Patent for a device to prevent dust generation and dust spreading (Flap system)

In the State Enterprise "Ukrainian Institute of Intellectual Property" was registered patent number 143410 for utility model, developed by our company equipment that prevents dust formation and dust spreading (Flap-system).

Due to application of this device in technological lines of the enterprises, which work with loose cargoes, it is possible to significantly reduce dust emissions into the atmosphere and locally perform cleaning of the atmospheric air of the working zone directly at the workplaces, increase the efficiency of aspiration units, increase the energy efficiency of technological lines and the enterprise as a whole.

Taking into account the experience of the world countries and environmental legislation of Ukraine, the use of this device is simply necessary at every procurement and grain processing enterprise, transshipment complex, etc.

The innovative device developed by GC "Zernovaya Stolitsa" was analyzed, studied and tested the innovativeness of technical solutions applied in our equipment by specialists and experts of the State Enterprise "Ukrainian Institute of Intellectual Property". Based on the analysis, the experts of the State Enterprise "Ukrainian Institute of Intellectual Property" confirmed that the design solutions applied in the construction of Flap-system, the principle of operation and efficiency of our device to prevent the spread of dust has no analogues in Ukraine, which is confirmed by the Patent No. 143410.

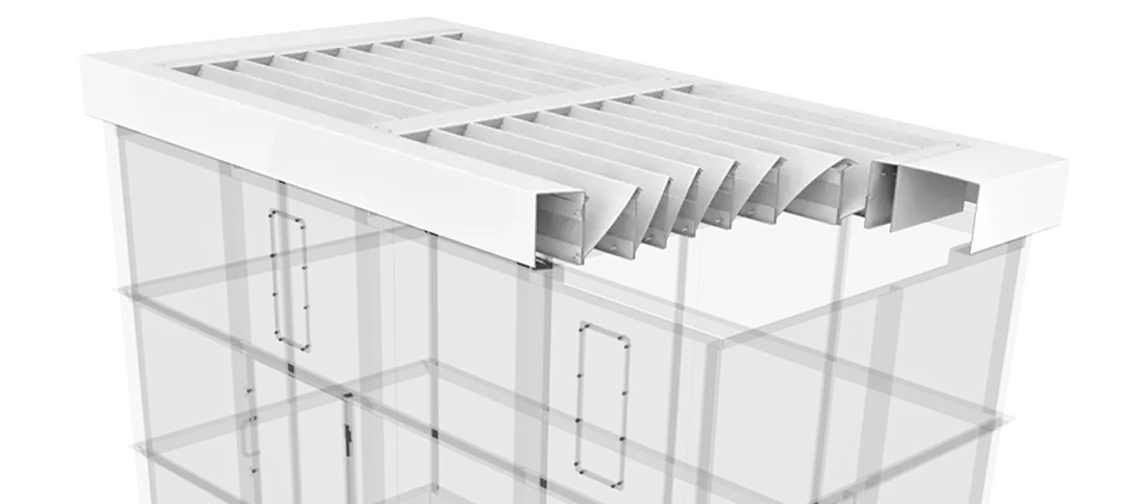

Among other things, this device can be integrated into almost any equipment used in the technological line, as well as in containers for transportation of bulk goods (container for transportation of grain cargoes), in weighing equipment, etc., more details.

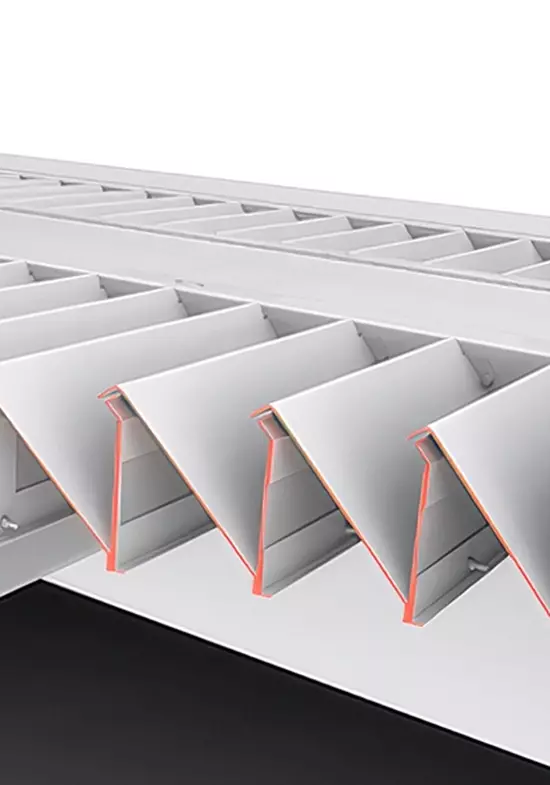

The main distinguishing features of the Flap-system developed by us:

- Reduction of probability of occurrence of uncontrolled injection flows of grain dust and their further spreading into the environment.

- Reducing the sharp load on the walls of the tank, bunker, container, etc., which is present in the conventional scheme of bulk product feeding.

- Reducing the spread of dust and limiting its release into the environment. The device leaves a significant part of the dust in the hopper container, backfill pit, etc.

- Reducing the risks of foreign objects larger than 150x150x150 mm getting into the product.

From all of the above it follows that the feeding of bulk product can take place without the involvement of additional equipment for dust removal and significantly reduce the number of operating personnel and energy costs for aspiration plants, which will certainly bring a significant economic benefit to the operating company as a whole.