Experience in creating local installations

Experience in the development of localized dedusting plants

Due to the strengthening of environmental standards in the agricultural industry, there is a need not only to modernize transport and technological lines at grain storage and processing enterprises, but also to improve their dedusting systems. Today special attention is paid to local aspiration systems. However, the full utilization of the potential of these units is limited due to the lack of methods for their design. This leads to the fact that local filter modules do not always achieve the declared energy consumption indicators and do not meet the standards of maximum permissible concentrations (MPC) in the premises of grain processing plants.

Production and Research Complex ONTU together with Grain Capital developed a methodology for selecting the type and modes of operation of dedusting systems for typical technological routes of grain movement. This methodology is based on the program for calculating the intensity of dust emission from various sources of dust formation (Lit. 1.2)

Methodology of calculation and selection of local aspiration systems

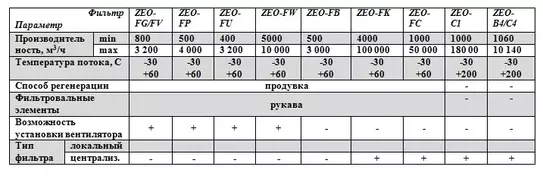

Calculation and selection of local aspiration systems is carried out step by step. An important factor in the efficiency of such installations is the correct choice of filter. The main criteria for filter selection, besides its purpose and capacity, are the dustiness of the air to be cleaned, its temperature, dust characteristics and the method of filter element regeneration. The main parameters allowing to determine the filter type are given in the corresponding table.

It is also necessary to consider the process conditions under which the filter will operate. The choice of filter type depends on the type of transport and process line, and the filter size is determined by the volume of air to be cleaned. The volume of air that is sucked into the filter is also taken into account.

Example of modernization of dedusting systems at Prosyansky grain elevator

The efficiency and potential of Grain Capital's FW, FB, FP, FG, FC, FK series of local units was demonstrated during the modernization of aspiration systems at Suntrade's Prosyansky grain elevator. The experience showed that old generation dedusting units had low efficiency or were practically unusable.

The main problems of centralized aspiration plants were:

- High energy intensity (efficiency 25-45%);

- Low efficiency of dust suppression (50-60% efficiency) and air cleaning (60-70%);

- Significant dustiness of working premises exceeding MPC norms;

- Environmental pollution by dust emissions in the amount of 60-100 tons per year;

- Low reliability due to the long length of ducts and their clogging by dust.

The reconstruction project at Prosyansky elevator envisaged the use of localized dedusting systems adapted to the sources of dust generation at the enterprise. The principle of operation of such systems is to install dust collection equipment directly at the source of dust. Local aspiration filter performs the function of both dust receiver and dust cleaning element, ensuring the return of separated dust back to the grain route without loss of total grain weight.

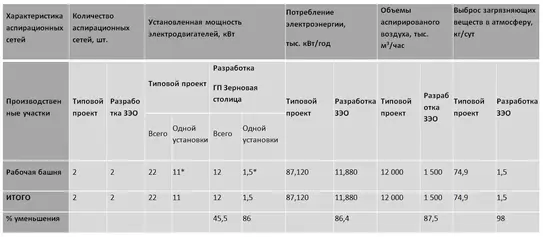

The use of localized units made it possible to create effective rarefaction on large surfaces of ejected dust-air mixtures, which guaranteed dust muffling, which was difficult to achieve with standard dust collectors. The table below summarizes the comparative characteristics of the new dust suppression systems.

Despite all the positive aspects of local aspiration, the main difficulty remains the synchronization of its operation modes with the characteristics of dust generation sources.

Development of "smart" aspiration units of the 4th generation

Within the framework of the technical assignment for modernization of dedusting systems at Prosyanskiy elevator, ONTU production and research complex and Grain Capital developed "smart" aspiration units of the 4th generation. These units provide dust suppression with minimal energy consumption, eliminate environmental pollution, meet environmental standards and explosion safety requirements.

"Smart" aspiration systems automatically respond to changes in transport line capacity, the type of material being moved and the tightness of the equipment, ensuring high operational efficiency.

The software control unit developed in cooperation with Grain Capital's automation department has significantly improved the reliability of plant operation and the quality of the dedusting process. The results of the dedusting system reconstruction confirm the high efficiency of the new units.

The use of local aspiration allows to significantly reduce energy costs (by 3-10 times compared to traditional systems), increase the service life of aspiration units, avoid dust accumulation in air ducts and eliminate the need to use sluice gates.

The experience of modernization of environmental safety systems shows that the maximum effect from the introduction of modern dedusting systems can be achieved only under the condition of full synchronization of aspiration units operation with dust formation processes.

Literature:

- Gaponyuk A.I., Dmytruk A.A. Meteodologic bases of calculation of aspiration systems of grain processing enterprises and elevators. Review information // Media of IT and bakery products. Ser. Elevator industry. - Moscow; 1991 - 48 p.

- Gaponyuk A.I., Gough A.N. Methodology of creation of systems of dedusting of sea grain terminals // Storage and processing of grain. - 2013, № 5. - с. 35-38.