Press release of Terra LLC

Design, manufacture, installation and customization of electric power and remote automated control systems for grain processing industry enterprises, elevators and grain terminals.

Task description

Terra LLC is a leading manufacturer of cereals and flakes in Ukraine. Due to the growth of production, the Board of Directors decided to increase production capacity for storage of raw materials. It was necessary to provide a modern technical solution to realize this task in a short period of time with minimal investment and without loss of quality, which would allow us to be ahead of competitors in the market.

The technical solution had to fully comply with the best European examples of MES systems, providing efficient process control with low operating costs.

Solution Description

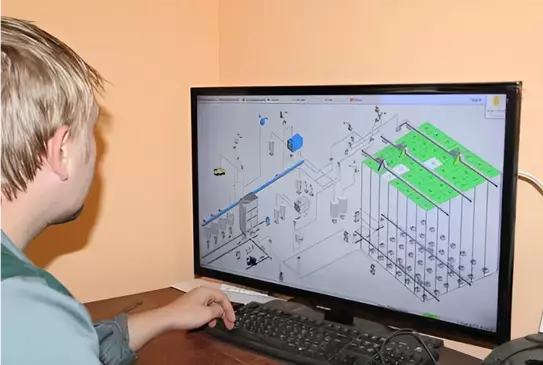

A grain elevator is a complex process system that includes a significant number of transport mechanisms, gravity flow mechanisms, grain level sensors, equipment safety sensors and positioning mechanisms. They are usually located at considerable distances from each other and from a central distribution point, often in unheated rooms or outdoors.

The traditional solution involves running control cables to the sensors and power cables to the actuators from the power and automation control cabinets. In a grain elevator with a capacity of about 30,000 tons of grain, the total length of these cables can reach 10-20 kilometers.

For several years, specialists of Grain Capital's automation department have been using distributed peripheral technology in their developments. Work on the project of electric power and remote automated control system of Terra LLC elevator in Pervomayskiy town of Kharkiv region was not an exception.

Local control cabinets with Axioline I/O devices and Conactron hybrid reversing starters, which have an extended operating temperature range, were built to collect information from ninety-four silo level sensors, control more than eighty diverter valves and gate valves, and position the three loading carts above the silo.

This eliminated the need to run kilometers of cables throughout the entire elevator. Only two cables had to be laid to the distributed periphery cabinets on all floors of the elevator from the central distribution point: a VVGng power cable with a cross-section of only 2.5 mm² from the common switch and an interface cable to the CPU. It is worth noting that Axioline I/O devices are fully compatible with devices from other manufacturers, as the Siemens S7-317 PN/DP controller was used as the central processor in this project.

Solution advantages

The compactness of the ELR H5-I-SC-230AC/500AC-2 hybrid starters reduced the number of electrical power control cabinets by 30%.

Reduced cabling costs: by using distributed I/O technology and Axioline devices for this project, cabling costs were reduced by 17% and installation time was reduced by 20%.

Professional support of Phoenix Contact products.

A wide network of Phoenix Contact representative offices and partners in Ukraine.

Read more about the work of the automation department here.

Author of the article:

A.I. Gaponyuk, Dr. Sci. in Engineering, Professor, Odessa National Technological University, Odessa.