Efficiency of the selected equipment

Each of us thinks we know what an efficient elevator is and how to maximize profit from its operation. This certainly contributes to self-motivation in optimizing and developing the business, but do we observe all the necessary conditions in doing so?

If we analyze the costing of a full-cycle elevator, whether it is a grain terminal or a grain elevator, we can immediately draw attention to the three main components that form the costs:

- Wages of personnel operating the elevator.

- Energy and resource intensity of the machinery.

- Service maintenance, which keeps the elevator in proper condition.

All three indicators depend not only on the efficiency of the adopted design solutions, but also on the efficiency of the purchased technological equipment and the qualification of the personnel working with it.

What is equipment efficiency

Equipment efficiency is a complex criterion that includes:

- Cost of operation (consumables, service, maintaining product quality).

- Energy consumption during movement.

- No downtime due to sudden breakdowns (emergency repairs).

- Minimal need for personnel intervention in the operation process.

Main criteria of equipment efficiency:

- The duration of equipment operation before the first overhaul must exceed the payback period of the elevator. Otherwise, the payback period will exceed the planned figures.

- The energy consumption of the equipment must be minimized.

- Reliability of the equipment: the supplier must take into account all peculiarities and operating conditions.

- Service by in-house personnel should be minimized and maintenance costs should not exceed nameplate data.

If the equipment is durable and reliable, scheduled repairs should be performed less frequently, thus optimizing the number of personnel. Grain Capital offered the market an innovative SMART-Individual product for the formation of preventive maintenance tasks. What is the peculiarity of this solution?

SMART-Individual product features

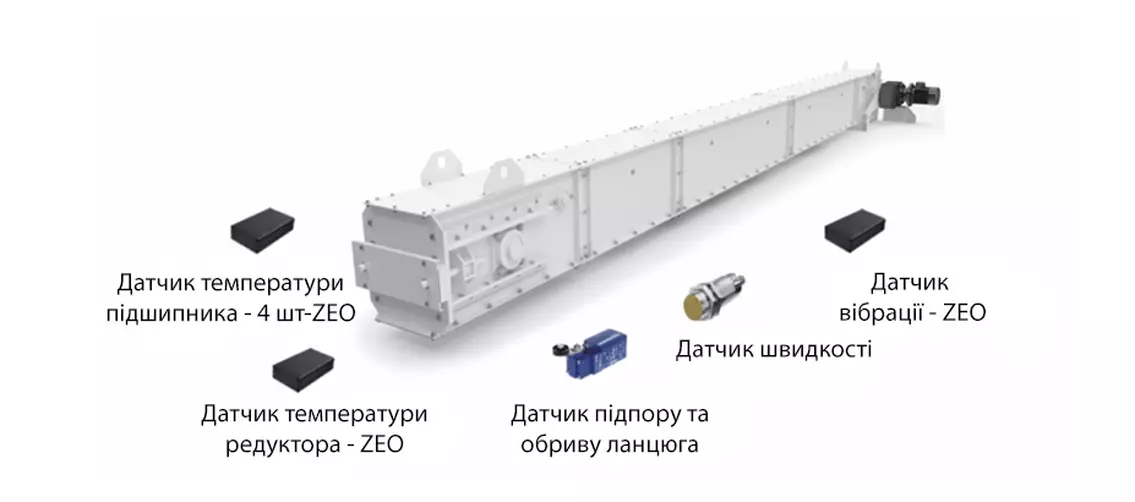

This product has been developed in response to numerous requests from our customers. We analyzed the market and came to the conclusion that technologies similar to those used in the machine tool and automotive industries should also be introduced in the field of grain storage and processing. SMART-Individual is a system of self-diagnostics and analysis of the technical condition of equipment, which allows to almost completely eliminate the human factor from the diagnostic process, as well as to prevent emergency situations. This reduces the need for a large maintenance staff. Using Grain Capital's professional service is much less expensive than maintaining your own staff.

SMART technology also allows for comprehensive automation of the facility at the highest level. What sets our SMART system apart from existing basic control systems is its simplicity, versatility and innovative approach to automation. You don't need expensive controllers and kilometers of cables to control your elevator. We have prepared a comparison table to demonstrate the advantages.

| Consequence | Classic SCADA | SMART-Individual |

|---|---|---|

| 1. Failure of the central controller | Leads to a complete elevator shutdown | Stops only a single unit of equipment |

| 2. Development of complex software | Requires complex software | Software is provided with the equipment |

| 3. Load on the central controller | Increases with more equipment | Slightly increases, requirements are reduced |

| 4. Need to purchase automation modules | Modules must be purchased separately | Automation is provided with the equipment |

| 5. Number of cables | Requires a large number of cables | Minimal number of cables due to local controllers |

| 6. Automation design | Significant amount of work | Reduced amount of work |

| 7. Installation work | Higher volume of work | Reduced volume of work |

| 8. Equipment setup | Significant amount of work | Minimal work, performed at the factory |

| 9. Safety operation parameters | Monitored minimally | Additional parameters monitored, such as temperature, vibration, voltage, integration with video surveillance |

| 10. Fault diagnostics | Available only from the central post | Also available via Wi-Fi |

| 11. Documentation | Paper-based, unsystematic | Electronic, embedded in the controller |

| 12. Maintenance schedule | Requires development, controlled by old methods | Preset at the factory, controlled electronically |

| 13. Equipment management | By individual units | As a complex unit |

| 14. WEB interface | Requires license, common for the entire elevator | User-friendly WEB interface for each unit of equipment |

Operating costs and equipment selection

The use of SMART-Individual allows you to reduce operating costs. According to data from a number of enterprises, the average cost of maintaining a unit of process equipment is from $500 to $1000 per year, of which 55-60% is the salary of personnel for repair work. If the enterprise has more than 50 units of equipment, maintenance costs can be from $50 thousand and more per year.

The main stage affecting efficiency is the formation of the technical specification (TS) for the purchase of equipment. The first criterion of the TOR is the type, design and manufacturer of the actuator. Even the best quality actuator will not be durable if it is not selected correctly. The service factor is an important factor: for a grain elevator it should be at least 1.3, for a port terminal - at least 2, and sometimes 2.5-3.

Recommendations for equipment selection

- Be sure to request a traction calculation for each piece of equipment and basic figures for design loads.

- Check the capacity margin of the equipment, especially when handling different crops with different characteristics.

- Involve specialist consultants to advise you and check the supplier's calculations.

Conclusion

The question of selecting equipment is a very responsible stage, at which there are many chances for error. The main criterion should be the openness and professionalism of the manufacturer. This can only be assessed in a close discussion when discussing the commercial offer and technical issues with the supplier.

Thus, the right approach to equipment selection will avoid many problems in the future and ensure efficient operation of the elevator, which will increase its profitability and competitiveness.