Experience in creating efficient transportation lines based on chain conveyors

Prospects for the development of the bakery products industry are determined by two main trends: construction of new and technological re-equipment of existing grain processing enterprises. Unfortunately, the majority of feed mills, mills and elevators, in particular those that were built back in the 80s, met modern challenges of grain storage and processing with outdated transportation equipment. Traditional chain conveyors no longer meet the requirements for energy efficiency, reliability, processability and safety.

Need for modernization of transport equipment

Modern requirements for transportation equipment require the development of fundamentally new chain conveyors. The basis for the new ideology of transport system design is a balanced balance between energy efficiency, grain quality preservation, explosion safety, environmental friendliness and other critical aspects.

Multifaceted studies of the causes of low efficiency of existing transportation and technological lines at enterprises for storage and processing of grain, carried out by the Department of "Technological equipment of grain production" Odessa National Technological University (ONTU), allowed to identify the key problems of chain conveyors:

- Crushing of grain by the traction organ and low density of grain flow stacking;

- Lack of synchronization of speed modes of loading, unloading and movement of grain streams;

- High concentration of explosive dust and aerodynamic resistance of air flows.

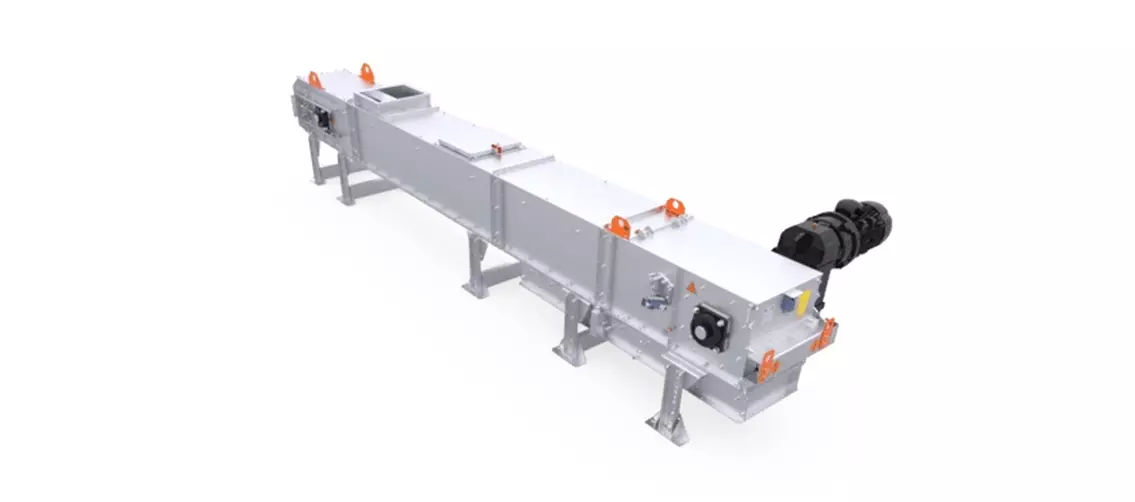

Development of new chain conveyors of ZEO-DC series

Grain Capital addressed these shortcomings in the development of a new line of ZEO-DC series chain conveyors. The development was accomplished in two phases:

Justification of design and mode characteristics: Ensuring the quality of technological processes, in particular reducing the level of grain breakage.

Compliance with modern standards: Requirements for energy efficiency, reliability, environmental and fire safety.

Improvement of transportation sites

Grain transportation speed modes have a significant impact on product quality. Studies have shown that grain in the conveyor box is subjected to shock loads caused by the cyclic jolts of the scraper traction arm. With the new design, Grain Capital eliminated these problems by eliminating direct contact between the traction arm and the housing and reducing the width while increasing the height of the conveyor. This has resulted in a 1.5- to 2-fold reduction in breakage gain.

Chain conveyors are equipped with scrapers made of special elastomeric composite, which provides high strength and durability, as well as reduces the risk of grain damage.

Optimization of loading, unloading and intermediate release

The scraper conveyor loading has also been improved to reduce grain breakage. A system has been developed that prevents product contact with the idle branch of the conveyor, which has reduced grain damage to 0.4% of the total amount of product transported.

The design of the intermediate product outlet device in the new conveyors ensures complete emptying of the box, which eliminates grain accumulation and crushing.

Integration of efficient dedusting systems

One of the priorities in the development of chain conveyors was the development of effective dust suppression systems. Unlike other companies, Grain Capital together with ONTU realized the concept of integrated dust suppression systems adapted to real operating conditions. Thanks to the use of advanced methods and automatic design technologies, it was possible to create customized aspiration units with dust suppression efficiency up to 99.6% and energy efficiency up to 83%.

New standards in design and management

Grain Capital has introduced a new transportation system design ideology that provides customized solutions for specific process lines. This includes taking full account of the varying parameters of grain streams, as well as integrating advanced control systems, such as soft starters for electric motors, which reduce shock loads on grain and extend equipment life.

Results and prospects

Grain Capital's conveying systems significantly increase the efficiency and reliability of elevator equipment. By utilizing the new chain conveyors, you can:

- Increase conveyor efficiency by 10-12%;

- Reduce the increase of grain breakage by 9-11%;

- Increase durability of body parts;

- Ensure stable and uniform operation of transportation lines.

Grain Capital advises on upgrading and renovating transportation lines to reduce maintenance costs, increase productivity and provide a return on investment.

Author of the article: A.I. Gaponyuk Ph.D., Prof. Odessa National Technological University.