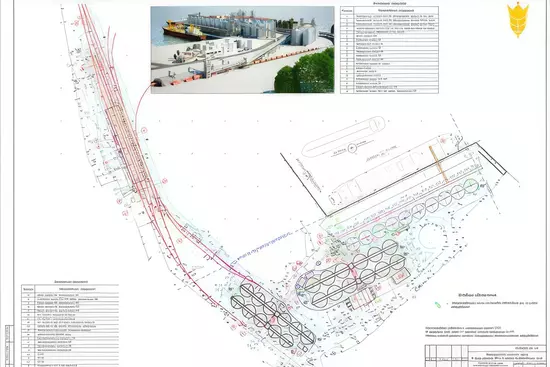

Grain handling complex of Brooklyn-Kyiv LLC

When designing the Brooklyn-Kyiv grain handling complex, for the first time the task was set to build a new generation enterprise that would meet the highest energy, technological and international environmental requirements.

Transshipment complex

Primary goal:

Ensuring additional cargo turnover of the Odessa seaport by 2.5...5 million tons of bulk cargo per year.

Scope of work:

The project for the construction of a grain transshipment complex with a capacity of 235 thousand tons of simultaneous storage of grain provides for:

- Granary No. 1 with a total capacity of 66 thousand tons of grain, consisting of 11 metal silos with a diameter of 19.86 m with a capacity of 6 thousand tons each. All silos are equipped with thermometry systems. An aeration system is installed in four silos.

- Granary No. 2 with a total capacity of 109 thousand tons of grain, consisting of 12 metal silos with a diameter of 22.15 m. Capacity of 9 thousand tons each. All silos are equipped with thermometry systems. An aeration system is installed in four silos.

- Granary No. 3 with a total capacity of 60 thousand tons. grain, intended for the formation of homogeneous batches of grain, short-term storage and their shipment to water transport. Includes 10 metal silos with a diameter of 19.86 m and a capacity of 6 thousand tons each. All silos are equipped with thermometry systems. Aeration systems are installed in two silos.

Grain intake:

From road transport, three auto-unloaders with a capacity of 80 tons. Each, consisting of two receiving streams with a capacity of 500 tons/hour each.

By rail, there are two railway tracks with 8 cars each. Unloading of railway cars is organized in two streams with a capacity of 500 t/h each.

Grain release:

For water transport, it is produced by a technological line consisting of hopper scales of 1500 t/h, a release conveyor of 1500 t/h, a ship-loading machine, gravity and aspiration equipment.

In containers produced by the technological line, consisting of two release bunkers with a capacity of 50 tons each, two bunker scales with a capacity of 120 t/h, two elevators with a passport capacity of 120 t/h and two stuffing loading pipes with a productivity of up to 120 t/h.

Quantitative accounting of grain:

Incoming railway transport using electromechanical railway scales with a capacity of up to 100 tons.

Incoming road transport using electromechanical vehicle scales with a capacity of up to 80 tons.

Qualitative grain accounting:

Taken from railway cars, it is provided in the laboratory for sighting the railway section. Sampling is carried out using hand probes, for which visual platforms with folding bridges are designed.

Accepted from road transport, it is provided by an imaging laboratory installed on a two-passage vehicle lift. Sampling is provided using automatic samplers; four samplers are installed for this purpose. It is also possible to take samples from vehicles using hand probes; for this purpose, visual platforms with folding bridges are arranged.

Dust removal (aspiration) system for technological and transport equipment:

In places of possible dust formation, local filters, filter cabinets are installed, and dust-proof shelters are installed on conveyor belts. On the section of the steel reception road, 8 centralized aspiration networks are provided.

Grain reloading device

Name of the project:

A device for reloading grain with reference to the composition of raw sugar. New construction.

Project characteristics:

Adaptation of storage capacity to modern market conditions. Replacement of irrelevant storage of raw sugar.

Container stuffing unit

Primary goal:

Improving the transport infrastructure of the enterprise by introducing a point for loading grain into containers.

Scope of work:

This project provides for the installation of a unit for loading grain crops into containers with the possibility of weighing grain in the stream and controlled weighing of vehicles.

Transportation is carried out using elevators, chain conveyors, and gravity devices. Weighing of grain in the flow is carried out by a weighing dispenser, and for road transport - by truck scales. A metal silo hopper is used to accumulate grain. Loading of grain is carried out by a stuffing loader with an aspiration system.

Customer comment

Implementation period:

year 2012