Experience in designing port grain terminals

Design experience of port grain terminals. Main aspects in construction and operation.

Main marine terminals

Ukraine has the most powerful port potential among all the countries of the Black Sea region. There are 13 commercial seaports (Reniysk, Izmail, Ust-Dunai, Belgorod-Dnestrovsky, Ilyichevsky, Odessa, Yuzhny, Mykolaiv, Oktyabrsky, Kherson, Skadovsky, Berdyansky, Mariupol) and 12 port points on the Black Sea and Azov Sea coasts.

Competitive environment

The total transshipment capacity of grain terminals in Ukraine is still sufficient for the planned exports. According to our estimates, it is about 55 million tons, with exports of 30 million tons. Taking into account the growth rate of the gross grain harvest in Ukraine, in the coming years the harvest may reach 80 million tons per year, and exports - up to 60 million tons. As for transshipment capacities, we believe they will grow to 65-70 million tons. Full saturation of transshipment terminals will take 2-3 years.

Already today, existing grain terminals are upgrading their elevator facilities to increase the capacity of receiving, transporting and loading grain onto ships. Our company's forecasts have come true, and we are already seeing competition between terminals. Those who can accept more grain from railroads and trucks and load more ships in a short time are in the best position. Obviously, the main grain cargo flow will be directed to deep-water terminals, where rail and road logistics will work efficiently.

"Bottlenecks of port terminals

If exports through Ukrainian seaports grow, the main problem will arise not in grain storage capacity at ports, but in access roads. The main problem is narrow and congested roads at the entrances to the ports, creating a bottle-neck effect. It is necessary to localize these bottlenecks and increase their capacity.

It is required to expand highways in the port area with the creation of parking lots and increase the number of railroad branches to port grain terminals. The solution to this problem depends on the domestic economic situation in the country. As noted earlier, Ukrainian ports suffer due to insufficient capacity of the railroad network.

Not all sections on the approaches to sea harbors are electrified, so freight trains have to switch from electric traction to thermal traction. In addition, on some routes, additional tracks need to be built, as the existing ones cannot handle the required number of freight trains. The capacity of port stations is also limited, which does not always allow handling the required number of railcars in a timely manner.

It is not yet known how much Ukraine will spend for these purposes, but Ukrzaliznytsia has already identified the sections that need modernization. We are talking about electrification and construction of additional tracks on the Volnovakha-Kamysh-Zarya-Zaporizhzhya routes, as well as Dolinskaya-Nikolaev-Kherson-Dzhankoy, Chornomorskaya-Beregovaya, and Kolosovka-Nikolaev.

Some private port operators have also announced plans to develop port railroads. For example, electrification of one kilometer of track costs UAH 2.1 million. The main question is who will pay for it: the state or a private investor? Most ports in Ukraine are located in areas of mass urban development, and it is possible to expand road infrastructure only through demolition of buildings and resettlement of people, which requires significant investment and a nationwide program.

There is also a problem of finding new sites for the construction of marine grain handling complexes, in particular due to the shortage of relevant land plots in the Black Sea zone.

Problems with railroad capacity do not reduce the difficulties of taking new railroad branches to the planned terminals. For example, the port of Ochakov is not being developed because of the need to build 65 km of railroad track from the nearest station, which deters investors.

Grain Capital Group of Companies

One of the key activities of Grain Capital Group of Companies is turnkey design and construction of both grain elevators and grain handling marine terminals. A group of professionals (technologists, logisticians, economists, builders) starts working with a potential investor at the stage of selecting the most promising site. Infrastructure and the competitive environment are studied and analyzed, and pre-project decisions at the feasibility study stage calculate the amount of investment required and the expected payback period.

Brooklyn-Kiev marine grain handling terminal

A vivid example of a successful project is the terminal of Brooklyn-Kiev LLC, built by the company in the port of Odessa. The projected transshipment capacity of the terminal is 4.5 million tons per year, with the possibility of simultaneous storage of 240 thousand tons of grain. The first stage has already been commissioned, which allows for the transshipment of 0.5 million tons of cargo per year.

The location for the construction of the grain terminal was chosen taking into account numerous economic and logistical criteria. As a result, this site has a number of advantages over other potentially interesting locations, which, incidentally, are few in number. The site was selected taking into account the following factors:

Firstly, Odessa has historically, for more than two hundred years, been the grain gateway of the country.

Secondly, the location of the terminal site of Brooklyn-Kiev LLC allows using a unique new transport overpass leading from the city directly to the center of the port. Grain trucks do not interfere with city traffic and do not create congestion on the roads, which often happens in other port cities. The high throughput capacity of railway transportation is also of no small importance.

Thirdly, a significant advantage is the closed water area of the port, which allows receiving and dispatching ships during 10-11 months of the year. The shape of the harbor does not allow winds to blow through its territory and berths, and also creates conditions for non-freezing of water.

Fourthly, the bottom depth at the loading berth is now 12 meters, which allows to receive vessels with displacement up to 60 thousand tons. However, taking into account the dredging works, in the nearest future the depth will reach 13.5-14 meters, which will allow to receive vessels with displacement up to 90 thousand tons.

The best world technologies of grain reception, transportation and storage were applied and implemented during the design of the terminal. Today it is the most progressive grain terminal on the Black Sea coast of Ukraine.

Competition in the marketplace. Transportation systems.

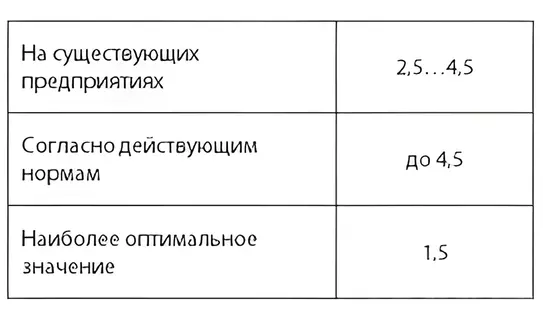

Managers of existing grain terminals are already planning a number of measures to attract potential grain traders and stevedores. Measures such as dredging and expansion of rail lines are already leading to terminals being able to receive and ship larger shipments of grain. However, an important contributing factor is also the modernization of existing transport systems. Transportation mechanisms used during construction 5-10 years ago no longer meet modern performance requirements. A transport system with a capacity of up to 500 tons per hour is capable of handling 1.5-2 million tons of cargo per year. While modern terminals are focused on transshipment of 4-5 million tons, which requires the use of transport mechanisms with a capacity of 1200-1500 t/h.

The competitiveness of a grain elevator is also determined by the price offered for its services. The best price can be offered by the company that has a lower cost of services. When calculating grain logistics at the terminal, we proceed from the initial goal: how much grain does the customer plan to handle per year? On this basis, we calculate:

Dredging volume:

- Capacity of ship loading machine (1200-1500 t/h);

- Capacity of transportation loading and unloading routes (1200-1500 t/h);

- High capacity of car and wagon unloading stations (300-450 wagons per day).

Staging station for container staging

An interesting offer for a business owner will be our development of a container staging station. This is a unique opportunity to carry out transshipment of cargoes at the stage of terminal construction and get profit in a short period of time. As practice shows, with a competent approach, this node can provide up to 60% of the terminal's transshipment capacity by the time it reaches full capacity.

With proper planning of work, one staging area can handle up to 5 thousand tons of grain per day. Today's realities show that due to the shortage of railway cars, we can expect new grain trucks capable of transporting up to 70 tons of grain in the near future.

We are ready to offer a solution for unique high-performance trucks of our own production. Our company has accumulated invaluable experience in correcting incorrect design decisions made by other design organizations, which led to a delay of 1.5-2 years. Our projects exclude such mistakes.

When designing new facilities or reconstructing existing ones, specialists of Grain Capital Group of Companies focus on energy efficiency, minimizing % of grain breakage and environmental safety.

Grain quality. Minimizing grain breakage

An important issue is the prevention of quality losses due to damage, which reduces the technological properties of grain. Particularly relevant is the issue of grain breakage for corn and rice.

Reducing the growth of broken grains in the grain mass can be achieved by an integrated approach to solving the following issues:

- Drying of grain with optimal intensity (not more than 5% in one pass);

- Reducing the length of transportation routes;

- Application of technical means reducing the speed of impacts of grain and working bodies of transport devices: dampers of grain speed in gravity drains and silos; reduced speed of belts, chains, buckets; optimal geometry of loading and unloading elements: spigots of elevators, filling chutes, dumping boxes of conveyors.

In addition to losses in the form of combat, it is also important to ensure stable quality of grain during its storage. The use of optimal modes and technical methods of active ventilation allows to reduce the natural loss of grain and preserve its quality.

Having its own plant for the production of elevator equipment, GC "Grain Capital" successfully implements the most complex projects to increase the productivity of transportation systems of port elevators qualitatively and in a short time, while guaranteeing careful and gentle movement of the product. Over the years, such companies as Ukrkranenergo, Westeel, Symaga, Bonfanti have become our reliable partners in equipment supply.

Complex solutions take into account modern world technologies of equipment dedusting, as well as management of all elevator systems with the help of ACSP programs (reducing the number of working personnel from 150 to 50 people). Service Department of Grain Capital GC has been successfully providing its services to Odessa and Ilyichevsk terminals for the last years.

Round-the-clock maintenance of all systems and mechanisms guarantees uninterrupted operation of the complex during the most critical time of cargo acceptance and shipment. We will be glad to offer you our experience and knowledge in the implementation of effective projects or modernization of existing enterprises, as well as in the construction of new facilities of the grain industry!

Author of the article: Vitaly Galich, Commercial Director of Grain Capital.