A new look at old equipment (automation)

System of automatic control of the unloading cart

Basic prerequisites

Recent years demonstrate the rapid development of grain crop production as a priority sector of Ukraine's agricultural industry. Domestic grain remains a competitive commodity in both domestic and foreign markets, which makes this sector particularly attractive for investment and development.

Grain Capital focuses on creating modern and highly efficient equipment for grain processing plants. The projects developed by Grain Capital specialists help to reduce the cost of construction of new facilities, shorten the time of their construction, reduce energy intensity, and allow for future expansion of complexes with minimal capital investments. All this increases the competitiveness of products and contributes to the growth of business profitability.

Grain Capital's automation department's new development, the Automatic Unloading Cart Control System, deserves special attention. This innovative solution gives standard equipment new functionality never before available on the market.

Description of the unloading cart

Unloading cart is a device installed on over-silo belt conveyors and performing the function of automated grain unloading.

The need to introduce this system is due to the fact that the elevator equipment, in particular the equipment of the elevated floor, has not been significantly modernized or reconstructed for a long time. Most of the equipment used on the elevated floors has been in operation for more than 20-30 years, which significantly reduces the efficiency of production processes (see Fig. 1. Elevated Floor Conveyor).

What is a standard unloading device? It is an electrically driven self-propelled cart moving on rails mounted above the belt conveyor. To unload the product from the belt with the help of guide drums, the cart is equipped with an envelope loop, which discharges the grain into the receiving chute. The shifting valve located in the receiving chute distributes the grain flow to the left or right gravity feeders, which direct the grain to the silo receiving hatches.

For electric power supply of the main drive motors and the flap valve drive, a multi-core flexible cable in rubber insulation is connected to the unloading cart, which is pulled behind the cart in a special box or suspended on a trailing line along the entire length of the silo.

In order to realize precise positioning of the cart over the receiving hatches, limit switches were installed on the conveyor frame in the places where the cart stopped (Fig. 2. Modified unloading cart equipped with automation and aspiration system).

The main disadvantages of the "old" unloading cart control system are:

- Short life of expensive multi-core flexible cable in rubber insulation.

- Large number of contact elements (track limit switches) that require constant maintenance as they operate in dusty environments.

- Large number of cables for connection of track limit switches and discrete level sensors in silos.

- Limited functions of the device.

- If the cart is equipped with an additional device, an additional trailing cable is required.

- Labor-intensive service.

A new spirit in an old body: innovations in unloader control

The automatic unloading cart control system developed by Grain Capital's automation department is a complete intelligent device that combines state-of-the-art software and hardware solutions for efficient control of elevator equipment. It eliminates a number of existing problems and significantly increases the functionality of standard equipment.

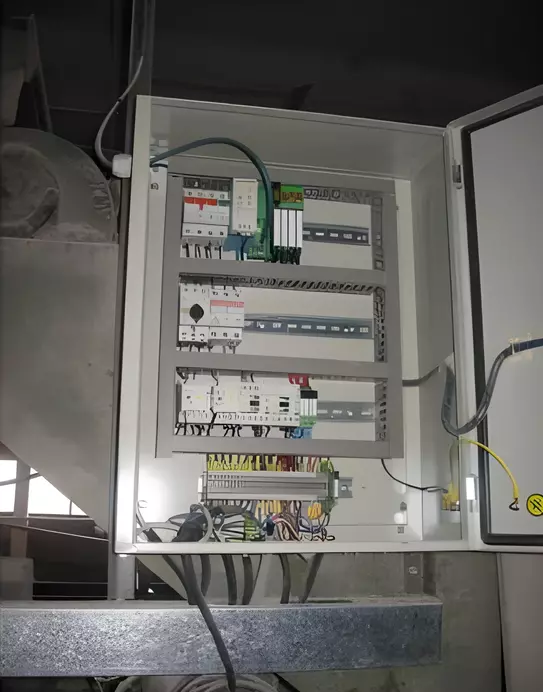

The system is based on the ILC 130 ETH programmable controller, which provides control and management of all cart functions, including movement, positioning and distribution of product flow. The cart now requires only one standard four-wire cable with a small cross-section, which significantly reduces wiring costs (see Fig. 5. Unloading cart control panel).

Control features

The cart units can be controlled locally (set-up) via a push-button control station or automatically by integrating the controller into a remote automated elevator control system. Thanks to the standard Profinet communication protocol, this process requires little effort (see Fig. 5. Bluetooth adapter and ILC 130 ETH controller).

Control signals and status information for all sensors and devices on the cart are transmitted via radio using the Factoryline Wireless Bluetooth V2.0 FL BT EPA Bluetooth adapter. This eliminates any restrictions on the amount of information that can be transmitted from the unloading cart.

The positioning of the cart is now accomplished with just one proximity sensor mounted on the cart and a non-volatile control system. This ensures that information on the status of all units is retained even in the event of a power failure.

Innovations in data transmission and monitoring

Wireless data transmission significantly reduces cabling costs and allows the position of the cart to be continuously monitored with an accuracy of up to 5 mm (see Fig. 5. Positioning sensor).

Analog level sensors on the tippers (radar or mechanical), which provide information about the level of grain in the silo, can be installed in addition to the standard equipment of the cart. This data is also transmitted wirelessly.

Innovative approach to dedusting

Another innovation from Grain Capital is the development of a system for dedusting the elevator floor above the silo. Eliminating the energy-intensive and difficult to maintain slot aspiration system in favor of a local self-cleaning filter mounted directly on the cart discharge chute is a significant step forward in improving environmental safety.

The filter operation is controlled through the control system of the unloading cart, taking into account the condition of filtering elements and selection of filtration mode depending on the type of grain (see Fig. 5. installation of the local filter).

Safety Assurance

The unloading cart is equipped with sound and light alarms that are fully compliant with industry safety requirements.

The entire control system is based on the equipment of Phoenix Contact (Germany), a leader in innovative technologies of industrial connections, automation and protection of electronic devices from overvoltage. Phoenix Contact equipment is certified in Ukraine, known for its high quality, reliability, and ability to operate in a wide range of temperatures and high vibration.

Testing and implementation

The system of automatic unloading cart control has passed industrial tests and was successfully implemented at Rakhnyansky elevator, which belongs to Louis Dreyfus Commodities L.T.D. Ukraine Ltd. The system functions without failures and demonstrates high efficiency.

The development and implementation of this system is not just the creation of a new device, but a new way of looking at elevator equipment, improving the quality of standard mechanisms and reducing the cost of their operation and maintenance.

Author of the article: Grain Capita Development Director - Igor Gaponyuk.