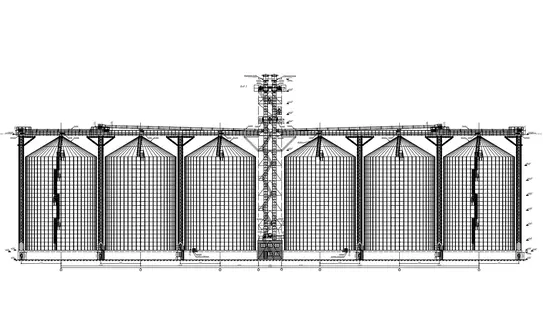

Symaga grain storage silos

Silo design

Symaga grain storage silos are designed for long-term and temporary storage of grain in both temperate climates and in conditions with high humidity levels, as well as high wind and snow loads.

Symaga silo types:

- Silos on concrete foundation (flat bottom): designed for long-term grain storage.

- Hopper silos (with metal hopper): used for permanent and temporary operational storage of all types of grain crops.

- Loading silos (bunkers): are silos with the volume from 27 m³ to 267 m³, specially designed for loading grain trucks or railway cars.

- Farm silos: small volume hopper silos, which are actively used in mini grain elevators.

Characteristics and advantages of Symaga silos

Silo roof:

It is made at an angle of 30º and consists of trapezoidal sections galvanized with 250 g of zinc per m², which ensures a reliable, airtight and watertight structure. The steel grade S 280 GD complies with UNE-EN-10346 (2009), has a yield strength of 280 N/mm² and a tensile strength of 360 N/mm².

Silo body:

The cylinder is made of sheets of corrugated structural steel grade S 350GDZ600, which is galvanized by the Sendzimir method at a rate of 600 g of zinc per 1 m². The thickness of the steel is determined depending on the sheet and ranges from 0.8 to 4 mm. The yield strength is 350 N/mm² and the tensile strength is 420 N/mm². Each silo is equipped with wind rings to ensure structural stability in high winds.

Bolted connection:

All parts of the silo are fastened with galvanized bolts (70-85 μm) manufactured according to DIN 933, strength classes 8.8 and 10.9. The bolts are tightened with galvanized nuts of strength class 8 according to DIN 934.

Sealing:

For sealing vertical sheet metal joints and funnel joints, 6 mm diameter gaskets made of a butyl rubber compound are used. Neoprene gasket washers are used to seal bolted joints.

Overhead silo galleries:

The gallery consists of two sections (for service and for the conveyor) with a width of 70 cm and with double auxiliary railings with a height of 110 cm. Its structure is made of galvanized steel beams (275 g/m²), "U"-shaped, 263 mm wide. The steel complies with UNE-EN-10346: 2009, with a yield strength of 280 N/mm² and a tensile strength of 360 N/mm² (grade S 280 GD).

Silo maintenance:

The silo is designed with ladders, inspection hatches and maintenance hatches.

Options

Silo ventilation and aeration system:

The aeration system uses H-shaped system made of special galvanized corrugated steel sheet. The ventilation system provides for the installation of centrifugal fans, the ducts of which are equipped with protective grilles against birds.

Grain temperature control system:

Silo thermometry includes the possibility to visualize the processes of temperature change of the stored product, equipped with PC, sensors and RS232 communication interface. The sensor system complies with the fire and intrinsic safety requirements for the ATEX 20 zone.