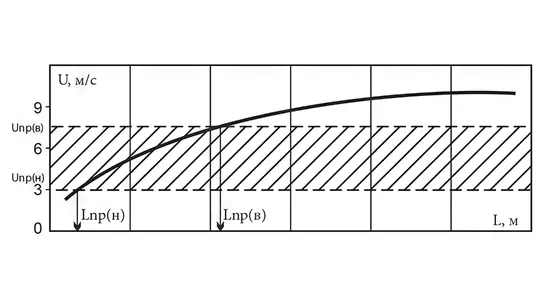

- Lack of synchronization of speed modes of loading, unloading and movement of grain streams;

- Impulsive nature of peak loads on the traction body and drive mechanisms.

Our studies have shown that the reduction of crushed grain gain is achieved by an integrated approach including:

- Drying of grain with optimal intensity (not more than 5% in one pass);

- reducing the length of transportation routes;

- Application of technical means that reduce the speed of impact of grain on the working bodies;

- Minimizing the use of chain conveyors and elevators in TTL;

- Application of grain velocity dampers in gravity drains and silos;

- Soft speed modes of movement of belts, chains and buckets;

- Optimal geometry of loading and unloading units of elevators, discharge chutes and conveyor boxes.

Elevator energy efficiency

To reduce the energy intensity of marine grain terminals, energy audits were conducted at several terminals in Odessa, Chernomorsk and Nikolaev. The audit results showed significant opportunities to reduce energy consumption. According to the energy efficiency level, the enterprises were divided into three groups:

- E3 - high level of energy efficiency (less than 1.5 kWh/t);

- E2 - medium level of energy efficiency (1.5-3.5 kWh/t);

- E1 - low energy efficiency level (more than 3.5 kWh/t).

Achieving E3 energy efficiency requires a two-step approach: during the design phase and during operation. Design involves efficient planning of equipment layout, minimization of route lengths and use of energy efficient equipment. Operational energy efficiency is achieved through a high quality automation system (UAS). The ADAS provides complete process control and synchronization, including:

- Full control of grain movement routes within the elevator;

- Synchronization of receipt and shipment from road, rail and sea transport;

- Control of conveyors, gates, valves and distributors;

- Monitoring and operational data collection on the condition of all equipment;

- Diagnostics of accidents and deviations from the technological process;

- Prevention of unauthorized stoppage of equipment;

- Monitoring of motor loads and prevention of emergency situations.

The use of distributed input/output devices "Siemens" or "Phoenix Contact" can reduce the cost of cable products by up to 30%. Fiber-optic communication lines using ProfiNet protocol are widely used for communication between automated devices. The control system is built according to the server-client structure, which allows to increase the reliability of operation and simplifies the process of system modernization.

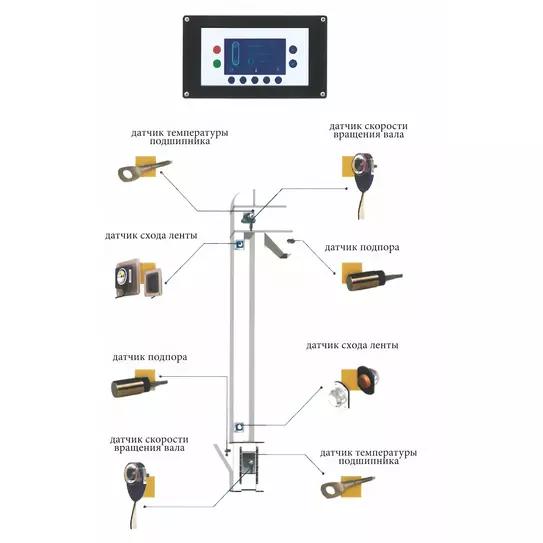

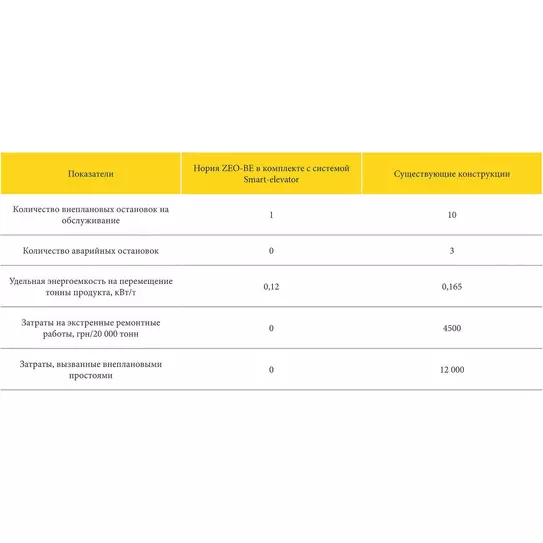

Reliability is a critical indicator that is defined by uptime, durability and maintainability. Ensuring grain terminal reliability is achieved through equipment reliability and effective diagnostic methods. This is helped by the Smart-Elevator system, which provides:

- Control of the technical condition of the main components of the equipment;

- Control and quality management of the transportation process;

- Optimization of energy consumption;

- Planning of routine maintenance and repair of equipment.

Safety

The increasing requirements of environmental services and the problems of explosion hazards of dust-air mixtures require new dust extraction systems. In collaboration with ONTU and Grain Capital, a three-tiered environmental safety system was developed that includes:

- Suppression of dust extraction sources;

- Sealing and stabilization of dust extraction sources parameters;

- creation of new locally distributed dust extraction control systems.

- Dust removal complex based on SMART-system of "smart" aspiration units provides dust suppression efficiency up to 99%, reducing energy consumption by 1.5-3 times. This allows complete control of air dustiness in production facilities, preventing the spread of dust into the environment.

Conclusions

To summarize, it is worth noting the importance of achieving an optimal balance between the following parameters:

- Throughput capacity of technological lines;

- Compliance of product quality with export standards;

- Energy efficiency per ton of grain;

- Environmental safety and explosion protection;

- Reliability of technological equipment.

- Achieving this balance helps to reduce the payback period of investments and determines the prospects for the development of marine grain terminals in Ukraine.

Authors:

A.I. Gaponyuk, Professor, Doctor of Technical Sciences, Head of the Department of Technological Equipment and Aspiration of Grain Production at ONTU, Grain Capital.

I.A. Gaponyuk, Grain Capital Development Director.