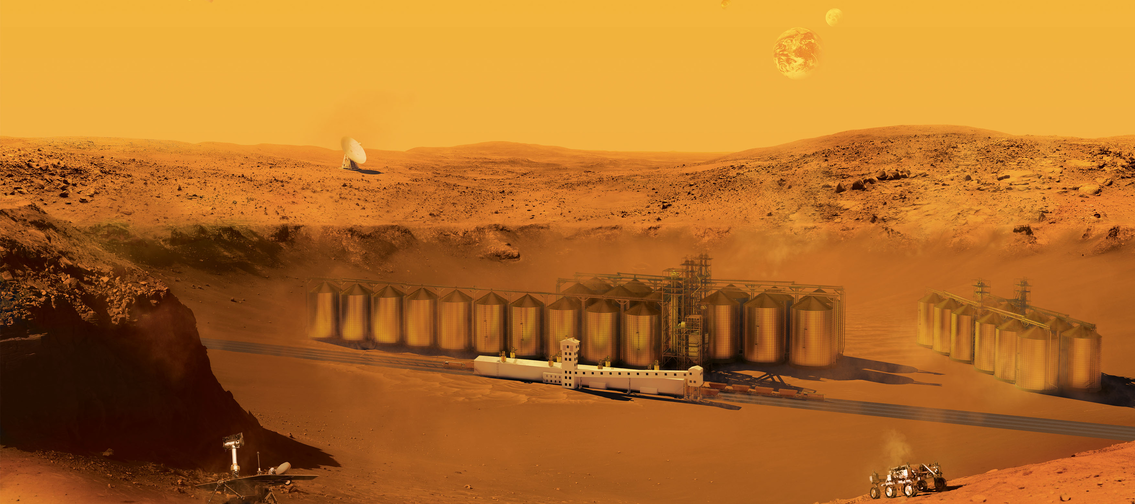

Equipment for a modern grain elevator

Equipment for elevators: is everything imported good for a Ukrainian?

Recently, Ukraine's agricultural sector has been facing new challenges, but despite this it continues to demonstrate high growth rates. Ukraine retains its leading position in the world grain market, ranking among the largest exporters of grain crops, along with such countries as Canada, the USA and Argentina.

Thanks to the introduction of new intensive grain growing technologies, modern tillage and grain harvesting equipment, crop yields are growing annually. This, in turn, requires an increase in grain storage capacity. As of 2024, the gross grain harvest in Ukraine is about 80 million tons, while the simultaneous capacity of elevator facilities has reached about 60 million tons. Although these figures have improved significantly compared to previous years, the shortage of grain storage facilities is still significant, especially given the current challenges related to military operations.

The armed conflict in Ukraine has affected the agricultural sector, in particular logistics and infrastructure. Some elevators were damaged or destroyed, further exacerbating the shortage of storage capacity. However, despite the difficulties, farmers are actively investing in the restoration and modernization of existing facilities, as well as in the construction of new ones.

Previously, when constructing elevators, farms and large agricultural holdings were mainly guided by the cost value, focusing on cost minimization. However, with the development of a competitive environment, the criterion for successful business is the competitiveness of the elevator. What does this mean?

Farmers who sell their crops are looking to maximize their profits. The more elevators available, the more choice a farmer has, and this increases competition between elevators. Under such conditions, competitive price becomes the main tool for attracting customers, which can affect marginal profit. However, it is unprofitable to operate below cost, so elevators are forced to look for ways to improve efficiency, in particular through the introduction of modern equipment and optimization of production processes.

Thus, the choice of equipment for elevators becomes a key factor in ensuring competitiveness, as well as in the successful functioning of agricultural business in Ukraine in the current challenges.

Can you afford to provide a price lower than your competitors?

First of all, it depends on the cost of grain processing and storage. Low cost of production is formed on the basis of a competent project and its completion with high-quality equipment with high efficiency and long service life. Every extra meter of transport equipment and steel structures, every irrationally selected grain silo or incomplete automation system increases the cost of storage.

Today we will consider one of the main factors of elevator competitiveness - quality of technological equipment.

There are three main types of elevator equipment suppliers on the Ukrainian market. Each type of company has its own advantages and disadvantages.

Consider them:

Representatives of foreign manufacturing firms

Benefits:

- The brand of the firm as a whole, which indicates that the firm is consciously responsible with its name for quality.

- Often more advanced equipment manufacturing technology that eliminates the influence of the "human factor" on the production process.

Disadvantages:

- Foreign companies have their representative offices in Ukraine, but are you sure that these representatives (as a rule, the number of not more than 5 people in the staff) will be able to skillfully assemble and select the design of equipment?

- Often the responsibility of representative offices for the supply and quality of products is more formal than actual. For example, you agreed and paid the representative office, then waited several months for the equipment to be manufactured and transported, but during transportation the goods turned out to be damaged or incorrectly assembled. In the best case scenario, you will have to prove your innocence of the damaged goods and wait for a replacement (delivery of up to a month). Even in the case of a successful outcome, you will lose more on simple construction than you will gain on other criteria.

- The price you pay for the brand.

Ukrainian manufacturers

Ukrainian manufacturers

There is a wide competitive field here. Everything depends on the manufacturability and machine-tool base of the machine-building enterprise itself. There are plants that develop and implement their own products, such as "Khorol Mechanical Plant" and "Elevator Equipment Plant" (together with the Odessa National Technological University), and there are those that copy imported analogs, not always fully understanding the principle of device operation. The same situation with the machine tool base of a particular plant - from classical machine tools to automatic lines that exclude the influence of the "human factor".

Advantages of Ukrainian manufacturers:

- Lower price for grain elevator equipment.

- Better service compared to imported suppliers.

Недостатки:

Not all suppliers are equally good, so you need to carefully check the reputation and experience of the manufacturer.

"Garage cooperatives."

Small firms offer very low prices. As a rule, they do not have their own production facilities or have old machines (60-80s). Such firms use the cheapest components (most often from China), the equipment body often looks unreliable, and welds do not stand up to any criticism. Such equipment usually does not meet modern quality requirements and can serve only for a limited time.

Which equipment supplier should I choose?

A review of the situation in the supply of elevator equipment in Ukraine points to several important aspects. Many Ukrainian manufacturers have considerable experience in the production of transportation and gravity equipment, as well as steel structures. However, silo production remains less developed.

Reinforced concrete elevators and brick floor storage warehouses continue to be used, although their resource is close to exhaustion. World trends involving the construction of steel tanks (silos) started to penetrate Ukraine back in the early 90s with the first deliveries from the USA. Today, steel silos are the most popular due to their high efficiency and durability.

Some Ukrainian machine-building enterprises have started production of steel silos, and several projects using domestic silos have already been implemented. However, production technologies and quality have not yet reached European and American standards.

The situation with the production of grain dryers is similar. Imported equipment has proven itself in Ukraine due to high quality standards. The domestic DSP-32 grain dryer is the only one that has won the trust of agrarians for decades, but its capabilities and functionality still have limitations.

Transportation equipment is manufactured in Ukraine at a higher level. Decades of improved technology of conveyors production allows to produce equipment for grain moving, which is not inferior to imported analogs in quality. The use of foreign-made gearmotors and sensors guarantees high reliability and failure-free operation of transporters during the entire period of operation. Service in Ukraine is also more convenient and faster, which is an important factor when harvesting or shipping grain.

As for aspiration equipment, only Grain Capital has a competitive position in the market alongside imported suppliers. Other domestic manufacturers have focused on outdated technologies built on cyclones that no longer meet modern requirements.

In general, we can conclude that in most cases it is more profitable to favor domestic manufacturers, but only those that can provide high quality products, in accordance with modern standards and market requirements.

Elevator equipment from Grain Capital

The quality of work and elevator equipment of Grain Capital and "Plant of Elevator Equipment" is confirmed by a wide customer base, which is growing daily, and positive feedback from our customers. Among them are such international grain trading companies as Alfred S. Topfer, Serna, Cargill, Bunge and Souffle, which have the most stringent requirements to the quality of equipment. We are constantly working to improve our technology to meet the highest quality standards.

Our success is also due to the implementation of an effective ISO 9001:2008 quality management system, which ensures high reliability and efficiency of our equipment. This has allowed us to gain the trust of our customers and maintain an impeccable reputation as a responsible and professional business partner. Our regular customers include such companies as United Elevator Company LLC (34 elevators), Agrotrade LLC (7 elevators), Servis-Grain LLC, which have been noting the high quality and reliability of our services and equipment for several years.

We strive for constant development and improvement of our products and services to meet the latest trends and market requirements. You can ask the author of this article additional questions personally by contacting him by e-mail: galich@zeo.ua.