A modern elevator is impossible without automated control systems

Grain Capital Automation Department Philosophy: Systematic Approach to Control System Design

The philosophy of Grain Capital's Automation Department is based on a systematic approach to control system design and an in-depth study of process automation facilities. The activities of the department are the result of a natural symbiosis of experience and knowledge of specialists from different departments, such as technologists, designers of transportation and aspiration departments. This is the reason why Grain Capital's automated control systems fully meet the requirements of modern elevator complexes and ensure their efficient operation.

What are the challenges of elevator automation?

Automated control systems help to minimize errors associated with the influence of human factor on the production process, reduce grain losses during transportation, increase the life of equipment by optimizing its operation and improve the energy efficiency of the elevator complex.

What services does Grain Capital's automation department offer to its clients?

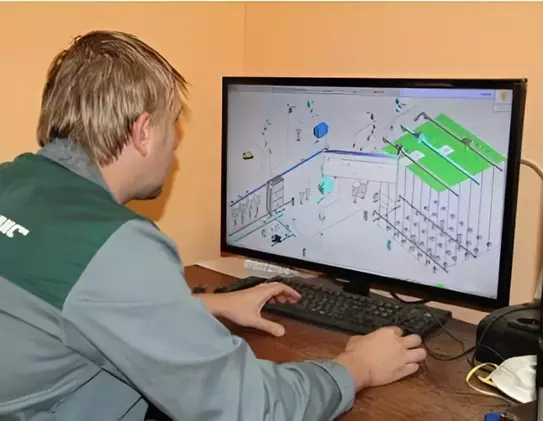

Our department offers our clients software and hardware complexes "GC-System", which represent various systems of remote automated control. The ideology, which we adhere to in our developments, corresponds to the modern world trends of automation - standardization, universality, continuity of versions.

The control systems created by our creative team have the possibility of evolutionary development. The basis of software and hardware complexes "GC-System" are standard modules developed by us for both technical and software. Depending on the functionality and scale of the project, we assemble it from these standard modules, which allows us to meet the customer's needs as much as possible.

In addition, if in the future there is a need to expand production, change the product transportation scheme or add new process units, there will be no need for a complete redesign of the system. The existing control system can be supplemented with the necessary modules to achieve a new level of production quality without significant material costs.

Software solutions for different types of grain elevators

- "Farmer GC" - suitable for small grain storage facilities of farms, which include an auto-acceptance and unloading unit, several bins and a grain dryer.

- "Warehouse GC" - designed for large farms that have several floor storage warehouses, grain cleaning and drying units, auto receiving and unloading units.

- "Elevator GC" - a convenient tool for managing linear elevators of various capacities with a large number of silos, transport equipment, gravity equipment and dedusting systems.

- "Feed GC" - designed for feed mills, includes weight batching and metering functions.

- "Port GC" - suitable for managing port terminals with large storage capacities, high throughput and a wide range of grain.

Functionality and benefits

Grain Capital's GC-System remote automation systems are characterized by high functionality and innovative approaches. For example, the "Point & Start" function independently selects the optimal grain transportation route, taking into account the current state of the equipment, and the "OptiFill" function controls the speed of product reception, ensuring maximum productivity of the system.

Energy efficiency and resource saving

One of the main advantages of our systems is energy savings. With the growing demand for energy and challenges in energy supply, energy efficiency is becoming an important priority for today's businesses. Our experts have developed an energy efficiency program that includes optimal location of distribution points, use of innovative equipment that reduces peak loads, and implementation of algorithmic software that can reduce electricity consumption by up to 11%.

The most important advantage is our people

However, Grain Capital's greatest asset is our people - the people who build this product. Thanks to their dedication, we are able to offer our customers the best automation solutions.

Controlling the temperature of the grain in the silo

Grain temperature control is a critical aspect of grain elevator operation. For effective fulfillment of this task we offer software and hardware complex "Oberir GC". This temperature control system timely identifies centers of grain self-heating, which allows taking preventive measures and "recovery" of grain.

The Ukrainian market is saturated with various systems of grain temperature control, which are built on a similar element base. The main differences are the level of reliability of their operation and software functionality.

Our complex "Oberig GC" allows to analyze the state of stored grain according to several algorithms and offers different types of visualization for timely implementation of measures aimed at minimizing losses. Oberig GC is truly the protection that helps you save your crops.