Preparing for the new season

How to properly prepare the elevator for the new harvest?

Two main types of grain storage are common in Ukraine: vertical (reinforced concrete or metal silos) and horizontal (floor storage warehouses, silos, currents). Recently, metal silos have been widely used, which can reach a diameter of up to 35 meters and hold up to 25 thousand m³. Undoubtedly, when storing such a volume of grain, special attention should be paid to its safety.

Nowadays, there is a lot of discussion about the feasibility and complexity of grain storage in metal silos. Problems of moisture condensation, caking, difficult air exchange of grain and drop height are the factors that negatively affect the process of grain storage in metal silos. However, if you look at grain storage in reinforced concrete silos, you will notice almost the same negative factors. The only exception is moisture condensation. Due to the low thermal conductivity of concrete and the temperature gradient, this factor is practically absent, which improves the quality of the stored grain.

Horizontal grain storage also has its disadvantages, but these affect the economics more than the quality of storage. Floor storage warehouses are better suited for storing oilseeds and corn.

It is impossible to state categorically which type of storage is the best, but practice shows that silos are best for grain crops and floor storage warehouses are best for oilseeds. Both of these methods are successfully used in Ukraine. However, in order for grain to be stored properly and not to lose its quality, it is necessary to prepare grain storage facilities (elevators) thoroughly and in time for storage of crops in the new season.

What to pay attention to when cleaning grain from a grain storage facility?

When unloading grain from vertical storage silos, several important points should be taken into account. In the case of metal silos with several discharge openings, unloading should be started exclusively through the central hopper until the grain is completely unloaded in the center of the silo. Only then can the side flaps be opened. It should also be remembered that during loading of the silo a self-sorting process takes place and most of the impurities accumulate on the silo walls. Consequently, higher levels of impurities may be observed when discharging the residual grain, especially if there are several full discharges without cleaning the silo.

Preparation time for the elevator

Preparations should be started well in advance of the start of harvesting and receiving.

At each elevator, the so-called "technical base" must be prepared. This means that the enterprises, as far as possible, should free the storage facilities from grain, carry out fumigation, revision and repair of transportation elements, and, if necessary, reconstruction or technical re-equipment of storage facilities. This depends on what budget funds have been planned and allocated by the elevator management for reconstruction.

During technological processes at the enterprise it is important to monitor the technical condition of transportation and technological flows to identify the main problem areas. The plan of repair works for the next year should be drawn up during the whole period of grain acceptance to the elevator in the current year.

Since gravity and transportation equipment is subject to the most intensive wear and tear, special attention should be paid to these types of equipment. The technical service of the enterprise is obliged to prepare not only defect certificates for repair or replacement of equipment units, but also preventive maintenance plans to prevent unforeseen stoppages due to breakdowns.

Taking into account the seasonal nature of the enterprises' work, special attention should be paid to timely preparatory and repair works during the winter downtime of the enterprise. The management of the enterprise should make a plan, approve the budget for planned repair works and ensure their financing depending on the tentative business plan for the next year. For proper budgeting of repair work it is necessary to study in detail the log of maintenance of the main equipment and conduct a detailed analysis of the condition of the units that require maintenance and repair. Such a scheme of work will ensure successful operation of transportation and technological lines during grain harvesting.

One of the problems that enterprises face during preparation is the workload of elevator equipment manufacturers. Therefore, farms and elevators, which delay in determining the equipment required for replacement and ordering it in time, find themselves in a difficult situation due to long lead time and overpriced equipment. In addition, during the preparation period there is a risk of purchasing low-quality equipment from companies engaged in the resale of products manufactured under improper conditions without observing all the necessary steps in production.

Therefore, the optimal time to purchase equipment is the winter period (starting from November), as production companies have free production capacity and are interested in concluding contracts at more favorable prices for the customer.

What should you pay attention to when carrying out repair work?

The following factors should be considered during the renovation:

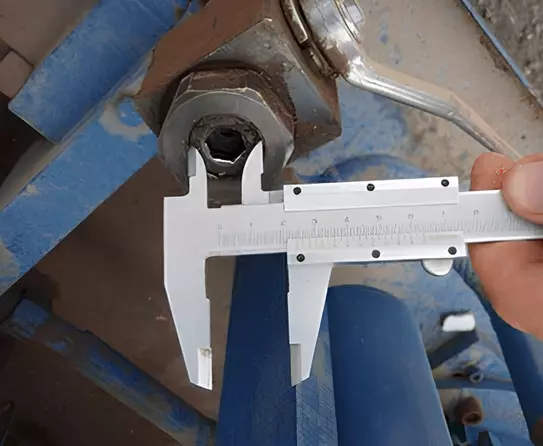

- Equipment condition. It is important to check the condition of bearings for backlash, availability of lubricants, integrity of the housing, inspection of the bearing seat, its temperature (using thermal imager) and quality of rotation, condition of hinge elements, traction elements (for visible defects and damage). Also all elevator buckets should be inspected and scraper (chain) conveyors should be checked.

- Checking the quality of the technological process. The level and degree of technical re-equipment and repair is determined by the technical service of the enterprise. If the quality is not up to standard, this can lead to malfunctions.

Signs of malfunctions of systems of elevator units. The main signs are decrease in productivity, emergency stops, increase in damaged grain particles, increase in noise and vibration characteristics of the equipment.

Unstable operation of the plant indicates a malfunction of some system or mechanism. It can be either an automatic control system or a bearing in the conveyor. All this negatively affects the operation of the enterprise.

In order to make the right decision: whether to carry out the work yourself or to engage a contracting organization, it is necessary to monitor the transport and technological systems of the enterprise. Only after a complete assessment of the technical condition can conclusions be drawn about the feasibility of repair by own efforts or by engaging specialists.

It is better to entrust the preparation of the enterprise to professionals, but with obligatory control of work performance. A clear plan and schedule of work is a guarantee of successful preparation of the enterprise for the new harvest.

Author of the article: Igor Gaponyuk, Director of Development at Grain Capital.