Triad of grain terminal efficiency

Gaponyuk Oleg Ivanovich, Professor, Doctor of Technical Sciences, Head of the Department of "Technological Equipment of Grain Production" at Odessa National Technological University (ONTU), CEO of Grain Capital, together with Ovsyannikov Yuriy Ivanovich, Candidate of Technical Sciences, Associate Professor at ONMU, Deputy Director of Novotech-Terminal LLC, published an article - "Triad of grain terminal efficiency" (Ports of Ukraine No. 10, December 2017), based on the joint experience of building an efficient grain terminal in Odessa Sea Port.

The near future of the grain transshipment services market is determined by the commissioning of a significant number of new high-capacity grain terminals. In conditions of growing competition, the success of an enterprise will depend on the efficiency of its operation. However, terminal efficiency is not determined only by large storage volumes or high performance. It depends on interrelated indicators that are aligned with the strategic objectives of the terminal and take into account the business strategies of the owners.

Traditional design and construction of grain terminals focuses on the realization of the basic parameters laid down in the technical specification. This usually concerns annual cargo turnover, storage volumes and cargo flow patterns, as well as vehicle characteristics and grain storage requirements. All these parameters are superimposed on the existing infrastructure and terminal area. However, providing these parameters does not guarantee a truly efficient terminal.

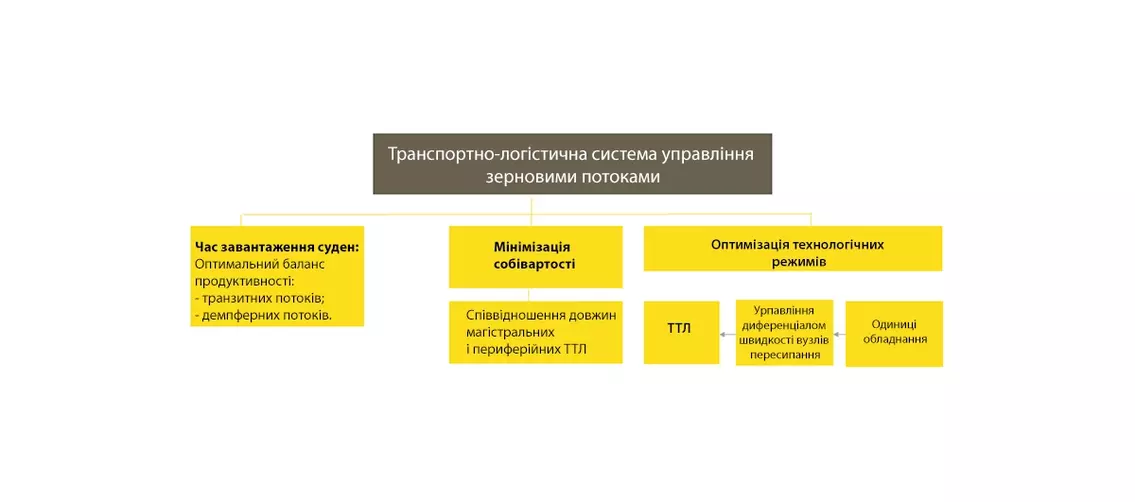

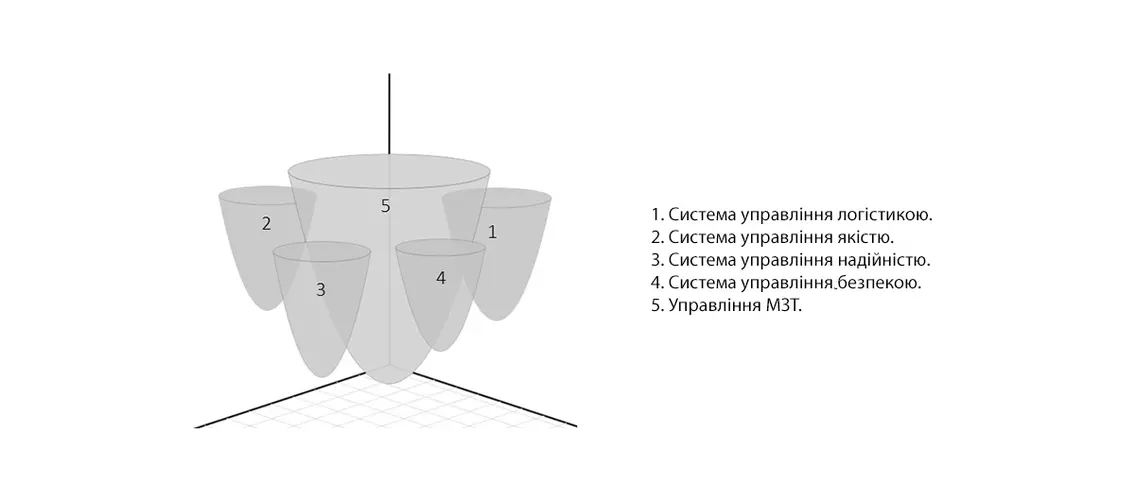

An efficient grain terminal can be described as a triune system consisting of: efficient design, efficient management system and efficient adaptation to market conditions. This is achieved through a rational combination of key indicators such as vessel loading time, cost of operations, reliability and safety. Optimization of these indicators should be based on performance criteria appropriate to the business model being implemented.

For different terminals, the set of indicators may vary depending on strategic goals. For example, one terminal may prioritize energy efficiency, while another may prioritize cargo handling speed. However, the common performance criteria remain the quality of grain handled, energy efficiency, reliability and environmental performance.

Energy efficiency is one of the key characteristics of grain terminals and is determined by the energy consumption for transshipment of one ton of grain. Studies of terminals in the ports of Odessa, Chernomorsk and Nikolaev have shown that most of them fall into three categories in terms of energy efficiency: high (less than 1.5 kWh/t), medium (1.5-4.5 kWh/t) and low (more than 4.5 kWh/t).

Achieving a high level of energy efficiency requires an integrated approach from design to operation. This includes optimizing equipment layout, minimizing transportation routes, using energy-efficient technologies and implementing automated control systems. Modern automation systems for grain terminals should provide full control and monitoring of all processes: from grain movement to the condition of equipment and aspiration systems.

In addition, the efficiency of a grain terminal is also determined by its ability to ensure grain quality during transshipment. This includes controlling the moisture content, purity, integrity of the grain and preventing pest infestation. The quality management system must ensure that these parameters are maintained at all stages of the technological process.

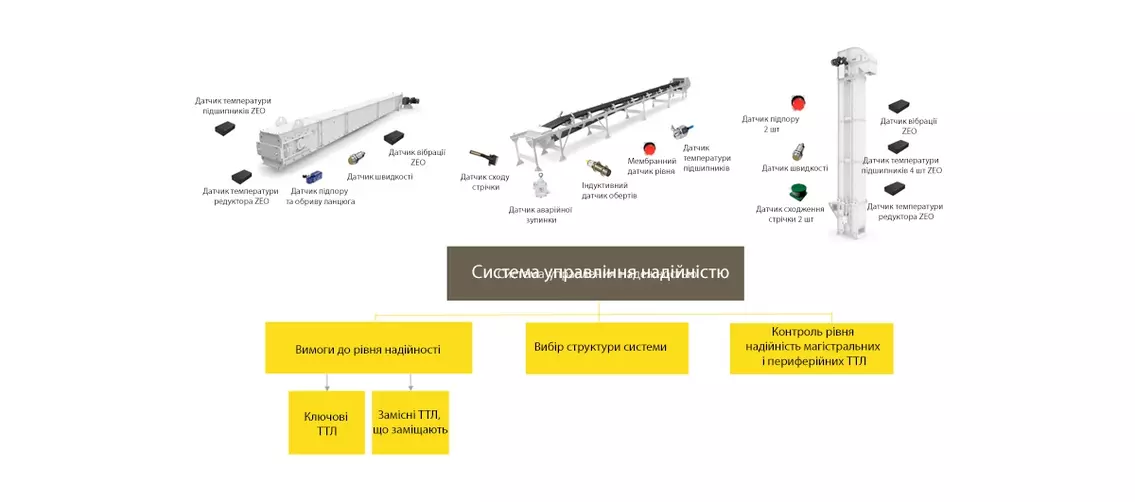

Terminal reliability is another important criterion, characterized by equipment uptime, availability and technical utilization. The reliability management system should include monitoring the technical condition of the equipment, planning and carrying out routine maintenance and repair work, as well as prompt response to possible deviations from the normal operating mode.

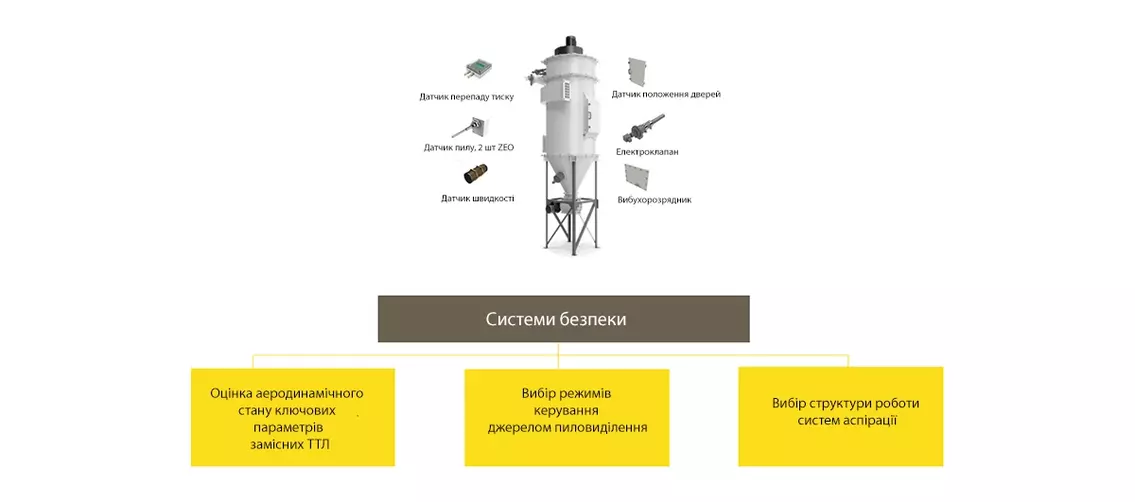

Environmental safety management is aimed at reducing the environmental impact of the terminal's operations. This is achieved through the introduction of new-generation aspiration systems, which ensure efficient air purification from dust and prevent emissions of harmful substances into the atmosphere. The introduction of a three-level environmental protection system helps minimize environmental impact and ensure safe operation of the terminal.

Optimizing terminal operations requires a systematic approach, which includes the development and implementation of an integrated management system. Such a system should combine logistics, quality, reliability and safety management into a single complex that will maximize the efficiency of the grain terminal's operation.

Thus, the introduction of modern technologies and innovative management approaches will allow grain terminals not only to increase their efficiency but also to ensure their competitiveness in the global market. This will not only contribute to the development of individual terminals, but will also ensure the growth of Ukraine's grain sector as a whole.