Experience in implementing innovative technological solutions

Introduction of innovative technologies to reduce grain losses at modern enterprises

Due to the rapid growth of the world population, the issue of food supply is becoming more and more urgent. The cultivation of cereal crops for food and feed production occupies a key place in the provision of food for the population. Due to the seasonal nature of grain cultivation and constant demand for it, there is a need to create effective conditions for storing its stocks. This process is accompanied by a number of difficulties, because, as we know, the value of bread lies not only in its cultivation, but also in preserving its quality.

Major challenges in grain production and storage:

- Harvesting losses:

If harvesting is delayed, significant losses may occur due to spikelet breakage and shattering of grains. According to research results, the optimal harvesting time is 6-7 days. If this period is violated for 5 days, yield losses of spring wheat can reach 4.5-7.2%, and winter wheat - 1.2-3%. If the delay lasts 10 days, losses increase significantly: up to 15.4% for spring wheat and 6.8% for winter wheat.

- Threshing and storage losses:

Under normal conditions, threshing losses (unthreshing and unthreshing) are about 1.5%. Crushing and collapse of food grain is acceptable within 2%. When transporting and storing crops, losses can vary from 5% to 25% depending on the technical condition of elevators and the organizational culture of the enterprise.

- Total losses:

According to FAO, annual grain losses in the world amount to about 10% of total production, and in some less developed countries these losses can reach 30-50%. In Ukraine, where grain production reaches 30-40 million tons, annual losses due to insufficiently developed material and technical base are up to 8 million tons, which is equivalent to about 800 million USD.

- Decrease in grain quality:

Quantitative losses are often accompanied by a decrease in grain quality. The greatest losses are observed in farms with a low level of logistical support. In highly developed countries of Europe and North America, such losses are limited to 1-2%, which is technically unavoidable minimum.

- Minimization of grain losses:

The greatest grain losses occur during transportation and storage. These losses can be reduced by observing optimal transportation and storage conditions, such as control of grain moisture and temperature, quality cleaning before storage and disinfection of grain mass from pests and microflora. Modern technological solutions that take into account the biological characteristics of crops can significantly reduce losses.

- Modernization of grain cleaning lines:

Most grain enterprises in Ukraine use outdated equipment, which is no longer able to provide the necessary efficiency. The solution to this problem is technical re-equipment with modern grain cleaning lines, which will contribute to reducing grain losses and improving its quality.

- Prevention of grain quality losses:

Special attention should be paid to minimizing grain injury, which can significantly affect its technological properties. This issue is especially relevant for such crops as corn and rice. According to the analysis of Ukrainian enterprises, the increase of corn grain breakage is:

- 4.0-6.5% for procurement enterprises with mobile mechanization and bucket loaders;

- 2.0-4.0% for transshipment elevators with stationary mechanization.

These losses are often associated with non-compliance with technological methods of handling grain.

The average* distribution of germination of breakage by sites of an average operating enterprise is shown in the table:

Average increase of maize grain breakage (with available approach to technology and technique).

| Name of site | Preparatory | Transshipment elevator | ||||

|---|---|---|---|---|---|---|

| Absolute value (from) | Absolute value (k) | % in the total increase in fights at the enterprise | Absolute value (from) | Absolute value (k) | % in the total increase of fights by the enterprise | |

| Gravity transportation | 0,6 | 1,0 | 15,0 | 0,6 | 1,2 | 30,0 |

| Acceptance from motor transport | 0,4 | 0,6 | 9,0 | 0,1 | 0,1 | 3,0 |

| Acceptance from railroad cars | 0,4 | 0,7 | 10,0 | 0,1 | 0,2 | 6,0 |

| Overload points | 1,4 | 2,3 | 36,0 | 0,1 | 0,2 | 5,0 |

| Chain conveyors | 0,2 | 0,3 | 5,0 | 0,1 | 0,3 | 7,0 |

| Norias | 0,4 | 0,7 | 10,0 | 0,2 | 0,4 | 10,0 |

| Tanks (warehouses, silos) | 0,6 | 1,0 | 15,0 | 0,8 | 1,6 | 39,0 |

| Total: | 4,0 | 6,5 | 100,0 | 2,0 | 4,0 | 100,0 |

The data obtained as a result of statistical processing are given, the value of indicators is reduced by the size of the permissible error of analysis methods, the results of experiments, which are within the measurement error, are excluded.

Reducing the growth of broken grains in the grain mass can be achieved with a comprehensive approach to solving the issues:

- grain drying with optimal intensity (no more than 5% per one pass);

- reducing the length of transportation routes;

- application of technical means reducing the speed of collision between grain and working bodies of transportation devices: 1.grain speed dampers in gravity drains and silos; 2.reduced speed of movement: belts, chains, buckets; 3. optimal geometry of loading and unloading elements: spigots of elevators, bulk chutes, discharge boxes of conveyors.

Grain Capital specialists together with "Odessa National Technological University" have developed, passed production tests and recommended for use "Installation of gentle loading of grain into silos".

Job description "Establishing gentle loading of grain into the silo".

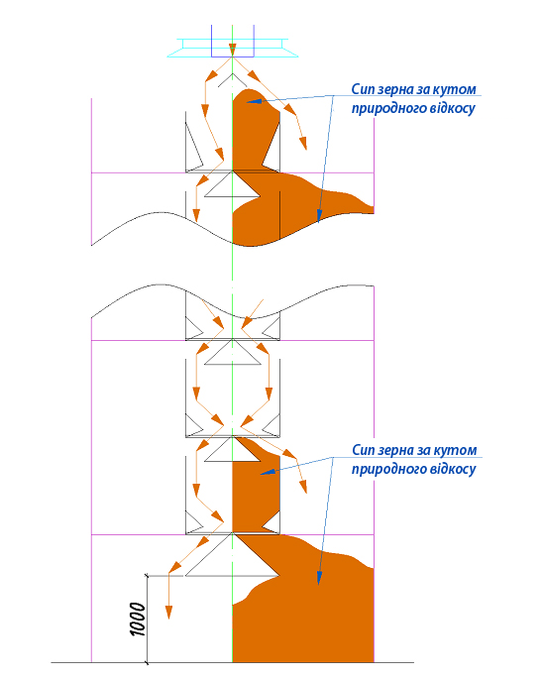

- After the grain enters the loading tube it starts to move, successively overflowing from one inclined plane to another all the way to the bottom of the silo. The free fall height of the grain during the loading process does not exceed 1 meter.

- As the silo fills, the grain level gradually rises until the lower section of the "delicate grain silo loading" unit is filled at a natural slope angle. When the lower section is full, the grain begins to overflow through openings in the sections above onto the embankment already formed below. The free fall height of the grain in this case also does not exceed 1 meter.

- The grain is discharged from the silo by gravity through the central hopper, and the residual grain is removed through the side hoppers and with the help of a scraper auger.

- In addition to preventing losses due to grain damage, it is important to ensure stable grain quality during storage. The use of optimal modes and technical methods of active ventilation allows to reduce natural losses of grain weight and preserve its quality during the entire storage period.

Practical experience of implementation of technological and technical solutions by Grain Capital confirms the possibility to reduce the increase in grain damage by 2.5-4.0 times. Distribution of reduction of damage increment at different sections of the elevator, achieved due to compliance with Grain Capital recommendations, is given in Table 2.

The distribution of reduced* damage increment, by elevator section, achieved by following Grain Capital recommendations.

Average increment of maize grain breakage (with available approach to technology and technique)

| Name of site | Preparatory | Transshipment elevator | ||||

|---|---|---|---|---|---|---|

| Absolute value (from) | Absolute value (k) | % in the total increase in fights at the enterprise | Absolute value (from) | Absolute value (k) | % in the total increase of fights by the enterprise | |

| Gravity transportation | 0,4 | 0,7 | 14,0 | 0,1 | 0,3 | 23,0 |

| Acceptance from motor transport | 0,3 | 0,5 | 10,0 | 0,0 | 0,1 | 7,0 |

| Acceptance from railroad cars | 0,4 | 0,6 | 12,0 | 0,1 | 0,2 | 14,0 |

| Overload points | 1,0 | 1,7 | 33,0 | 0,0 | 0,1 | 4,0 |

| Chain conveyors | 0,2 | 0,3 | 6,0 | 0,1 | 0,2 | 15,0 |

| Norias | 0,4 | 0,6 | 12,0 | 0,1 | 0,3 | 21,0 |

| Tanks (warehouses, silos) | 0,4 | 0,7 | 13,0 | 0,1 | 0,2 | 16,0 |

| Total: | 3,0 | 5,0 | 100,0 | 0,5 | 1,5 | 100,0 |

*The data presented are obtained as a result of statistical processing, the value of indicators is reduced by the size of the permissible error of analysis methods and equipment, the results of experiments that are within the measurement error are excluded.

Comparative characteristics of traditional technological methods and those proposed by Grain Capital are shown in Table 3.

Average effect of grain breakage reduction from application of rational technological solutions

| Name of site | Procurement enterprises | Transshipment elevator | ||

|---|---|---|---|---|

| from | up to | from | up to | |

| Gravity transportation | 1,4 | 1,4 | 3,5 | 5,2 |

| Acceptance from motor transport | 1,2 | 1,2 | 1,1 | 1,7 |

| Acceptance from railroad cars | 1,1 | 1,1 | 1,1 | 1,7 |

| Overload points | 1,4 | 1,5 | 3,3 | 5,0 |

| Chain conveyors | 1,1 | 1,1 | 1,2 | 1,9 |

| Norias | 1,1 | 1,1 | 1,3 | 1,9 |

The greatest effect is given by the introduction of rational techniques and technology in gravity transport, grain transshipment points and in storages with a drop height of grain more than 11 meters.

Conclusion:

Modernization of transport-technological lines of the grain enterprise with use of offers of our experts will allow to reduce quantity of losses of grain on 1...1,5 % for procurement enterprises and on 1,5...2,5 % for transshipment enterprises, only at the expense of reduction of a fight of grain and rationalization of technology. . Which will amount to:

- 100...150 tons of grain at harvesting every 10,000 tons,

- 900...1500 tons of grain when loading each vessel of 60,000 tons capacity

Author of the article: chief engineer-technologist of the design bureau Bilan I.V.