Highly efficient gravity transport systems

Highly efficient gravity transportation systems are the reliability of a modern elevator complex.

Grain processing industry is developing, and as a consequence, most enterprises of the industry face the issue of increasing the volume of grain acceptance and processing. Due to the increase in the intensity of operation of transportation and technological lines, wear and tear is increasing not only of transportation (belt conveyor, scraper conveyor, screw conveyor, elevator, etc.), but above all of gravity equipment.

Modern gravity transportation systems

Gravity conveying systems integrate major process operations and lines. They consist of basic fittings standardized in our industry, such as pipes, sectors, transitions, inlets, product request elements of process equipment.

Wear and tear of gravity equipment

The wear and tear of gravity equipment is due to these basic design parameters of the equipment:

- Body material (steel type)

- Technological location

- Equipment manufacturing technology

- Equipment installation technology

- Construction geometry

- No lining

The operation of the gravity conveying systems of each company can be compared to the human circulatory system. Therefore, it is very important that the "arteries" of each elevator have such a property as durability.

Main reasons for decreased durability of gravity equipment

- Use of steel grades with low friction resistance and low hardness.

- Presence of curvature, burrs and gradients on the working surfaces of the equipment.

- Neglect by manufacturers of normative characteristics of geometry and thickness of the body of the equipment element.

- Lack of wear-resistant coatings of working surfaces.

- Violation of production technology.

Important durability criteria

The most important criterion for durability is the grade of steel used. The main type of destruction of the hull of gravity conveying systems is the reduction of the hull wall thickness by intensive abrasion with an abrasive product. Abrasion is the flaking off of steel particles by physical and mechanical action. The main factor for abrasion is the grain size of the steel.

Production of gravity-flow equipment

Today on the territory of Ukraine there are so-called garage cooperatives for the production of gravity equipment, which sell their products at an undervalued price. However, these products do not meet the requirements of modern elevator industry due to the lack of proper production facilities and machine-tool base.

Selecting gravity flow equipment

When selecting gravity equipment, attention should be paid to the following:

- Integrity of the housing element blank (in the case of production from jointed sheets, additional irregularities and burrs are formed, causing intensification of wear).

- Location of the joints (the joint must be in direct contact with the product).

- Metal thickness (some manufacturers use 1.8 mm steel instead of 2 mm or 2.5 mm instead of 3 mm).

- Perpendicularity of flanges to the body of the element (lack of perpendicularity leads to a change in the trajectory of the product, which negatively affects the body elements of gravity transport).

- Location of holes on the flanges.

- Material of flanges (the joint of two elements is weakened by welds and geometry difference, so it is extremely important that the joint is reinforced with angle steel).

- Installation of gravity transport elements.

What you need to pay attention to during installation:

- Alignment: The alignment of the shaped elements almost completely prevents curvature of the path and chaotic spreading of the grain material. Compliance with this rule will extend the service life of the gravity conveyor and reduce the loss of conditioned product.

- Concentricity: Concentricity is the coincidence and subsequent repetition of the working surfaces when assembling the gravity track. Failure to observe this rule will intensify abrasion and fracture of the gravity element housing.

- Composition of gravity lines: The fewer bends and turns in the line, the longer the service life of the line and the better the quality of the transported product.

Correct operation and proper maintenance

Every year, every business is faced with the repair and replacement of gravity equipment. In the case of gravity transport, proper operation is the maximum operating time until destruction without stopping for repairs. And long-life operation is only possible if the above recommendations are followed.

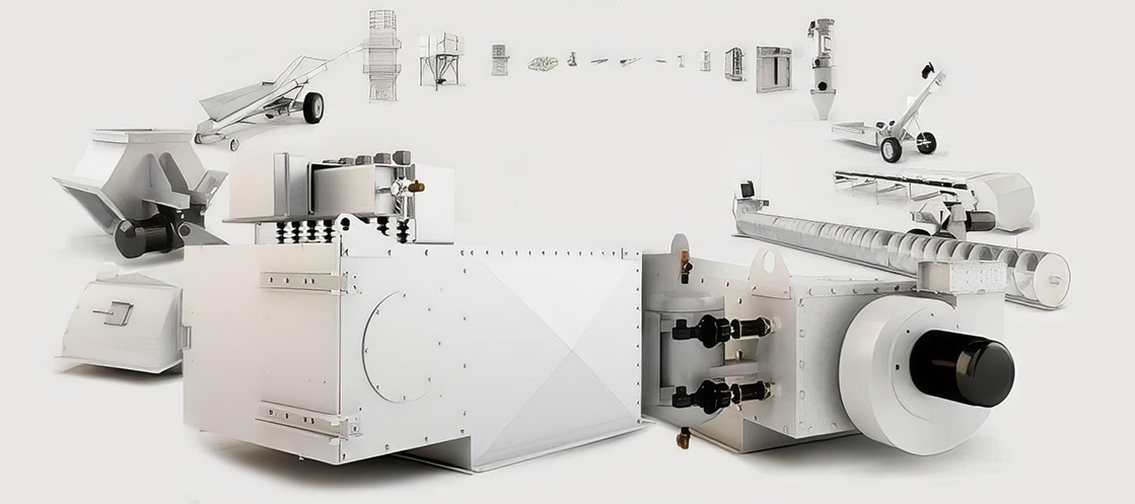

Innovative solutions from Grain Capital

Knowing and taking into account the existing problems, Grain Capital offers a package of services for supply and installation of durable and wear-resistant gravity transport, analogues of which do not exist in Ukraine.

Read more about gravity transportation equipment: https://zeo.ua/en/katalog-obladnannya/samoplivne-obladnannya

Author of the article: Director of Development at Grain Capital, Igor Gaponyuk.