Maintaining grain quality is task No. 1 for a modern elevator

Preserving grain quality is a top priority for a modern grain elevator

Grain is one of the most important products in the world, and Ukraine remains one of its leading exporters. Despite the military actions that have affected infrastructure and logistics, interest in Ukraine as a strategic partner in grain exports not only remains but is growing. This requires increased attention to the preservation of grain quality.

At the beginning of the 20th century, yields were only 5-7 c/ha, and the total grain harvest in Ukraine was about 10-15 million tons. However, by 2012, yields had increased to 32-37 c/ha, which led to an increase in gross harvest to 60 million tons. As of 2024, despite all challenges, the average yield of grain crops in Ukraine has reached 45-50 c/ha and the gross harvest is about 80 million tons.

These significant changes have increased the requirements for the quality of grain stored and transported. Careful transportation and proper storage ensure maximum quality of grain products, which is critical for the food industry, especially with the growing demands of international markets.

Losses of marketable grain: analysis of the situation

Every year a significant amount of marketable grain goes to waste due to damage during technological operations. In particular, the analysis of Ukrainian enterprises shows that the increase in grain breakage is:

- 4.0-6.5% for procurement enterprises using mobile mechanization and bucket loaders;

- 2.0-4.0% for transshipment elevators with full stationary mechanization.

Table 1 shows the coefficients of broken grain caused by transport and gravity-transport equipment, which shows that the total broken grain coefficient is 2.2%, which exceeds the acceptable level of 1.5%.

Average increase in grain yield - Transshipment elevator

| Name of the site | Absolute value | % in the total increase in combat at the enterprise | |

|---|---|---|---|

| from | to | ||

| Gravity transport | 0,6 | 0,6 | 15 |

| Acceptance from motor vehicles | 0,06 | 0,12 | 3 |

| Loading into railroad cars | 0,12 | 0,24 | 6 |

| Points of overload | 0,10 | 0,20 | 5 |

| Chain conveyors | 0,44 | 0,88 | 17 |

| Norias | 0,2 | 0,4 | 10 |

| Tanks (warehouses, silos) | 0,78 | 1,56 | 39 |

| Total: | 2,0 | 4,0 | 100 |

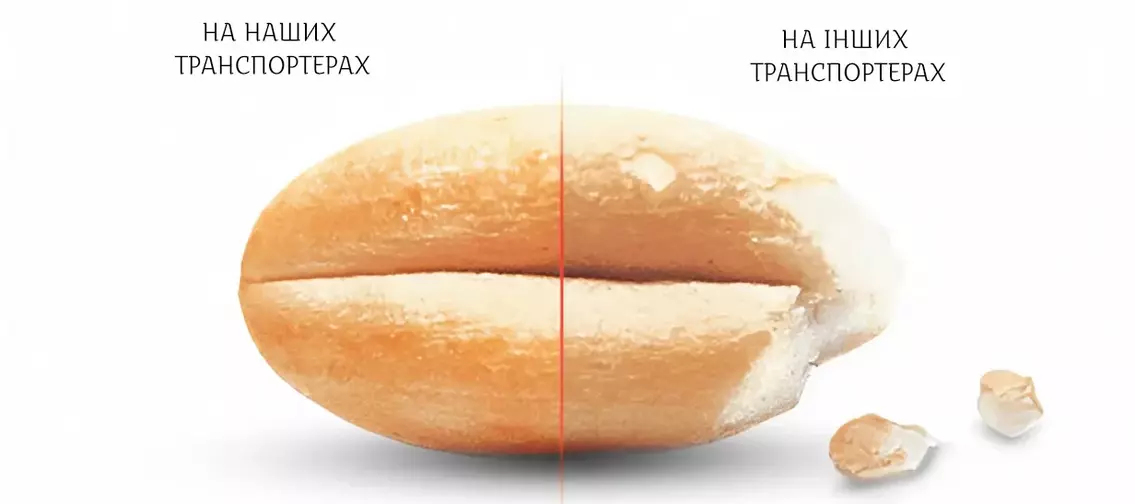

For a transshipment complex with an annual turnover of 1.1 million tons, this means that the enterprise loses 3.3 thousand tons of grain of marketable quality annually, which at an average cost of grain of 2000 UAH/ton is a loss of 6.6 million UAH. The solution of this problem requires not only negotiations with customers, but also search for new technological solutions to preserve the quality of grain.

Research and Development: Reducing Grain Fracture Coefficient

Grain Capital Design Bureau together with the departments of Odessa National Technological University have conducted research into the causes of grain breakage in transportation and gravity-transport equipment, and developed methods of its reduction.

Reasons for the increase of the fight coefficient in elevators:

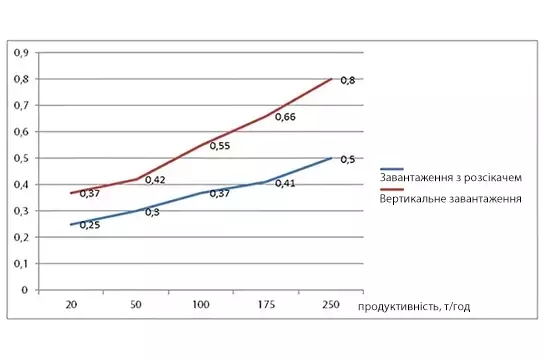

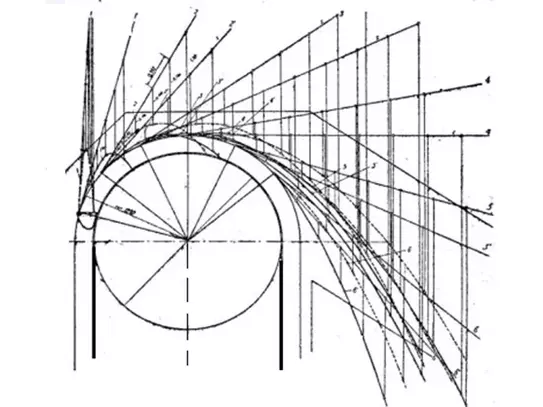

- Filling of elevator buckets: Grain in buckets receives shock impulses due to the difference of kinetic energy vector of grain and elevator buckets during their collision. Shock forces can be reduced by synchronizing the bucket trajectory with the grain feed trajectory, which has been implemented in the elevator feeders developed by Grain Capital.

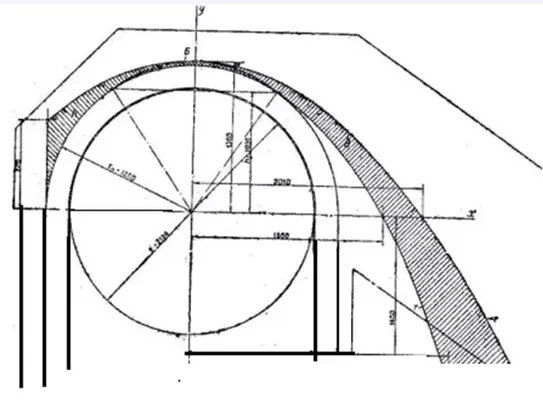

- Bucket and outlet geometry: It is important that the outlet guide the grain into the outlet, minimizing contact with the elevator head housing. Grain Capital elevators provide a smooth, gliding grain flow direction that significantly reduces the breakage rate.

- Grain backfeed: The Grain Capital elevators are completely free of grain backfeed thanks to the splash guard in the head.

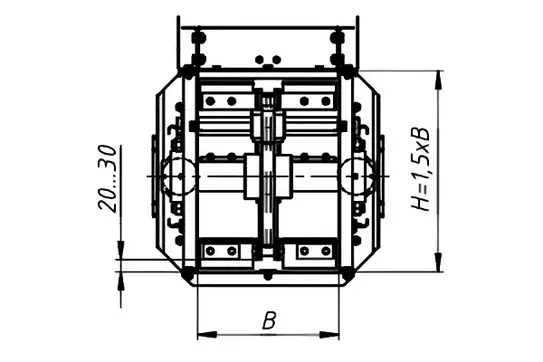

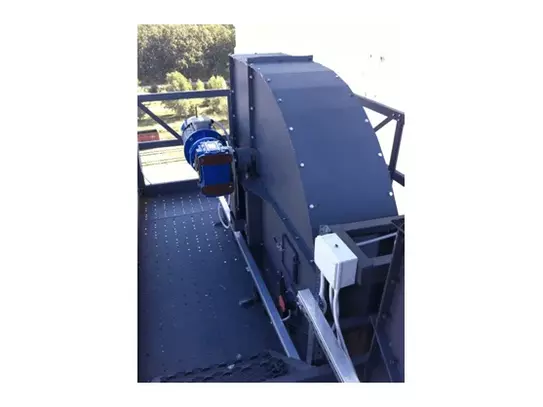

Scraper conveyors:

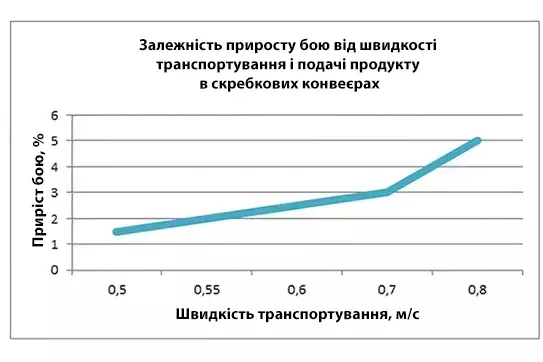

Scraper conveyors have a number of advantages, but they can also be a source of high incremental grain breakage due to the contact of the traction arm with the hulls, high conveying speeds, and the use of steel scrapers.

Grain Capital conveyors eliminate these disadvantages due to low-speed modes (up to 0.5 m/s), absence of direct contact between the chain and the body and use of scrapers made of special elastomeric material, which eliminates grain breakage.

Thanks to these measures, it has been possible to reduce the ratio of increase in fight by 1.5-2 times compared to the existing analogs on the market.

Grain Capital's research and equipment improvements allow us to provide farmers with solutions that not only meet modern quality standards, but also minimize the negative impact of technological processes on grain quality. Preserving grain quality is a priority for modern grain elevators, and Grain Capital helps meet this challenge by providing innovative solutions for the grain processing industry.

The author of the article: O.I. Gaponyuk, Dr. of Engineering Sciences, Professor of Odessa National Technological University.