Centralized Aspiration

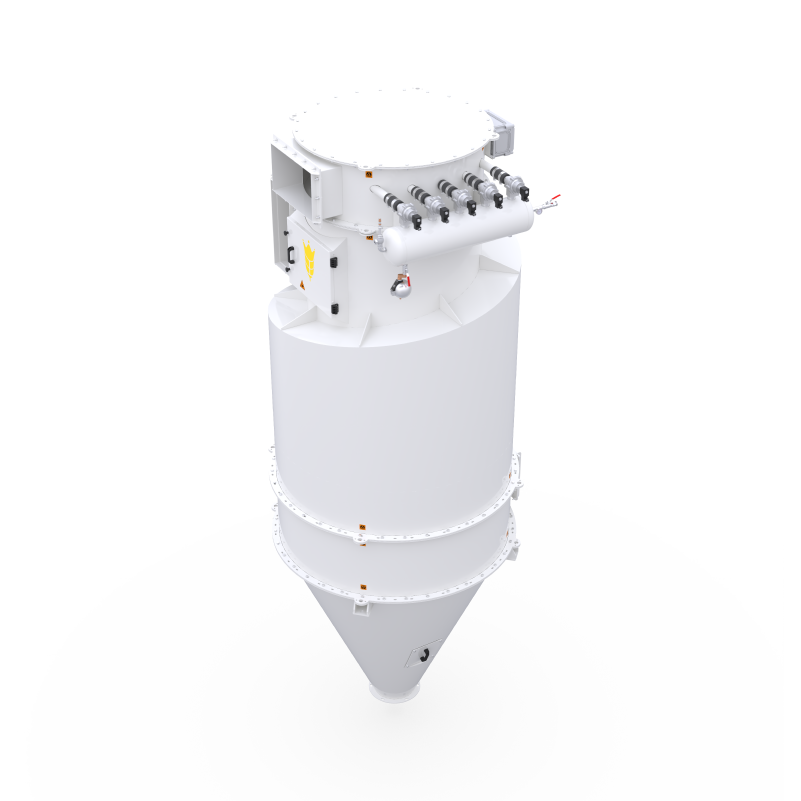

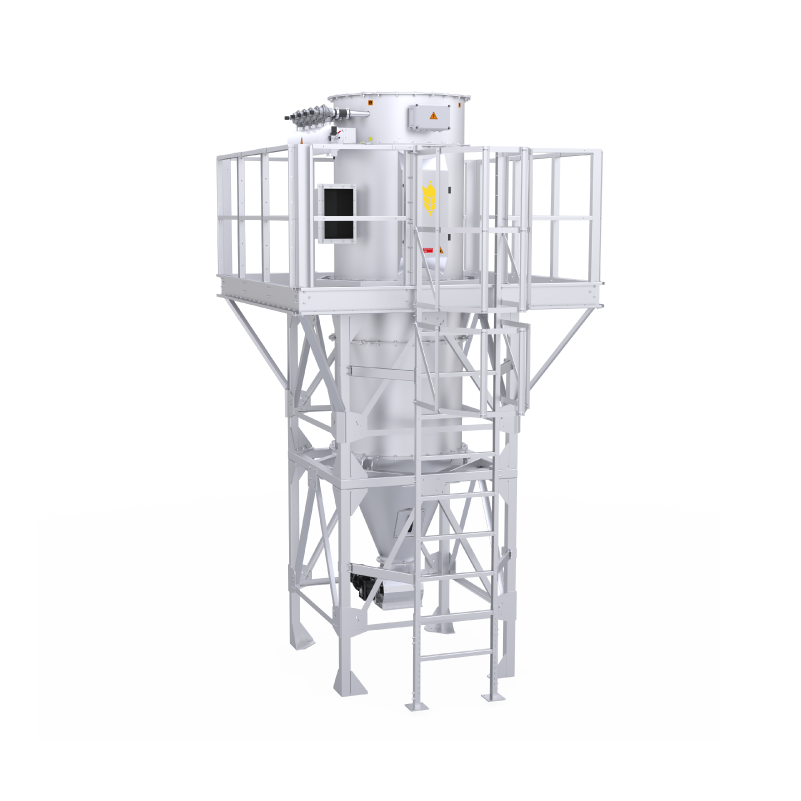

The dusty air flows through the inlet tube to the preliminary cleaning stage of the cyclone filter, gaining a rotational spiral motion. Under centrifugal force, the dust particles are pressed against the walls, losing speed and rolling down into the collecting cone.

The tangential inlet directs the inlet flow along the forming surface of the cylindrical filter housing. Such an injection generates a rotational motion of the dust-air mixture and the particles are exposed to centrifugal and inertial forces. Coarse particles of the mixture lose their velocity and roll down into the collecting cone. The remaining fine dust is fed to the second cleaning stage, i.e. the filter elements.

The dusty air flows through the inlet tube to the dusty air chamber, passing through the filter elements. The dust is deposited on the filter elements, and the air flows into the purified air chamber and is discharged into the atmosphere through the exhaust fan. The dust deposited on the filter elements is fed into the dust extraction hopper through the regeneration system. The dust is discharged from the hopper to the waste hopper or the technological flow through an outlet unit.

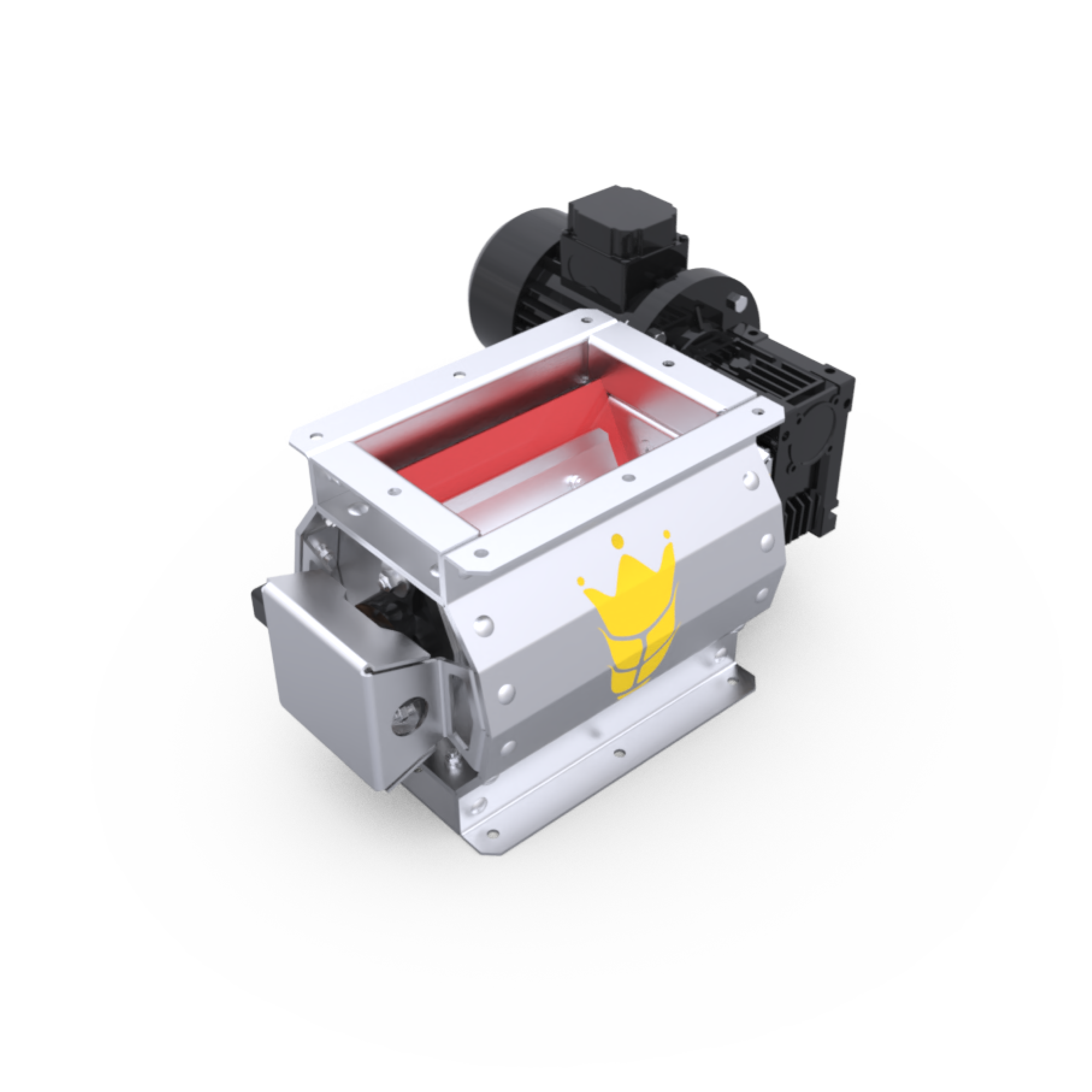

This system is intended for discharging the collected dust from dust separators and operates in dust collecting devices where the pressure is higher than the atmospheric pressure. The air lock is intended for discharging the collected dust from dust separators (both centrifugal and filter), and operates in both discharge and injection systems. Its main purpose (work objective) is to remove the separated dust particles from the dust collecting equipment and prevent air suction.

Questions you may have?